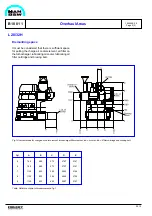

L28/32H

B 10 01 1

1605544-1.5

Page 3 (5)

General Description

through the cylinder liner. The joint faces on con-

necting rod and bearing cap are serrated to ensure

precise location and to prevent relative movement of

the parts.

The connecting rod has bored channels for supply of

oil from the big-end to the small-end eye.

The big-end bearing is of the trimetal type coated

with a running layer.

The bearing shells are of the precision type and are

therefore to be fitted without scraping or any other

kind of adaption.

The small-end bearing is of trimetal type and is

pressed into the connecting rod. The bush is

equipped with an inner circumferential groove, and

a pocket for distribution of oil in the bush itself and for

supply of oil to the pin bosses.

Crankshaft and Main Bearings

The crankshaft, which is a one-piece forging, is

suspended in underslung bearings. The main bear-

ings are of the trimetal type, which are coated with a

running layer. To attain a suitable bearing pressure

and vibration level the crankshaft is provided with

counterweights, which are attached to the crank-

shaft by means of dovetail joints and secured with a

centrally placed screw.

At the flywheel end the crankshaft is fitted with a gear

wheel which through an intermediate wheel drives

the camshaft.

Also fitted here is a coupling flange for connection of

a generator. At the opposite end (front end) there is

a claw-type coupling for the lub. oil pump or a flexible

gear wheel connection for lub. oil and water pumps.

Lubricating oil for the main bearings is supplied

through holes drilled in the engine frame. From the

main bearings the oil passes through bores in the

crankshaft to the crankpin bearings and hence

through channels in the connecting rods to lubricate

the piston pins and cool the pistons.

Vibration Damper

96.12

In special cases a vibration damper is mounted on

the crankshaft to limit torsional vibrations. The

damper consists essentially of a heavy flywheel

totally enclosed in a light casing.

A small clearance is allowed between the casing and

the flywheel, and this space is filled with a highly

viscous fluid. The casing is rigidly connected to the

front end of the engine crankshaft and the only

connection between the crankshaft and the damper

flywheel is through the fluid. Under conditions of no

vibration, the casing and damper flywheel tend to

rotate as one unit, since the force required to shear

the viscous film is considerable. As the torsional

vibration amplitudes increase, the casing follows the

movement of the crankshaft but the flywheel tends to

rotate uniformly by virtue of its inertia, and relative

motion occurs between the flywheel and the casing.

The viscous fluid film therefore undergoes a shear-

ing action, and vibration energy is absorbed and

appears as heat.

Camshaft and Camshaft Drive

The inlet and exhaust valves as well as the fuel

pumps of the engine are actuated by a camshaft.

The camshaft is placed in the engine frame at the

control side (left side, seen from the flywheel end).

The camshaft is driven by a gear wheel on the crank-

shaft through an intermediate wheel, and rotates of

a speed which is half of that of the crankshaft.

The camshaft is located in bearing bushes which are

fitted in bores in the engine frame, each bearing is

replaceable and locked in position in the engine

frame by means of a locking screw.

A guidering mounted at the flywheel end guides the

camshaft in the longitudinal direction.

Each section is equipped with fixed cams for opera-

tion of fuel pump, air inlet valve and exhaust valve.

The foremost section is equipped with a splined shaft

coupling for driving the fuel oil feed pump (if

mounted). The gear wheel for driving the camshaft

as well as a gear wheel connection for the governor

are screwed on to the aftmost section.

Содержание L28/32H

Страница 4: ......

Страница 5: ...Introduction I 00...

Страница 6: ......

Страница 8: ......

Страница 10: ......

Страница 11: ...Designation of Cylinders In Line 98 19 1607568 0 1 Page 1 1 I 00 15 0...

Страница 12: ......

Страница 18: ......

Страница 19: ...General information D 10...

Страница 20: ......

Страница 22: ......

Страница 24: ......

Страница 26: ......

Страница 30: ......

Страница 32: ......

Страница 34: ......

Страница 36: ......

Страница 37: ...Basic Diesel Engine B 10...

Страница 38: ......

Страница 44: ......

Страница 45: ...99 40 B 10 01 1 L28 32H Cross Section 1607528 5 2 Page 1 1...

Страница 46: ......

Страница 48: ......

Страница 50: ......

Страница 52: ......

Страница 54: ......

Страница 58: ......

Страница 59: ...1607566 7 1 Page 1 1 Engine Rotation Clockwise B 10 11 1 General 98 18...

Страница 60: ......

Страница 61: ...Fuel Oil System B 11...

Страница 62: ......

Страница 65: ...08028 0D H5250 94 08 12 General Fuel Oil Diagram B 11 00 0 1624468 9 4 Page 1 3 99 33 Fig 1 Fuel oil diagram...

Страница 68: ......

Страница 72: ......

Страница 74: ......

Страница 76: ......

Страница 79: ...Lubrication Oil System B 12...

Страница 80: ......

Страница 86: ......

Страница 88: ......

Страница 91: ...Cooling Water System B 13...

Страница 92: ......

Страница 98: ......

Страница 106: ......

Страница 108: ......

Страница 112: ......

Страница 113: ...Compressed Air System B 14...

Страница 114: ......

Страница 118: ......

Страница 119: ...Combustion Air System B 15...

Страница 120: ......

Страница 124: ......

Страница 126: ...Fig 1 Jet system 1639456 5 0 Page 2 2 Lambda Controller 93 44 L28 32H B 15 11 1...

Страница 127: ...Exhaust Gas System B 16...

Страница 128: ......

Страница 132: ...08028 0D H5250 94 08 12 General 1607517 7 4 Page 2 2 Water Washing of Turbocharger Turbine B 16 01 1 98 20...

Страница 136: ......

Страница 140: ......

Страница 142: ......

Страница 144: ......

Страница 146: ......

Страница 147: ...Speed Control System B 17...

Страница 148: ......

Страница 150: ......

Страница 152: ......

Страница 153: ...Monitoring Equipment B 18...

Страница 154: ......

Страница 156: ......

Страница 158: ......

Страница 159: ...Safety and Control System B 19...

Страница 160: ......

Страница 164: ......

Страница 166: ......

Страница 177: ...Foundation B 20...

Страница 178: ......

Страница 180: ......

Страница 183: ...Test running B 21...

Страница 184: ......

Страница 186: ......

Страница 187: ...Spare Parts E 23...

Страница 188: ......

Страница 190: ......

Страница 191: ...99 35 1607521 2 6 Page 1 1 Recommended Wearing Parts E 23 04 0 L28 32H...

Страница 192: ......

Страница 195: ...Tools P 24...

Страница 196: ......

Страница 200: ......

Страница 202: ......

Страница 203: ...Preservation and Packing B 25...

Страница 204: ......

Страница 206: ......

Страница 208: ......

Страница 210: ......

Страница 211: ...Alternator G 50...

Страница 212: ......

Страница 216: ......

Страница 218: ......