6

0698-825 MD1xL / MD2xL - 06/2021

en

Personnel qualification

• This device must not be used by children. It may

be used by persons of reduced physical, senso-

ry or mental capacity or by persons lacking in

experience or knowledge provided that they are

supervised or have been instructed in the safe

use of the device and understand the associated

hazards. Cleaning or user maintenance must not

be performed by children.

• Ensure that personnel tasked with work on

the motor have read and understood these

instructions and all associated applicable

documents, particularly safety, maintenance and

servicing information, before they start work.

• Clarify responsibilities, competencies and mon-

itoring of the personnel.

• Ensure that all work is carried out by technical

qualified personnel only:

- Assembly, servicing, maintenance work

- Work on the electrics

• Personnel to be trained must only work on the

motor under the supervision of technical person-

nel.

• Personnel holding the motor in their hands

during operation will be subjected to vibrations.

Statutory warranty

• During the guarantee period, obtain the manu-

facturer's permission for modifications, mainte

-

nance work or alteration.

• Use only original parts.

Duties of the personnel

• Observe the notices on the motor and maintain

them in a legible state.

• Use protective equipment where necessary.

• Only perform work on the motor during down-

time.

• Disconnect the motor from the compressed air

during all assembly and maintenance work.

• After completing all the work on the motor,

remount the safety devices in accordance with

specifications.

2.2 Proper use

A compressed air driven drum and container pump

comprises motor and pump tube to suit the particu-

lar application. Application of the compressed air

motors MD1xL and MD2xL in explosive hazard areas

or for pumping flammable liquids is only allowed

in combination with a pump tube approved for

category 1/2 G.

• Motor may only be operated with pump tube.

• The motor must not be immersed in the liquid

being pumped.

• The motor can be used in the following environ-

ment:

- temporarily outdoors without protection from

weather effects

- on roofed surfaces

- in open and closed rooms

- in explosive hazard areas

• Observe following technical data:

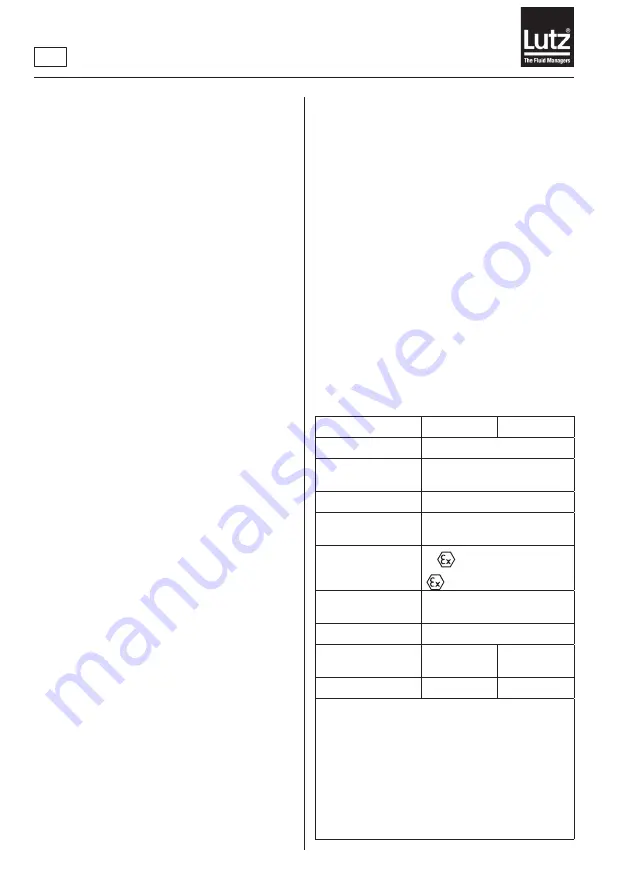

Type

MD1xL

MD2xL

Power output

1.34 hp / 1000 W

Max. operating

pressure

87 psi / 6 bar

4)

Air consumption

1)

53 SCFM / 1.5 Nm³/min

Ambient

temperature

-4°F up to 140°F /

-20°C up to +60°C

Marking

2)

II 2G Ex h IIB T6 Gb

II 2D Ex h IIIC T80°C Db

Sound pressure

level

3)

< 85 dB(A)

Sound power level

< 96 dB(A)

Weight

2.2 lb /

1.0 kg

3.0 lb /

1.4 kg

Order No.

0004-725

0004-735

1)

In standard condition (Characteristics of the air consump-

tion

→

Annex)

2)

Drum pumps are approved for explosion groups IIA and

IIB and temperature class T4. As a result hereof, the

combination motor/pump tube is also approved only for

matters (liquid to be pumped and/or environment) of this

classification.

3)

Measured at 87 psi (6 bar) operating pressure with fully

throttled pump tube

4)

72,5 psi (5 bar) for operation in hazardous areas or when

pumping flammable liquids.