20

5

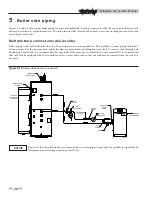

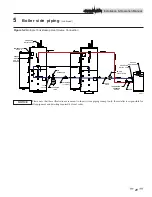

Boiler side piping

Installation & Operation Manual

Figures 5-1 and 5-2 show typical boiler piping for single and multi-tank situations. A pressure relief valve must be installed on each

boiler and each tank, as regulations require. The tank pressure relief valve should be sized to meet the working pressure of the tank

according to local codes.

Multiple tank connections (boiler side)

Boiler piping works most efficiently when it is done in the reverse-return application. This method uses more piping than direct

return systems, but the pressure drop and boiler flow are more balanced throughout each tank. To ensure even charging and

discharging of each tank, it is recommended that only tanks of the same size are placed in the same manifold. It is recommended

that each tank be equipped with its own isolation valves, unions and drains so that one tank may be removed from the system, if

necessary.

PRESSURE

RELIEF VALVE

TEMPERATURE

GAUGE

BACKUP

HEAT SOURCE

SENSOR

FILL

VALVE

AIR

SEPARATOR

Y-STRAINER

(TYPICAL)

CHECK

VALVE

BOILER

CIRCULATOR

PRESSURE

RELIEF

VALVE

T&P

GAUGE

DRAIN

BACKUP

HEAT SOURCE

IMG00086

Please note that these illustrations are meant to show system piping concept only, the installer is responsible for

all equipment and detailing required by local codes.

NOTICE

Figure 5-1 Backup Heat Source Connection