7

Installation

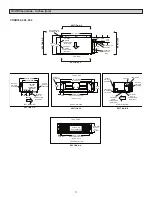

It is important to locate the unit where it can be accessed

for service in the future. Refer to unit dimensions on Pages

3-5 for exact locations of suspension brackets, return air

and supply air openings.

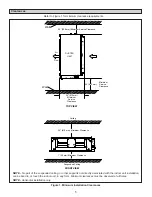

1. Make sure that the structural ceiling or slab is able

to support the weight of the indoor unit. It may be

necessary to add extra support.

2. Install suspension rods in the structural

ceiling or concrete slab in a suitable location.

If the structural ceiling is constructed of concrete,

install anchors to accept four ⅜” threaded rods to

suspend the indoor unit. If the structural ceiling

includes wooden joists, use angle iron or Unistrut

channel fixed securely in place to accept the ⅜”

threaded rods.

NOTE -

Threaded rod (requirement

of Lennox warranty program) is the ONLY acceptable

method of suspending the unit; do not use chains or

straps.

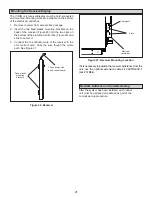

See Figure 2.

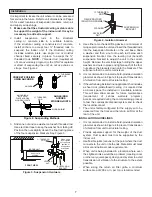

3. Slide one nut and one washer onto each threaded rod.

Use electrical tape to keep the washer from failing off.

Position the nuts slightly above the final resting place

of the four suspension brackets. See Figure 3.

Figure 2. Suspending Methods

ANGLE IRON

BOLTED IN

PLACE ACROSS

WOODEN JOISTS

WOODEN JOIST

⅜” THREADE

D

ROD

ANGLE IRON

ACROSS

WOODEN JOISTS

ANCHOR

CONCRETE CEILING

USING ANCHORS

⅜” THREADE

D

ROD

4. Use either a mechanical lifting device or a minimum of

two people to raise the unit and insert the threaded rods

into the suspension brackets on the unit base. Slide

a washer and then a nut onto each rod below each

suspension bracket. Use the leveling nut (beneath

suspension bracket) to adjust the unit to the correct

height. Remove the electrical tape holding the upper

washers and nuts in place and tighten each of the four

nuts above the brackets down onto the brackets. This

will ensure that the unit remains level.

5.

It is recommended to install a field-provided isolation

grommet as shown in Figure 4 to prevent transmission

of vibration from unit to structural ceiling.

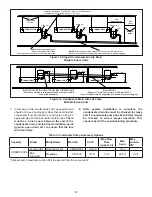

6. If the unit is being installed in an application that includes

a sheet rock (plasterboard) ceiling, it is required that

an access panel be installed in a suitable location.

This will also allow access for future maintenance

(requirement of Lennox warranty program).

Access is required during the commissioning process

to test the condensate disposal system and to check

the local disconnect.

7.

The unit is factory-configured for the supply air to be

delivered from the front and the return air filter at the

rear of the unit.

INSTALLATION GUIDELINES

•

It is recommended to install a field-provided isolation

grommet as shown in Figure 4 to prevent transmission

of vibration from unit to structural ceiling.

• Provide separate support for the weight of the duct

system. Duct system must not be supported by the

indoor unit.

•

Use flexible joints (canvas) at the point where the duct

connects to the unit on both ends. Material must meet

all local and national code requirements.

• When unit is being installed in a location where even

the slightest noise would be a problem (meeting room

or other very quiet space), design duct system to avoid

transmission of vibration to the structure to the extent

possible.

•

When sizing the return air filter grille, a minimum

surface area of 200 sq. in. per ton is recommended.

LEVELING

NUT

⅜

” THREADED

ROD

SUSPENSION

BRACKET

FIELD-PROVIDED

ISOLATION GROMMET

WASHER

INDOOR UNIT

LEVELING

NUT

⅜

” THREADED

ROD

SUSPENSION

BRACKET

SUPPLY AIR

OPENING

FRONT VIEW

When unit is

level, tighten

nut to secure

position of

suspension

bracket on

rod.

Figure 3. Suspension Hardware

Figure 4. Isolation Grommet