Page 4 of 20

507389-02

Issue 1733

Installing without a Wall Sleeve

Refer to the following directions and Figure 1 for guidance

in installing the unit without a wall sleeve:

1.

Measure the size of the unit and provide an opening

in an outside wall that will accept the unit. Local

ordinances may require a steel lintel to support the

wall above the opening. The opening must be square

in all four corners.

2. Position the unit so that the grilles on the outside face

of the unit are flush or extend beyond the face of the

exterior wall, but not recessed more than 2” from the

face of the building. Provide a support under the unit,

inside the building. Make sure that the inside support

does not block the return air. The unit should be

installed level or pitched slightly to the outside of the

building so that rain water will drain away.

3. Seal the space between the unit and building opening

using a non-hardening caulking compound. The seal

must be weather-tight to prevent entrance of moisture

and water into the building. Make sure the drain holes

in the base are not plugged with caulking.

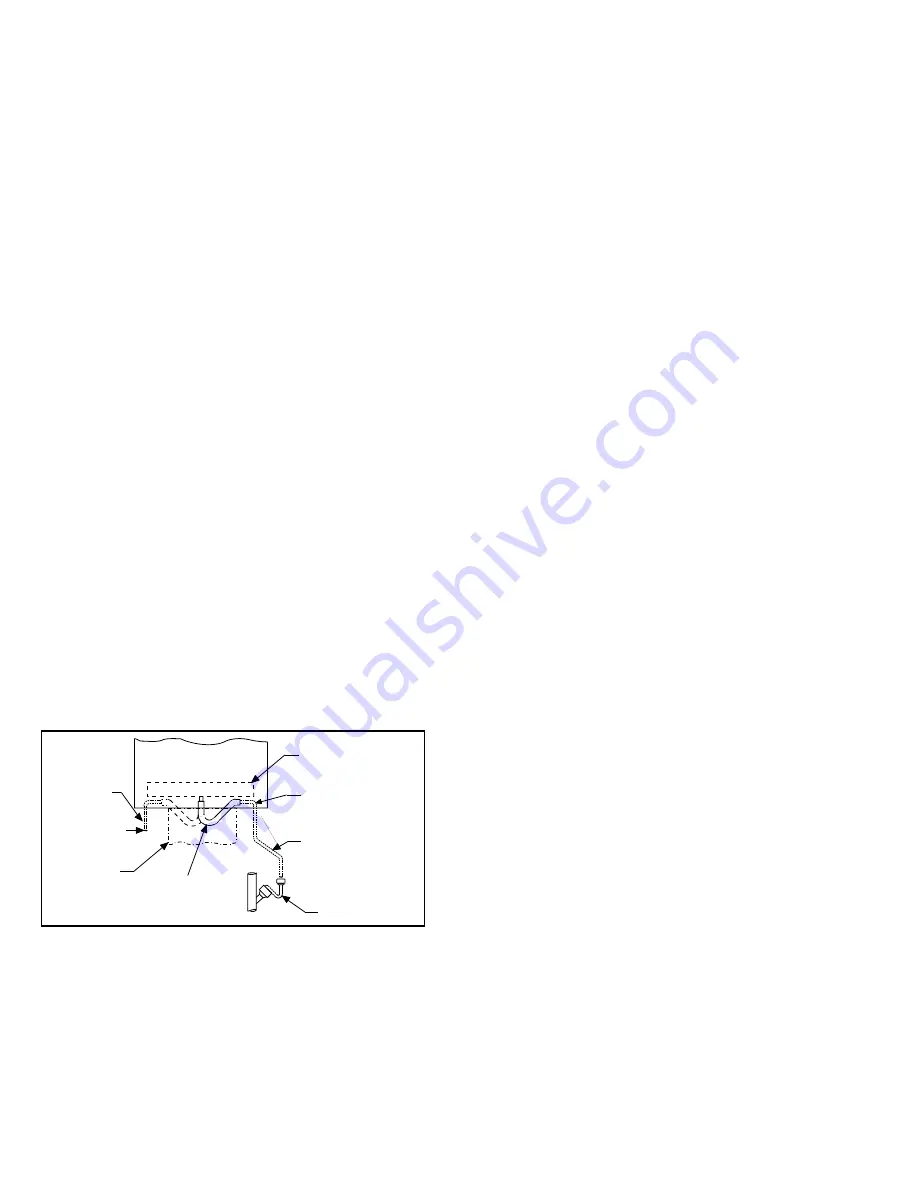

Evaporator Condensate Drain

Install the plastic drain tube (furnished) over the 5/8” O.D.

fitting in the center of the Evaporator condensate pan.

Connect other end of the drain tube to the open trap (see

Figure 2). The plastic drain connection is provided so that

it may be disconnected from the permanent drain tubing in

the building in the event it becomes necessary to remove

the cooling chassis assembly.

The drain line should pitch gradually downward at least 1”

per 10’ of horizontal run to the open drain trap.

Be certain that the plastic drain tube has free drainage and

is not crimped or flattened at any bend.

Figure 2. HWC Evaporator Condensate Drain

Installation

Drain Pan

Open Drain Trap

Return

Air Duct

To Open

Drain Trap

Alternative

Method

5/8

" I.D.

Plastic Tube

(Supplied)

Top of Drain Tube

Must be Below

Bottom of Drain Pan

Drain Tube - Pitch 1"

for every 10 ft.

(Field Supplied)

Furnace Condensate Drain

The HWC9 furnace is provided with an internal condensate

drain and drain fitting. A street elbow, a hose barb and a

spigot adapter for connection to the drain fitting are factory-

supplied in the manual bag. All other piping is field-supplied

to suit the installation and local codes.

If the furnace is installed in an unconditioned space, the

condensate drain elbow outside the unit cabinet must

