-5-

www.igmtools.com

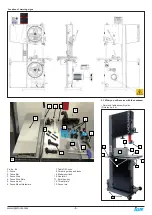

19. Guards

When running, the blade can be very dangerous,

and the amount of blade that is exposed must be

kept to a minimum. The machine is supplied with a

number of guards, all of which

MUST

be installed

and used while the machine is running. There is

a guard that is attached to the lower door and is

adjustable vertically once the door is closed. There

is a guard on the guide vertical adjustment shaft.

20. Blade tilt and tension mechanism

The upper wheel is attached to the tilt and tension

mechanism. This mechanism adjusts the wheel so

that the bandsaw blade can be adjusted for blade

tracking. This is achieved by a screwed handle

at the back of the machine that pushes on the

mechanism and adjusts the axis of the wheel so

that it runs true with the lower wheel. The second

function is to tension the blade, which is achieved

by adjusting the upper flywheel vertically. A handle

is located below upper flywheel and, when rotated,

will move the wheel up or down. The machine

has a quick-acting blade release mechanism that

is located at the back of the machine and will

remove the tension from the blade to speed the

removal and fitting of blades. The mechanism has

a spring, which helps to keep the tension constant

as the blade expands and contracts with the heat

generated by the cutting action.

21. Electrical connection

The bandsaw is provided with a cable.

22. Identification

There is a plate at the back of the

machine listing all the

manufacturing data.

3.2 Specification

Motor voltage

400V, 2,2 kW, 50Hz, 3 Ph

Breaker

3 x 16 A,

tripping characteristic C (16/3/C)

Throat

463 mm

Table cast iron

508 mm x 660 mm

Table tilt

- 6° + 45°

Mitre slot

9,5 mm x 19 mm

Table height

965 mm

Fly wheel

Cast iron

Resaw capacity

406 mm

Minimum blade length

3651 mm

Maximum blade length

31,75 mm

Minimum blade width

3 mm

Guides Ceramic

Height

1 975 mm

Machine dimensions (W x D) 919 x 759 mm

Base footprint

688 x 500 mm

Machine dimensions with mobility kit (W x D)

1093 x 797 mm

Base footprint with mobility kit

949 x 618 mm

Weight gross

200 kg

Weight net

186 kg

Package size W x D x H

2070 x 860 x 615 mm

Mobility kit

Optional

Industrial work-light

Optional

Fence Face Dimensions

18,5 x 57,5 cm

3.3 Noise emission

Equivalent A-weighted Sound pressure level

according to EN ISO 3746: 73.56 dB(A)

Uncertainty, K in decibels: 4.0 dB (A) according to

EN ISO 4871 The figure quoted is emission levels

and are not necessarily safe working levels. Whilst

there is a correlation between the emission and

exposure levels, this cannot be used reliably to

determine whether or not further precautions are

required. Factors that influence the actual level of

exposure of the workforce include characteristics

of the work room, the other sources of noise, etc.

Like the number of machines and other adjacent

processes.

4. General safety

Warning: Read all safety considerations. Failure

to follow this set of guidelines can result in

unwarranted damage to the machine and serious

injury to the operator and bystanders. Save all

warnings and instructions for future reference.

4.1 Safety instructions

• Keep guards in place and in working order.

• Remove adjusting keys and wrenches. Form

habit of checking to see that keys and adjusting

wrenches are removed from tool before turning it

on.

• Keep work area clean. Cluttered areas and

benches invite accidents.

• Don’t use in dangerous environment. Don’t use

power tools in damp or wet locations, or expose

them to rain. Keep work area well lighted.

• Keep children away. Ali visitors should be kept

safe distance from work area.

• Make workshop kid proof with padlocks, master

switches or by removing starter keys.

• Don’t force tool. It will do the job better and safer

at the rate for which it was designed.

• Use right tool. Don ‘t farce tool or attachment to

do a job for which it was not designed.

