-11-

www.igmtools.com

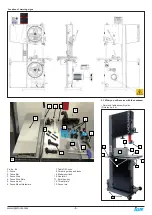

7.5 Adjusting the blade guards

Welcome to a new era in bandsawing. You

have purchased a bandsaw with a revolutionary

blade guide system that is designed to give you

years of safe, high-quality bandsawing. Most

blade guides are designed to support the blade

on the sides and either above or below the

side guides at the back of the blade. This can

allow the blade to twist as pressure from the

wood being cut pushes against the back blade

guide. The Laguna Guide eliminates this by

supporting the blade above and below the back

blade guide, giving the blade unsurpassed

stability. The Laguna Guide also incorporates

patented ceramic as the blade support material.

The advantage of this material is its ability to

resist wear, and with care it should give years

of safe service.

Please read the following notes as they

will assist you in getting the optimum

performance from your Laguna guide

system.

As with the roller guide systems, the Laguna

guide system will damage your blade if it is not

adjusted correctly. The guide blocks must not

come in contact with the teeth of the blade. It is

advisable to run the blade by hand with the

guide blocks completely clear of the blade, and

only when you are completely sure that the

blade is running consistently in the correct

position, you may then adjust the surround

guide blocks as detailed in this manual.

Note on using the Laguna ceramic guide

system.

1.

When fitting a blade to your bandsaw, adjust

the guide blocks as detailed later and run the

blade by hand through the guide blocks for at

least two complete revolutions.

2.

The weld on a new blade may not be

perfectly aligned, and the misalignment could

hit the ceramic blocks (side and back), causing

damage to the blocks or the blade. If the blade

has a bad weld, return it to your blade supplier

or side dress and file the back of the blade as

needed.

3.

The back blade guide is manufactured from

ceramic, so as the blade pushes against it,

friction between the blade and the ceramic

occurs. This action generates a certain amount

of sparks. This is normal and will become

less with time as the back of the blade guide

smoothes out the back of the blade.

4.

The back blade guide will slowly form a small

grove as the blade is used (this is normal). It

is recommended that for approximately every 8

hours of use, the guide be rotated 15 degrees.

This will ensure that the groove does not

become too deep and will greatly extend

the life of your guide.

5.

The Laguna guide system can be used with

1/8” to 1-1/4”blades.

6.

The Laguna guide system uses ceramic to

support and guide the blade. This has many

advantages (very poor conductor of heat, very

resistant to wear, etc.). The disadvantage is

that it is very brittle, so the guides must never

be dropped, exposed to hard knocks, hit with

hard objects or used with badly welded blades.

Any of the above actions may cause the

ceramic to chip or break and will detract from

the performance of the Laguna guide system.

Any mistreatment of the guide system will

render the warranty void.

7.

The side guide blocks must be tightened

before running the machine to avoid jamming

the blade and damaging the machine and/or

guide blocks.

8.

When cutting gummy or green wood, the

blade can become covered with resin. You will

find that the surround guide system ceramic

blocks remove the resin as the blade is moved

through the guide blocks and keep that

part of the blade clean. For this reason it is

recommended that the blocks be adjusted as

close to the gullet as possible, but the teeth

must not come in contact with the blocks, as

they will become damaged. Although the guide

blocks clean the blade, some woods will still

gum the blade and the resin will have to be

removed with solvent.

7.6 Adjusting the blade guides

The blade should run through the center of

the rear blade guide, and the side guides

should be parallel with the blade. If they have

been moved out of adjustment, adjust as

follows:

Top Upper Side Guides Parallel

Adjustment.

Loosen the side guides and move out as far as

possible. Loosen the guide assembly and move

back away from the blade. Move the back blade

guide forward so it just touches the back of the

blade and lock in position.

Loosen the guide clamp screw that allows the

side guides to move forward and back. Adjust

so that the ceramic blocks are just behind the

gullet of the teeth and are parallel to the blade.

Retighten the clamp screws. Gently push one

side guide so that it touches the blade and

lock it in position. Bring the other guide toward

the blade so that there is minimal clearance

between the blade and the guide. You can put

a thin piece of paper to put between the blade

and the guide to obtain the correct clearance

until you gain experience. Tighten the clamp

screws and remove the paper. Rotate the blade

by hand, ensuring that the weld of the blade

does not hit the ceramic blocks, as this will

cause damage. If the blade has a bad weld,

dress the blade or return it to your supplier.

Rotate the blade by hand and check that the

back of the blade does not hit the blade guide

with a bad weld. If the back of the blade hits the

back blade guide at the weld, then dress the

blade or, in excessive cases, return the blade to

the supplier.

Lower blade guide.

The lower blade guides have two locking

screws that, when released, allow the guide

assembly to be moved forward and back.

Rotate the blade by hand and ensure that it

is tracking consistently in the correct position.

Loosen the side guides and move out from the

blade. Loosen the two clamp screws that allow

the guide assembly to move forward and back.

Adjust it so that the ceramic blocks are just

behind the gullet of the blade and retighten the

clamp screws.

Place a dollar bill or piece of paper of similar

thickness between the guide blocks and the

blade. Gently bring both side guides toward the

blade so that slight pressure is exerted on the

blade. Tighten the clamp screws and remove

the paper. Rotate the blade by hand, ensuring

that the weld of the blade does not hit the

ceramic blocks, as this will cause damage. If

the blade has a bad weld, dress the blade or

return it to your supplier.

Loosen the rear guide clamp screw and push

the guide forward so that it just touches the

back of the blade.

Tighten the guide in position.

Rotate the blade by hand and check to see that

the back of the blade does not hit the blade

guide with a bad weld. If the back of the blade

hits the rear blade guide at the weld, then dress

the blade or, in excessive cases, return the

blade to the supplier.

Note:

You will probably find that the guides can

be adjusted more easily by tilting the table to 45

degrees.

Note:

Rotate the back guide by approximately

15 degrees after every 8 hours of use. This will

greatly extend the life of the back blade guide,

as it will even out the wear.

Before you cut any wood, read the safety

rules at the front of this manual.

Side guide clamp screw

Back guide clamp screw

Back guide touching the

back of the blade

Adjusted guide

Guide locking screws