32

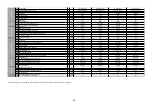

Declaration of vibration emission

Declared vibration emission values in compliance with EN 12096

Description

Value

European Norm (EN)

Test surface

Measured vibration emission value, a (m/s

2

)

0.97

EN ISO 20643 (Hand-Arm)

Industrial smooth concrete floor

Uncertainty, K (m/s

2

)

0.28

Measured vibration emission value, a (m/s

2

)

3.83

EN ISO 20643 (Hand-Arm)

On test track according to EN 13059

Uncertainty, K (m/s

2

)

0.15

Measured vibration emission value, a (m/s

2

)

0.77

EN 13059 (Whole body)

Industrial smooth concrete floor

Uncertainty, K (m/s

2

)

0.39

Measured vibration emission value, a (m/s

2

)

1.02

EN 13059 (Whole body)

On test track according to EN 13059

Uncertainty, K (m/s

2

)

0.08

Values determined in compliance with EN ISO 20643 and EN 13059.

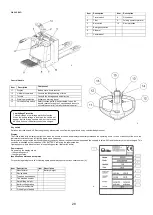

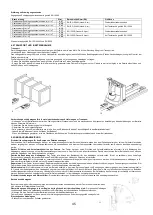

4.0 TRANSPORTATION AND COMMISSIONING

Transport

There are two way to pack the truck: one is to use a pallet, the other is use a box. The way to pick up depend on transport.

Only use crane handling equipment gear with enough capacity.

Loading weight must be more than net weight of truck (including battery weight for electric trucks) plus weight of the pallet or box

Pallet or box should be big enough and strong enough to bear whole truck.

– Park the truck securely (see Parking the truck securely).

– Make sure forks are positioned properly for the pallet. Move forward slowly to insert forks into the pallet as far as possible and then stop the truck.

Preparing the truck for first operation after delivery or transport:

– Only operate the truck with battery current. Rectified AC current will damage the electronic components. Cable connections to the battery must be less than 6 m.

– Check the equipment is complete.

– Check the hydraulic oil level.

– Install the battery if necessary (where required), (see "Battery removal and installation") do not damage battery cable.

– Charge the battery, (see "Charging the battery").

When the truck is parked the surface of the tyres will flatten. The flattening will disappear after a short period of operation.

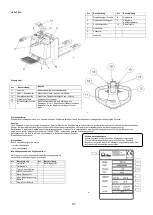

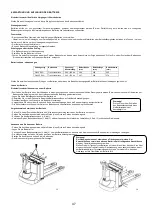

5.0 INSTRUCTIONS FOR USE

Safety Regulations for the Operation of pallet Trucks

Driver authorization: The pallet truck may only be used by suitably trained personnel, who have demonstrated to the proprietor or his representative that they can

drive and handle loads and have been authorized to operate the truck by the proprietor or his representative.

Driver’s rights, obligations and resp

onsibilities:

The driver must be informed of his duties and responsibilities and be instructed in the operation of the truck and

shall be familiar with the operator manual. The driver shall be afforded all due rights. Safety shoes must be worn with pedestrian operated trucks.

Unauthorized Use of Truck:

The driver is responsible for the truck during the time it is in use. He shall prevent unauthorised persons from driving or operating the

truck. It is forbidden to carry passengers or lift personnel.

Damage and Faults:

the supervisor must be immediately informed of any damage or faults to the pallet

truck. Trucks not safe for operation (e.g. wheel or brake problems) must not be used until they have

been repaired

Repairs:

The driver must not carry out any repairs or alterations to the pallet truck without the necessary

training and authorisation to do so. The driver must never disable or adjust safety mechanisms or

switches.

Hazardous area:

A hazardous area is defined as the area in which a person is at risk due to truck

movement, lifting operations, the load handler (e.g. forks or attachments) or the load itself. This also

includes areas which can be reached by falling loads or owering operating equipment. Unauthorized

persons must be kept away from the hazardous area. Where there is danger to personnel, a warning

must be sounded with sufficient notice. If unauthorized personnel are still within the hazardous area the

truck shall be brought to a halt immediately.

Safety Devices and Warning Signs:

Safety devices, warning signs and warning instructions shall be

strictly observed.

Operating the truck

Before the truck can be commissioned, operated or a load unit lifted, the driver must ensure that there is

nobody within the hazardous area.

Checks and operations to be performed before starting daily work

– Visually inspect the entire truck (in particular wheels and load handler) for obvious damage.

– Visually inspect the battery attachment and cable connections.

Do not drive the truck unless the panels are closed and properly locked.

Warning!

– To avoid break the fork be hurt when you move the

truck to stock.

– In order to keep the truck out of be scraped, please

move the truck void in void and flat place.

– when you lower the stock advert status of the place to

avoid collapse.

9

10

11

Содержание QX 20 EVO

Страница 1: ......

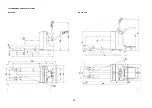

Страница 6: ...4 3 0 DIMENSIONI E SPECIFICHE QX 20 EVO QX 20P EVO 7 8...

Страница 19: ...17 3 0 DIMENSIONS ET SP CIFICATIONS QX 20 EVO QX 20P EVO 7 8...

Страница 32: ...30 3 0 DIMENSIONS AND SPECIFICATIONS QX 20 EVO QX 20P EVO 7 8...

Страница 45: ...43 3 0 ABMESSUNGEN UND SPEZIFIKATIONEN QX 20 EVO QX 20P EVO 7 8...

Страница 58: ...56 3 0 DIMENSIONES Y ESPECIFICACIONES QX 20 EVO QX 20P EVO 7 8...

Страница 72: ...70 3 0 DIMENS ES E ESPECIFICA ES QX 20 EVO QX 20P EVO 7 8...

Страница 85: ...83 3 0 AFMETINGEN EN SPECIFICATIES QX 20 EVO QX 20P EVO 7 8...

Страница 98: ...96 3 0 WYMIARY I SPECYFIKACJE QX 20 EVO QX 20P EVO 7 8...

Страница 111: ...109 3 0 DIMENSIUNI I SPECIFICA II QX 20 EVO QX 20P EVO 7 8...

Страница 122: ...120...

Страница 124: ...122...

Страница 125: ......