Page A - 60

A

LW SC-300 E / LW SC-350 E

Version: 06.12.2022

M A I N T E N A N C E A N D S E R V I C E

Safety valves

Every pressure stage is equipped with a separate over

pressure safety valve. Safety Valves avoid a non permissible

high pressure at the specific pressure stages and limit

maximum operation pressure of the compressor.

Safety valves are adjusted to:

• 1st Stage: 8 bar

• 2nd Stage: 60 bar

• 3rd Stage: max. final pressure

The adjusted blow-off pressure [bar] of the safety valves is

indicated on their housings.

All safety valves are factory sealed with special L&W safety

seals to avoid manipulation of the limit value settings.

Safety valves with removed seals have to be immediately

checked for the prescribed settings and replaced if necessary.

The safety valve of the final stage is furthermore equipped

with a knurled screw to be activated once.

Turning the knurled screw clockwise could vent the valve

completely and therefore the final filter housing.

During normal operation conditions, the knurled screw has to

be turned anti-clockwise up to the upper stop. An integrated

circlip avoids complete unscrewing.

If a safety valve blows off, it indicates problems with either

inlet or outlet valve of the following stage.

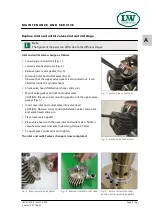

Safety valve 1st stage

Safety valve 2nd stage

Safety valve 3rd stage

Note

Replace defective safety valves immediately!

i

Содержание SC-300 E

Страница 3: ...A Operating Instructions Breathing Air Compressor LW SC 300 E LW SC 350 E Version 12 22 E...

Страница 12: ...A S A F E T Y P R E C A U T I O N S...

Страница 19: ...A I N S TA L L AT I O N...

Страница 21: ...Page A 19 A LW SC 300 E LW SC 350 E Version 06 12 2022 I N S T A L L A T I O N Dimensions Fig Dimensions...

Страница 26: ...A O P E R AT I O N...

Страница 34: ...A R E M E D Y I N G FA U LT S...

Страница 39: ...A M A I N T E N A N C E A N D S E R V I C E...

Страница 67: ...A M A I N T E N A N C E R E C O R D S...

Страница 75: ...E A T T A C H M E N T Version 11 12 E...

Страница 79: ...INFORMATIONON THE SERVICE LIFE OF L W HIGH PRESSURE HOSES...

Страница 87: ...ANNEX...