8

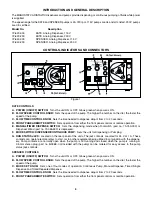

USING THE DISPENSER WAND OR FOOTSWITCH

1. Insert the output end of the tubing coming from the pump head through the glass holder of the dispenser wand.

Wetting the tip of the tubing will facilitate insertion.

2. Insert a dispensing tip into the end of the tubing. This step will improve accuracy by reducing dripping (See

ACCESSORIES

).

3. Plug the dispenser wand electrical cord into the socket (DB9) on the rear of the unit. (If a footswitch is being used

instead of the dispenser wand, plug the footswitch cord into the same socket.)

4. Check the rear panel label for proper position of the “FRONT PANEL/REMOTE” switch.

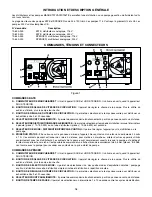

PRIMING TUBING AND CONTINUOUS PUMPING MODE

1. Insert appropriate size tubing into pump head and set up with dispenser wand or footswitch. (To select tubing size,

see

TUBING SIZE SELECTION

.)

2. Insert both intake and output ends of tubing in reservoir to prime.

3. Adjust Flow Speed Control Knob to a setting of ‘1’.

4. Set Mode Switch or Knob to “CONTINUOUS PUMP”.

5. Turn Power Switch to ON.

CAUTION:

When changing flow direction, allow the pump to come to a complete stop before starting again.

Failure to do so could cause permanent damage to the motor.

6. Turn Flow Speed Control Knob clockwise to start the pumping action. The higher the number selected, the faster the

speed of the pump. Prime new tubing for at least 5 minutes to achieve a stable flow condition.

CALIBRATION PROCEDURE AND MANUAL DISPENSING OPERATION

Refer to

DISPENSING VOLUME TUBING REQUIREMENTS

to select appropriate size tubing. Insert tubing into the

pump head. Prime tubing with liquid (See

PRIMING TUBING AND CONTINUOUS PUMPING MODE

section above).

Materials needed: Graduated cylinder (or other measuring device), timing device or watch with second hand.

1.

For KATE:

Set the Mode Switch to “DISPENSER” and the Manual/Timed Dispense Switch to “MANUAL”.

For SPENCER:

Set the Mode Set Knob to “MANUAL DISPENSE”.

2. Set Flow Speed Control Knob to ‘1’.

3. Set Power Switch to ON.

CAUTION:

When changing flow direction, allow the pump to come to a complete stop before starting again.

Failure to do so could cause permanent damage to the motor.

4. To begin pumping action, depress the button on the dispenser wand (or footswitch) and hold. Increase flow speed

knob (clockwise) to adjust to a desired flow. When desired flow is achieved or desired volume is reached, release the

button or footswitch to stop pumping action.

5.

For Calibrating:

Place the outlet tubing into the graduated cylinder. Depress the button on the dispenser wand (or

footswitch) and time how long it takes to reach the desired volume. As soon as the volume is reached, release the

button and note the time it took to dispense in seconds.

CALIBRATION CHECK AND TIMED DISPENSING OPERATION

Refer to

DISPENSING VOLUME TUBING REQUIREMENTS

to select the appropriate size tubing and insert into pump

head. Prime tubing with liquid (See

PRIMING TUBING AND CONTINUOUS PUMPING MODE

).

Material needed: Graduated cylinder (or other measuring device).

1. Set Flow Speed Control Knob to ‘1’.

2. Set Power Switch to ON.

CAUTION:

When changing flow direction, allow the pump to come to a complete stop before starting again.

Failure to do so could cause permanent damage to the motor.

3. Set Mode Switch to “CONTINUOUS PUMP”.

4. Increase Flow Speed Control Knob (clockwise) to begin pumping action. Adjust to desired flow or set to the flow that

was used in the

CALIBRATION PROCEDURE AND MANUAL DISPENSING OPERATION

.

Содержание VARISTALTIC KATE 72-620-000

Страница 2: ...2 VARISTALTIC...