4-8 BRAKE SYSTEM MAINTENANCE

WARNING

1. WHEN CRAWLING UNDER THE

SEMITRAILER IS NECESSARY,

CHOCK ALL WHEELS OF THE

TRAILER AND TRACTOR. WHEN

JACKING IS NECESSARY, CHOCK ALL

WHEELS AND SUPPORT THE SEMI-

TRAILER UNDERCARRIAGE WITH

JACK STANDS SUFFICIENT TO WITH-

STAND THE WEIGHT OF THE SEMI-

TRAILER AND LOAD. FAILURE TO

TAKE ADEQUATE SAFETY MEAS-

URES MAY RESULT IN SERIOUS PER-

SONAL INJURY OR DEATH.

2. USE GREAT CARE IF WHEELS OR

BRAKE DRUMS MUST BE HANDLED.

THEY MAY BE VERY HOT AND CAN

CAUSE SERIOUS BURNS.

4-8.1

General

A daily general inspection will reveal the most

common problems found in the spring brake sys-

tem. This inspection should include the following:

a.

Check air hoses for chafing, bends, kinks,

or damaged fittings. Replace defective hoses.

b.

Check the brake system for loose, missing,

deformed, or corroded fasteners. Replace

and tighten defective hardware.

c.

Check brake linings for excessive wear or

distortion.

d.

Drain air reservoir daily. A drain cock on the

bottom of each air reservoir vents the tank to

drain collected water and oil. If held open, air

pressure in the tanks is relieved, causing the

emergency or parking brakes to be applied

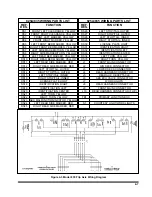

(See Figure 4-10).

4-8.2

Spring Air Brake Chambers

Check for faulty units. Check the condensation

holes on the underside of the brake chambers to

make sure they are open. The spring brake has

two brake chambers, a service chamber and an

emergency chamber or spring chamber. Service

brake chambers should be disassembled and

cleaned at 50,000 miles or yearly. The diaphragm

and any marginal parts should be replaced. When

replacing the service diaphragm, replace the corre-

sponding parts for the other chamber on the same

axle (to aid in even brake application and release).

Examine yoke pin for wear and replace as neces-

sary. The spring chamber should not be serviced.

Replace entire unit (both service and spring cham-

ber) if spring chamber becomes faulty.

WARNING

THE SPRING BRAKE CHAMBER EM-

PLOYS A SPRING WITH HIGH

FORCES. SERVICE SHOULD NOT BE

ATTEMPTED. SERIOUS INJURY OR

DEATH MAY RESULT.

4-15

Figure 4-10 Drain Cock Locations

Содержание 825A

Страница 3: ...MODEL 825A 835 DETACHABLE TRAILER OPERATOR S MANUAL PURCHASED FROM DATE ADDRESS PHONE NO SERIAL NO i...

Страница 8: ......

Страница 12: ......

Страница 14: ...3 2 Figure 3 1 Model 825 Trailer Terminology Figure 3 2 Service Hookups...

Страница 18: ...3 6 Figure 3 3 Hydraulic Controls...

Страница 22: ...3 10 Figure 3 5 Swingout Outrigger Platform Extension...

Страница 24: ...3 12 Figure 3 6 Gooseneck Attachment to Frame...

Страница 34: ......

Страница 36: ...4 2 Figure 4 1 Lubrication Points...

Страница 40: ...4 6 Figure 4 2 Model 825A Wiring Diagram...

Страница 43: ...4 9 Figure 4 4 Tandem Axle Air Ride Suspension System...

Страница 44: ...4 10 Figure 4 5 Tandem Axle W Flip Air Ride Suspension System...

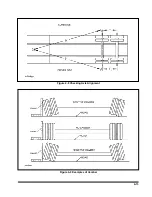

Страница 47: ...4 13 Figure 4 8 Checking Axle Alignment Figure 4 9 Examples of Camber...

Страница 52: ...4 18 Figure 4 12 Axle and Brake Assembly...

Страница 59: ...4 25 Figure 4 18 Mounting Tires and Wheels Figure 4 19 Stud Tightening Sequence...

Страница 69: ...NOTES 5 9...

Страница 70: ......