2

Model Number Identification

Safety Requirements

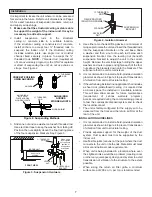

ELECTRICAL SHOCK, FIRE, OR EXPLOSION HAZARD.

Do not touch the unit or the controller if your hands are wet.

DO NOT spray water on the indoor unit for any reason.

Do not replace a fuse with a fuse of a different rating. Do not use a jumper wire to replace a fuse. Do not insert

your hands, tools or any other item into the air intake or air outlet at either the indoor or outdoor unit.

Do not allow children to operate the system.

WARNING

!

V OS B 036

H

4 - 3 P

Brand/Family

V = Variable Refrigerant Flow (VRF)

Unit Type

OS = Outside Air Ducted Indoor Models

Major Design Sequence

B = 2nd Generation

Cooling Efficiency

H = High Efficiency

Refrigerant Type

4 = R-410A

Controls Protocol

3 = Phase 3

Voltage

P = 208/230V-1 phase-60hz

Nominal Cooling Capacity Btuh

036 = 36,000 Btuh

048 = 48,000 Btuh

054 = 54,000 Btuh

072 = 72,000 Btuh

096 = 96,000 Btuh

CAUTION

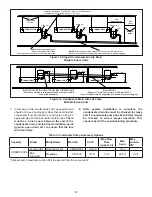

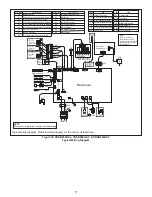

VRF system piping is customized for each installation.

The LVSS piping report is an engineered design that

must be followed. The piping diagram or diagrams

included within the LVSS report have been prepared

based on the information provided to the Lennox VRF

applications department.

When the indicated lengths change from the figures

stated within the report, it is imperative that prior to the

commencement of the refrigerant pipe work installation,

Lennox VRF applications department are informed of

these proposed changes.

Upon receipt of this new information the Lennox VRF

applications department will confirm any changes that

may be applicable to this installation. If changes are

required, a new piping diagram will be produced and will

supersede all other previously provided documents.

Failure to provide this information regarding changes

to the original design may lead to insufficient capacity,

equipment failure, warranty being made void and the

refusal to commission the system.

NOTICE

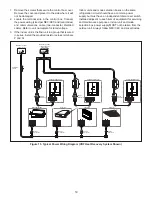

When using as part of a VRF Heat Recovery system,

refer to the specific pipe connection details located in

the Mode Selection Box installation manual and the

detailed drawing on page 16 of this manual.

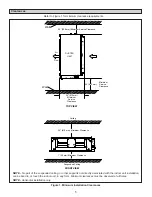

System Piping

NOTE -

Only Lennox VRF indoor units will work with Lennox VRF outdoor units and associated mechanical

equipment. Lennox Mini Split indoor units are similar in appearance but must not be connected to a Lennox VRF

refrigerant circuit. Please refer to model numbers to confirm compatibility. Model numbers for Lennox VRF units

start with a “V” and model numbers for Lennox Mini-Splits start with a “M”.