22

6

Startup and maintenance

*

Ensure that the boiler and solar water piping are free of

leaks.

*

If there is an oil lubricated circulator in the system, make

sure it is lubricated as called for by the circulator

manufacturer.

*

Make sure that the heat source is maintained in accordance

with the manufacturer’s instructions.

*

If a water treatment system is required to keep the water

chemistry within the parameters shown in Table 2A (see

Section 2 - Pre-Installation), make sure that this system is

properly

maintained.

Annual service by a qualified service technician

should include the following:

Any procedure required by local codes.

Verify system pressure. Air venting procedure may require

adding water to bring boiler system up to pressure, typically

12 psig minimum.

Manually operate T&P relief valve at least once a year.

This will release some hot water.

WARNING

Before operating a T&P relief valve, make

sure no one is in front of or around the T&P

relief valve discharge piping. Hot discharge

water can cause severe personal injury or

substantial property damage.

DANGER

Plugging the T&P relief valve or discharge

piping can cause excessive pressure in the

water heater, resulting in severe personal

injury, death, or substantial property

damage.

Move operating lever to open position for a few seconds

and then move it back, allowing it to snap closed. After the

T&P relief valve is operated, if it continues to release water,

close the cold water inlet to the water heater immediately.

Follow the draining instructions, and replace the T&P

relief valve. If the T&P relief valve weeps periodically, it may

be due to thermal expansion. Do not plug the T&P relief

valve or discharge piping. In this case, ensure that the

expansion tank is properly sized and charged to the

appropriate

pressure.

Installation & Operation Manual

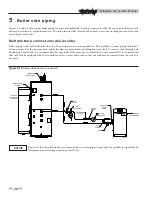

1. Make sure the system is free of leaks and that air is

purged from the system.

CAUTION

Fix any leaks found before proceeding

further. Leakage from the heat source and

solar piping can result in severe damage to

the system.

2. Many soldering fluxes contain Zinc Chloride which

can cause severe corrosion damage to stainless steel. After

completing all domestic water connections, flush the

Strato-Therm+ tank and indirect coil thoroughly before

leaving the installation. This is particularly important if the

Strato-Therm+ will be unused for an extended period of

time after installation. Flush the storage tank by drawing at

least three times its volume from the tank.

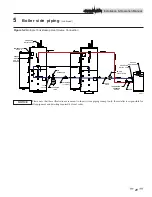

3. Make sure that each zone valve or circulator operates

when, and only when, its thermostat calls for heat. Let each

zone operate long enough to purge any remaining air from

the

system.

Refer to the heat source and solar Installation and Operation

Manuals for additional start-up information.

System startup

Maintenance Schedule

The Lochinvar Strato-Therm+ solar tank is an extremely simple

device and as such requires very little maintenance. There are,

however, several items which should be inspected on an annual

or as needed basis to ensure a reliable supply of hot water:

Verify that expansion tank pressure is equal to system

pressure.