have heat tape suitable for PVC pipe installed, and the

elbow insulated. This heat tape and insulation are field-

supplied from standard hardware items that are available

locally, and they must be installed in accordance with the

instructions provided by their manufacturers.

Units are shipped with the drain fitting installed for side-exit

condensate drainage. The drain fitting can be repositioned

for front-exit condensate drainage if desired. Do not

relocate or remove the internal condensate trap.

If unit will be started immediately upon completion of

installation, the drain must be primed as described in the

procedure outlined in the “Start-up” section.

Field-installed piping from the furnace must slope downward

a minimum of 1/2” per foot toward the floor drain.

Piping for Side-Exit Condensate Drain

Determine whether the installation better suits a side-exit or

a front-exit furnace condensate drain. For side condensate

drain, see Figure 3 for component locations and additional

details. A 2” clearance to the cabinet side is required for

service access to the condensate drain fitting when using

the side location.

1. Install the factory-supplied street elbow to the drain

fitting by threading into place. Use a thread sealant

suitable for PVC; do not use thread tape.

2. Use the appropriate primer and solvent cement to

bond field-supplied drain line piping or fittings to the

PVC street elbow. Do not use copper tubing or existing

copper condensate lines for drain line.

3.

Route the piping to an open floor drain. Do not connect

directly to evaporator condensate drain line.

Piping for Front-Exit Condensate Drain

For front condensate drain, see Figure 4 for component

locations and additional details. Use the factory-supplied

hose barb with field-supplied flexible tubing or spigot and

hose coupling for these installations. A 2” or 4”(depending

of choice of fittings) clearance to the cabinet front is

required for service access when using the front location.

The modifications necessary to convert to front-exit

condensate drain are:

1.

Disconnect the lower drain hose from the drain fitting.

2.

Remove the screw securing the drain fitting to the

division panel.

3.

Remove the drain fitting and rotate it so that it faces

the front of the furnace.

4. Replace the securing screw.

5. Disconnect lower drain hose from drain trap and rotate

the hose so that the angled end will connect to the

drain fitting in its new orientation.