[3] DISASSEMBLY/ ASSEMBLY

[3]-2. Inner cover (cont.)

[3]-3. Grip

R

epair

P 1

0

/

18

Assemble by reversing the disassembly procedure.

Note:

•

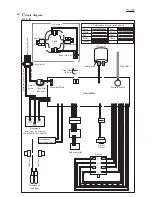

When installing Seal ring onto Tank cover complete, put the protruding portion of the ring in the depressed portion of

Tank cover complete, then apply ThreeBond 1215 to the portion as shown on the left of

Fig. 29

.

• When installing Rubber ring onto Tank cover complete, fit the groove of the ring firmly over the fitting rib of Tank

cover complete as shown on the right of

Fig. 29

.

ASSEMBLING

(1) Put the pivot pin of one end of Grip in the pivot hole on the rear side

of Cowling complete.

(2) While prying the other end of Grip with a slotted screwdriver

as you did in step (3) of "DISASSEMBLING", put the pivot pin

in the pivot hole on the front side of Cowling complete.

(1) Put Grip in the retracted position.

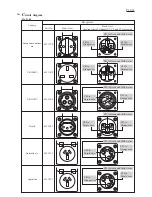

(2) Insert a slotted screwdriver between Grip and Cowling complete,

then pry Grip in the direction of the white arrow to disengage

the pivot pin of Grip from the hole of Cowling complete. (

Fig. 30

)

(3) While prying with the screwdriver, remove Grip by lifting it

upwards.

ASSEMBLING

Fig. 29

Tank cover complete,

viewed from bottom

Seal ring

Rubber ring

DISASSEMBLING

Fig. 30

Pivot pin of Handle

Cowling complete

Grip

Note:

When prying Grip with a slotted screwdriver, be careful not to

damage the surface of Grip or Cowling complete. An so it is highly

recommended to wrap a rag around the screwdriver.

groove of Rubber ring