• Use proper extension cord. Make sure your

extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough

to carry the current your product will draw. An

undersized cord will cause a drop in line voltage,

resulting in loss of power and overheating. Table a

shows the correct size to use depending on cord

length and nameplate ampere rating. If in doubt,

use the next heavier gage. The smaller the gage

number, the heavier the cord.

• Wear proper apparel. Do not wear loose clothing,

gloves, neckties, rings, bracelets or other jewelry

that may get caught in moving parts. Nonslip

footwear is recommended. Wear protective hair

covering to contain long hair.

• Always use safety glasses. Also use face or

dust mask if cutting operation is dusty. Everyday

eyeglasses only have impact-resistant lenses; they

are not safety glasses.

• Secure work. Use clamps or a vise to hold work

when practical. Lt’s safer than using your hand,

and it frees both hands to operate tool.

• Don’t overreach. Keep proper footing and

balance at all times.

• Maintain tools with care. Keep tools sharp

and clean for best and safest performance.

Follow instructions for lubricating and changing

accessories.

• Disconnect tools before servicing, when changing

accessories such as blades, bits and cutters.

• Reduce the risk of unintentional starting.

Make sure switch is in off position before plugging

in.

• Use recommended accessories. Consult the

owner’s manual for recommended accessories.

The use of improper accessories may cause risk of

injury to persons.

• Never stand on tool serious injury could

occur if the tool is tipped or if the cutting tool is

unintentionally contacted.

• Check damaged parts. Before further use of

the tool, a guard or other part that is damaged

should be carefully checked to determine that it will

operate properly and perform its intended function

- check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting and

any other conditions that may affect its operation.

A guard or other part that is damaged should be

properly repaired or replaced.

• Direction of feed. Feed work into a blade or cutter

against the direction of rotation of the blade or

cutter only.

• Never leave tool running unattended turn power

off. Don’t leave tool until it comes to a complete

stop.

Location of warning signs

Because the direction of the blade is always

downward toward the table, there is little danger

(except for special cuts) that the wood will be

thrown back at the operator, which is called a

kickback. There is always danger of kickback when

a circular saw is being used. For safety reasons

many woodworkers prefer the bandsaw especially

when cutting small pieces. The unique feature of

the bandsaw is that the work piece can be rotated

around the blade creating a curve. It is the tool

most often used when curves have to be cut in

wood. Because the bandsaw blade is fairly thin, it

can cut thick stock with a minimum of horsepower.

For this reason the bandsaw is often used when

valuable pieces of wood are made into a thin piece

of veneer.

5. Unpacking your machine

5.1 Transport and unpacking

It is probable that your machine will be delivered

by a third party. Before you unpack your new

machine, you will need to first inspect the packing,

invoice and shipping documents supplied by the

driver.

Ensure that there is no visible damage to the

packing or the machine. You need to do this prior

to the driver leaving. All damage must be noted on

the delivery documents and signed by you and the

delivery driver. You must then contact the seller

within 24 hours.

5.2 Unpacking

To unpack your machine, you will need tin snips,

knife and a wrench.

Note

: The machine is heavy, and if you have

any doubt about the described procedure, seek

professional assistance. Do not attempt any

procedure that you feel is unsafe or that you do not

have the physical capability of achieving.

Using the tin snips, cut the banding that is securing

the machine to the pallet (if fitted).

WARNING: EXTREME CAUTION MUST BE

USED BECAUSE THE BANDING WILL SPRING

AND COULD CAUSE INJURY.

Your bandsaw will be shipped in custom packaging

consisting of a heavy-duty cardboard box and

Styrofoam internal packaging.

1. Open the cardboard box and remove the loose

parts and top Styrofoam.

2. Lift the bandsaw out of the packaging. You

will need two or more people, as the bandsaw is

heavy.

3. Lift the bottom Styrofoam out and remove the

parts that are packaged under the

bandsaw and packaging.