91.32

General

1609535-5.1

Page 1 (2)

Exhaust Gas System

B 16 00 0

Internal exhaust gas system

From the exhaust valves, the gas is led to the

exhaust gas receiver where the fluctuating pressure

from the individual cylinders is equalized and the

total volume of gas led further on to the turbocharger,

at a constant pressure. After the turbocharger, the

gas is led to the exhaust pipe system.

The exhaust gas receiver is made of pipe sections,

one for each cylinder, connected to each other, by

means of compensators, to prevent excessive stress

in the pipes due to heat expansion.

In the cooled intermediate piece a thermometer for

reading the exhaust gas temperature is fitted and

there is also possibility of fitting a sensor for remote

reading.

To avoid excessive thermal loss and to ensure a

reasonably low surface temperature the exhaust

gas receiver is insulated.

External exhaust gas system

The exhaust back-pressure should be kept as low as

possible.

It is therefore of the utmost importance that the

exhaust piping is made as short as possible and with

few and soft bends.

Long, curved, and narrow exhaust pipes result in

higher back-pressure which may affect the engine

combustion.

The exhaust back-pressure should not exceed 250

mmWC at MCR. An exhaust gas velocity through the

pipe of maximum 35 m/sec is often suitable, but

depends on the actual piping.

Holeby will be pleased to assist in making a calcula-

tion of the exhaust back-pressure.

The gas outlet of turbocharger, the expansion bel-

lows, the exhaust pipe, and silencer, (in case of

silencer with spark arrestor care must be taken that

the cleaning parts are accessible), must be insula-

ted with a suitable material.

The insulation should be shielded by a thin plating,

and should comply with the requirements of the

classification society and/or the local authorities.

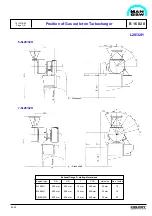

Exhaust pipe dimensions

It should be noted that concerning the maximum

exhaust gas velocity the pipe dimension after the

expansion bellow should be increased for some of

the engines.

The wall thickness of the external exhaust pipe

should be min. 3 mm.

Exhaust pipe mounting

When the exhaust piping is mounted, the radiation of

noise and heat must be taken into consideration.

Because of thermal fluctuations in the exhaust pipe,

it is necessary to use flexible as well as rigid

suspension points.

In order to compensate for thermal expansion in the

longitudinal direction, expansion bellows must be

inserted. The expansion bellows should preferably

be placed at the rigid suspension points.

Note: The exhaust pipe must not exert any force

against the gas outlet on the engine.

One sturdy fixed-point support must be provided for

the expansion bellows on the turbocharger. It should

be positioned, if possible, immediately above the

expansion bellow in order to prevent the transmis-

sion of forces, resulting from the weight, thermal

expansion or lateral displacement of the exhaust

piping, to the turbocharger.

The exhaust piping should be mounted with a slope

towards the gas outlet on the engine. It is recom-

mended to have drain facilities in order to be able to

remove condensate or rainwater.

Содержание L28/32H

Страница 4: ......

Страница 5: ...Introduction I 00...

Страница 6: ......

Страница 8: ......

Страница 10: ......

Страница 11: ...Designation of Cylinders In Line 98 19 1607568 0 1 Page 1 1 I 00 15 0...

Страница 12: ......

Страница 18: ......

Страница 19: ...General information D 10...

Страница 20: ......

Страница 22: ......

Страница 24: ......

Страница 26: ......

Страница 30: ......

Страница 32: ......

Страница 34: ......

Страница 36: ......

Страница 37: ...Basic Diesel Engine B 10...

Страница 38: ......

Страница 44: ......

Страница 45: ...99 40 B 10 01 1 L28 32H Cross Section 1607528 5 2 Page 1 1...

Страница 46: ......

Страница 48: ......

Страница 50: ......

Страница 52: ......

Страница 54: ......

Страница 58: ......

Страница 59: ...1607566 7 1 Page 1 1 Engine Rotation Clockwise B 10 11 1 General 98 18...

Страница 60: ......

Страница 61: ...Fuel Oil System B 11...

Страница 62: ......

Страница 65: ...08028 0D H5250 94 08 12 General Fuel Oil Diagram B 11 00 0 1624468 9 4 Page 1 3 99 33 Fig 1 Fuel oil diagram...

Страница 68: ......

Страница 72: ......

Страница 74: ......

Страница 76: ......

Страница 79: ...Lubrication Oil System B 12...

Страница 80: ......

Страница 86: ......

Страница 88: ......

Страница 91: ...Cooling Water System B 13...

Страница 92: ......

Страница 98: ......

Страница 106: ......

Страница 108: ......

Страница 112: ......

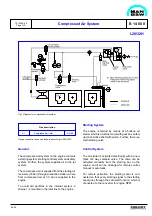

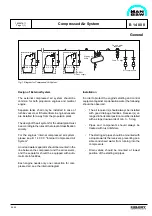

Страница 113: ...Compressed Air System B 14...

Страница 114: ......

Страница 118: ......

Страница 119: ...Combustion Air System B 15...

Страница 120: ......

Страница 124: ......

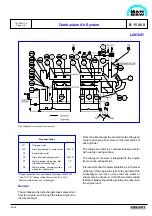

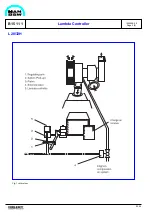

Страница 126: ...Fig 1 Jet system 1639456 5 0 Page 2 2 Lambda Controller 93 44 L28 32H B 15 11 1...

Страница 127: ...Exhaust Gas System B 16...

Страница 128: ......

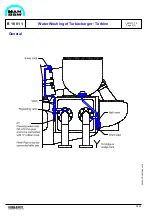

Страница 132: ...08028 0D H5250 94 08 12 General 1607517 7 4 Page 2 2 Water Washing of Turbocharger Turbine B 16 01 1 98 20...

Страница 136: ......

Страница 140: ......

Страница 142: ......

Страница 144: ......

Страница 146: ......

Страница 147: ...Speed Control System B 17...

Страница 148: ......

Страница 150: ......

Страница 152: ......

Страница 153: ...Monitoring Equipment B 18...

Страница 154: ......

Страница 156: ......

Страница 158: ......

Страница 159: ...Safety and Control System B 19...

Страница 160: ......

Страница 164: ......

Страница 166: ......

Страница 177: ...Foundation B 20...

Страница 178: ......

Страница 180: ......

Страница 183: ...Test running B 21...

Страница 184: ......

Страница 186: ......

Страница 187: ...Spare Parts E 23...

Страница 188: ......

Страница 190: ......

Страница 191: ...99 35 1607521 2 6 Page 1 1 Recommended Wearing Parts E 23 04 0 L28 32H...

Страница 192: ......

Страница 195: ...Tools P 24...

Страница 196: ......

Страница 200: ......

Страница 202: ......

Страница 203: ...Preservation and Packing B 25...

Страница 204: ......

Страница 206: ......

Страница 208: ......

Страница 210: ......

Страница 211: ...Alternator G 50...

Страница 212: ......

Страница 216: ......

Страница 218: ......