4 - 6

('*(

3UH,QVWDOODWLRQ*XLGH

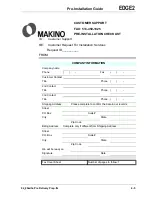

Pre-Installation Checklist

page 2

Request ID number

Machine

Model: EDGE2

Control Type:

MGF

Serial #

Please indicate the completion of the following items with a “Y” in the space provided. If there is a ques-

tion or problem with any item listed below, it should be addressed immediately by contacting your dis-

tributor, sales representative, or Makino,

before

a Field Service Engineer is scheduled to supervise

installation of the machine.

1.

Packing list checked. Check that all parts, manuals, keys, tool kit, schematics, etc., have

been received (in addition to immediately contacting Makino, note any discrepancies on a

separate sheet and include with this document. Take pictures of any shipping damage).

2.

Machine condition checked. The condition of the machine proper and all system components

has been inspected for damage or other unacceptable conditions (in addition to immediately

contacting Makino, note any discrepancies on a separate sheet, send to the shipper, and

include with this document).

3.

Machine placed on proper foundation clear of all obstructions and rough leveled.

4.

Machine is clean. The machine, components, and accessories are unpacked, inspected, and

cleaned (corrosion preventative and dirt removed by wiping with a safe, clean solvent).

5.

Power cables are installed. 3-phase 240-480 VAC source voltage has been routed and con-

nected to the main disconnect.

WARNING!

Do NOT apply power to the machine at this

time (the FSE will verify proper wiring prior to power up).

6.

Air is available. Permanent air lines should be run to the machine vicinity (if uncertain where

to route the air line, please ensure that clean and dry air is available for a temporary connec-

tion for installation and training purposes).

7.

Cutting fluid is available. Always use a highly refined oil with a minimum of PAH’s. Do not fill

the dielectric tank prior to the FSE’s request.

8.

Proper Earth Ground is connected. Earth Ground should be routed via any convenient path

and attached to the machine's ground buss, inside the MTC (Machine Tool Cabinet).

9.

Maintenance personnel selected and scheduled to assist the FSE with the installation (this is

an excellent opportunity for exposure and learning. If required, riggers and millwrights are

scheduled or available on short notice).

10.

A precision level (0.0005in./ft.) is available for set-up. If not available, contact your distributor

or sales representative (this equipment is required for proper periodic maintenance. Makino

recommends this equipment be acquired, if not currently owned).

11.

1. A part has been selected, and a part program is written and ready.

2. Proper fixturing is ready.

12.

Operators and Maintenance personnel selected and available for training.

Содержание EDGE-2

Страница 8: ...vi 3UH QVWDOODWLRQ XLGH...

Страница 11: ...01_20ed3aSafety fm 3UH QVWDOODWLRQ XLGH 1 11 Installation Safety Instructions 1 25...

Страница 12: ...3UH QVWDOODWLRQ XLGH NOTES SKETCHES...

Страница 34: ...1 22 3UH QVWDOODWLRQ XLGH FIGURE 1 4 OILMATIC SAFETY LABELS...

Страница 38: ...1 26 3UH QVWDOODWLRQ XLGH NOTES SKETCHES...

Страница 63: ...02_20ed3a Specifications fm 2 23 3UH QVWDOODWLRQ XLGH NOTES SKETCHES...

Страница 64: ...2 24 3UH QVWDOODWLRQ XLGH...

Страница 74: ...3 8 3UH QVWDOODWLRQ XLGH NOTES SKETCHES...

Страница 79: ...04_20ed3a Pre Delivery Prep fm 4 3 3UH QVWDOODWLRQ XLGH NOTES SKETCHES...

Страница 87: ...04_20ed3a Pre Delivery Prep fm 4 11 3UH QVWDOODWLRQ XLGH NOTES SKETCHES...

Страница 88: ...4 12 3UH QVWDOODWLRQ XLGH NOTES SKETCHES...

Страница 103: ...05_20ed3a Machine Delivery fm 5 13 3UH QVWDOODWLRQ XLGH NOTES SKETCHES...

Страница 104: ...5 14 3UH QVWDOODWLRQ XLGH NOTES SKETCHES...

Страница 112: ...SSHQGL A 6 NOTES SKETCHES...

Страница 120: ...SSHQGL A 14 NOTES SKETCHES...