PROBLEM

CAUSE

SOLUTION___________________________

1. Insufficient purifier product

ion.

A. The test kit reagents or test strips are old or expired

D. Purifier loss due to intense sunlight exposure. D. Check the stabilizer level and add cyanuric acid if needed. (Refer

to the Cyanuric Acid Needed for 75 PPM section, page 6.) If

on bromine, replenish bromine residual.

2. Scale build-up within the cell.

C. Set the output control dial to 100 % and allow the filter pump to

operate 24 hours (were applicable remove the "OFF" tripper from

the external time clock) to super-chlorinate / brominate the water.

E. Repair the leak and rebalance the water being purified. (Refer to the

Pool Water Preparation section, page 5.)

input closest to wall.

A. The water being purified contains high pH,

A. Calculate Langelier's Index to assure balanced water. (See page 5)

alkalinity and calcium hardness.

Adjust the water chemistry and mix 1 part muriatic acid to 4 parts water.

Pour this solution into the cell and allow it to clean the cell for no

longer than 15 minutes. Repeat if necessary. Drain and rinse with

fresh water and re - install. Dilute pool water with fresh water if

necessary.

3. DC plug and cell terminals burned.

A. The cell cord plug is not securely pushed onto the cell A.

Ensure that the cell cord plug is pressed completely on the cell

terminals.

allowing moisture to seep into the plug. Check the cell terminals and clean with a dry cloth to remove all dirt and corrosion.

14

B. The unit is not reversing polarity B. Return the control panel testing/servicing

C. Possible cell failure

. C. Refer to #4 of this section. Return the cell for

F. Low salt.

.

necessary. (Refer to the Salt

B. The cell terminals leak. B. Shut off the main filter pump and patch the cell terminal(s) with epoxy putty

and leave the filter pump off for 24 hours.

C. Completely failed cell

C. Replace the cell.

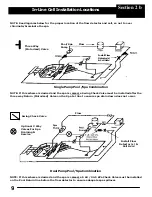

1) Disconnect AC power (unplug the control panel) and let sit for one (1) minute.

2) Set the percentage feed rate dial to 100%.

4) Control panel will start its self-test mode (Green/Red, Green/Red flashing lights) and run for approximately two (2) minutes.

NOTE: TROUBLE SHOOTING PROCEDURE

This procedure applies to all units manufactured after January 1, 2002

3) Reconnect AC power (plug in the control panel).

5) Control panel will then advance to cell test mode (Green flash).

6) It will then alternate between the Green flash and the specific "fault" flash [one (1) OR two (2) OR three (3) OR four (4) red flashes]

which indicates the source of the problem, as indicated below.

After the control panel has completed its diagostics and "timed out' on its internal clock, it will automatically go into the four (4) Red Flash mode,

regardless of the original fault. THE ABOVE PROCEDURES MUST BE PERFOREMED IN ORDER TO DETERMINE THE ORIGINAL FAULT.

B. The unit is set too low in relation to an increased purifier demand.

C. The bather load has increased.

E. The body of water being purified leaks.

B. Turn up the output dial and/or increase the filter pump run time.

A. Retest with new reagents or test strips.

F. Check the residual salt level and add if necessary. (Refer to

the salt Requirements Needed for 3000 ppm section, page 6)

G. Flow cable plugged into wrong input.

G. Unplug cable from front input and plug into back

testing/servicing if required.

4. Premature cell failure. (Requires replacement cell. Normal cell life, if sized and operated correctly, is 3 - 5 years.)

B. Debris in Cell B. Inspect cell monthly and clean

debris if required.

A. Abnormally high cell usage due to an insufficient cyanuric acid level.

A. Check the stabilizer level and a dd cyanuric acid if

needed. (Refer to the Cyanuric Acid Needed for 75PPM

section, page 6.)

Содержание 27315

Страница 19: ......