cont

ac

t-cooled dispensing s

ys

tem

17

NOTE:

If the defect persists even after the above steps are taken, contact a service centre.

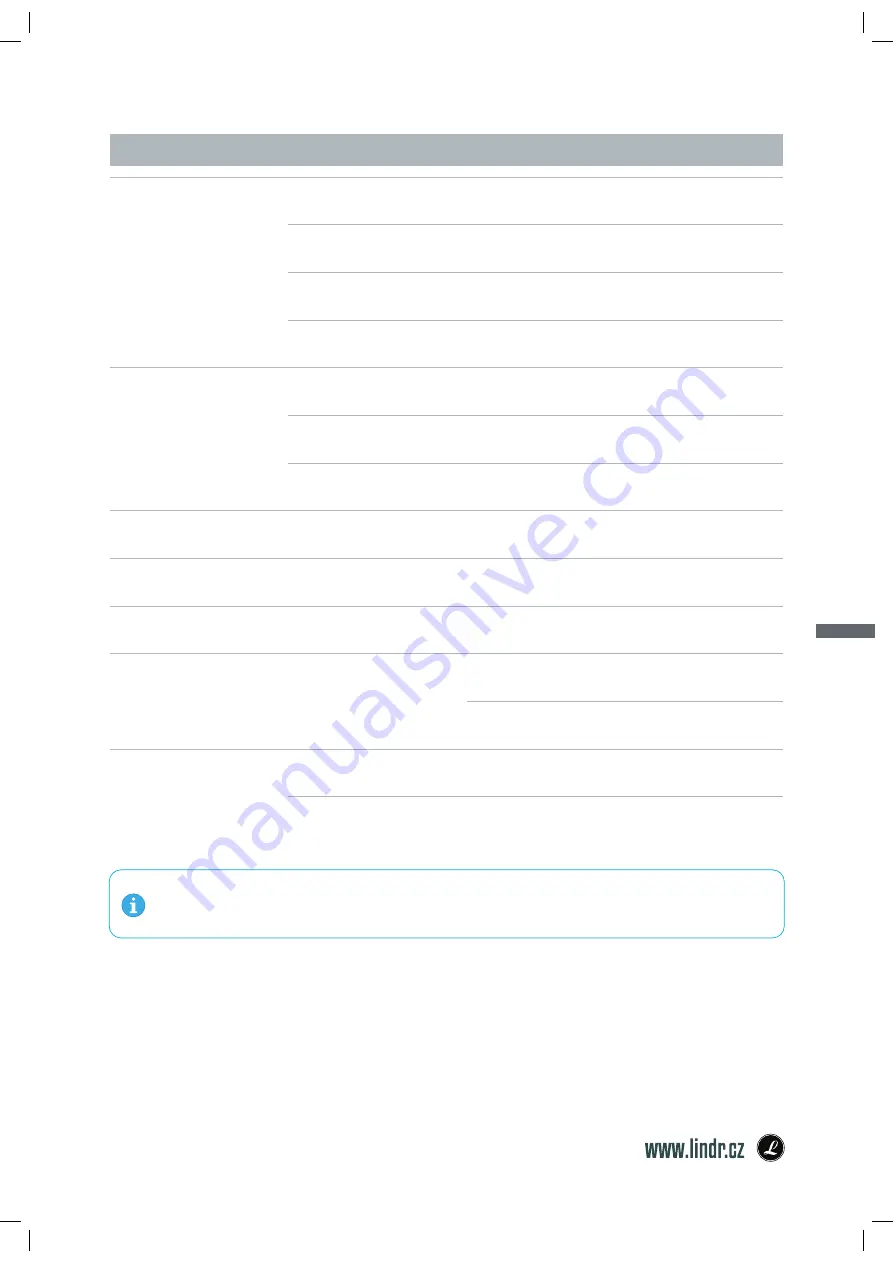

18. TABLE OF MALFUNCTIONS

Malfunction

Cause

Removal

beverage does not

fl

ow

keg tapped incorrectly

check that the keg coupler lever is pushed down

device with built-in compressor - turn on the switch

water from sanitation froze

turn o

ff

the device; then wait until the beverage starts

fl

owing again (may take a few minutes, or hours!)

compensator is closed

move the compensator lever on the tap

beverage cooled insu

ffi

-

ciently

incorrect thermostat setting turn the thermostat knob to the right towards

number 7

poor air circulation

check the cleanliness of condenser plates

device overheats

place the device in a colder environment

tap jerks, drink sprays out

pressure too high

reduce delivery medium supply, reduce pressure in

the keg

air compressor does not

switch on

press the switch on the cooler

air compressor does not

switch o

ff

leakage

pull out and reinsert the air hose, tighten the nuts

on the keg coupler

beer foams excessively

reduce beverage temperature - turn the thermostat

knob to the right

regulate

fl

ow rate by pushing the compensator lever

up

speed

fi

ttings leaking

hose poorly inserted

pull out the hose, check that the end of the hose is

fl

at (not at an angle), level o

ff

with a knife if needed

scratches on the hose

pull out the hose and shorten by ca. 2 cm

Do not forget to specify the following:

• type of defect

• product type

• production year

• product's serial number (found on the machine plate)