Installation & Operation Manual

Please read before proceeding

Installer –

Read all instructions before

installing. Perform steps in the order given.

Have this storage tank serviced/inspected

by a qualified service technician, at least

annually.

Failure to comply with the above could result

in severe personal injury, death or substantial

property damage.

Failure to adhere to the guidelines on this

page can result in severe personal injury,

death, or substantial property damage.

When servicing the Strato-Therm+

–

• To avoid severe burns, allow the appliance to cool

before performing maintenance.

Appliance

operation –

• Do not use this appliance if any part has been under

water. The possible damage to a flooded appliance can

be extensive and present numerous safety hazards. Any

appliance that has been under water must be replaced.

When calling or writing about the appliance

– Please have the model and serial number

from the tank rating plate.

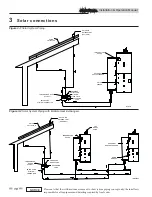

Consider piping and installation when

determining appliance location.

Any claims for damage or shortage in

shipment must be filed immediately

against the transportation company by the

consignee.

Factory warranty (shipped with appliance)

does not apply to appliances improperly

installed or improperly operated.

If the information in this manual is not

followed exactly, a fire or explosion may

result causing property damage, personal

injury or loss of life.

This appliance MUST NOT be installed in

any location where gasoline or flammable

vapors are likely to be present.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call

the fire department.

WARNING

NOTICE

WARNING

WARNING

3

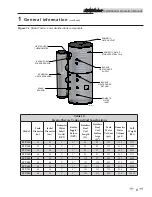

The following chart details the relationship of water temperature

and time with regard to scald injury and may be used as a

guide in determining the safest water temperature for your

applications.

APPROXIMATE TIME / TEMPERATURE

RELATIONSHIPS IN SCALDS

120°F

More than 5 minutes

125°F

1 1/2 to 2 minutes

130°F

About 30 seconds

135°F

About 10 seconds

140°F

Less than 5 seconds

145°F

Less than 3 seconds

150°F

About 1 1/2 seconds

155°F

About 1 second

• Installation and service must be performed by a

qualified installer, service agency, or the gas supplier.

Hot Water Can Scald!

•

Water heated to temperatures for clothes washing, dish washing, and other sanitizing needs can

scald and cause permanent injury.

•

Children, elderly, and infirm or physically handicapped persons are more likely to be

permanently injured by hot water. Never leave them unattended in a bathtub or shower.

Never allow small children to use a hot water tap or draw their own bath.

•

If anyone using hot water in the building fits the above description, or if state laws or local

codes require certain water temperatures at hot water taps, you must take special

precautions:

•

Use lowest possible temperature setting.

•

Install some type of tempering device, such as an automatic mixing

valve, at hot water tap or water heater. Automatic mixing valve must be selected and

installed according to valve manufacturer’s recommendations and instructions.

•

Water passing out of drain valves may be extremely hot. To avoid injury:

•

Make sure all connections are tight.

•

Direct water flow away from any person.

Protection Must Be Taken Against Excessive Temperature and Pressure!

--Installation of a Temperature & Pressure (T&P) relief valve is required.