- -

17

10

Spare parts

10 Spare parts

UC-140 Indigo 50Hz UC-140 Indigo 60Hz

Amount

Article number

Article number

Compressor

1 0100165000 0104710000

Condenser

1 E3751054 E3751054

Evaporator

1 E5293018 E5293018

Motor fan

1 E5204252 E5204258S

Pump

1 E4521374 E4521442

Water tank

1 E3540026 E3540026

Liquid vessel

1 C210129000 C210129000

Expansion valve

1 0101807000 0101807000

Dryer filter

1 0112095000 0112095000

High pressure safety switch

1 0106437000 0106437000

Low pressure safety switch

1 0110140000 0110140000

Control thermostat

1 E5326003 E5326003

Antifreeze thermostat

1 E5326003 E5326003

Sight glass

1 0107397000 0107397000

Refrigerant gas kg (lb)

14 (31)

R-134a

R-134a

Level control

1 E4202004 E4202004

Water by-pass

1 E2301002 E2301002

Pump pressure gauge

1 E5544014 E5544022

Compressor contactor

1 E424202

2

S E4242024S

Pump contactor

1 E4251402S E4251402S

Motor fan contactor

1 E4251402S E4251402S

Pump's circuit breaker

1 E4266034 E4266038

Motor fan's fuse carrier

1 E4221420 E4221418

General switch

1 E4292012 E4292016

On/Off switch

1 E4132102 E4132102

2A Fuse

2 E4221231B E4221231B

6A Fuse

1 E4221232 E4221232

Motor fan fuses

3 E4221232 E4221242

Control transformer

1

E4181904S2

E4181930

Pressure transducer

1 E5328008T E5328008T

Speed regulator controller

1 E5328006 E5328006

Speed regulator

1 E5328004 E5323022

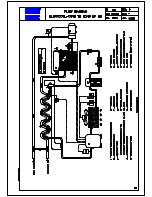

UC-140

IN

D

IGO

50

/60Hz 2

2

.0

4

.0

3 re

v.

1

Содержание Ultracool Superplus series

Страница 1: ...OPERATION MANUAL ultracool mini 0140 Indigo Ref MI 080 Rev 1 Date 30 04 03 50 60 Hz...

Страница 16: ...15 8 Log Book 8 Log Book 8 1 Log Book Date Remarks Signature UC 140 INDIGO 50 60Hz 29 01 03 rev 0...

Страница 19: ......

Страница 20: ......

Страница 21: ......

Страница 22: ......

Страница 23: ......