Page 37

NOTE: Check for good quality pilot flame.

See Section 9.C on page 38.

NOTE: Check the flame current and make the

necessary adjustments to the pilot valve. See Section

9.C on page 38. Flame current should be set to a

minimum of 1.O micro amp.

7. When pilot flame is sensed, the main valve is energized.

NOTE: The limits, damper switch and pilot flame are

continuously monitored during main valve operation.

If any of these are opened or pilot flame is lost the

main valve is immediately de-energized. A blinking

green LED will indicate the cause of the shutdown

(limits, v-sw, or flame).

8. Observe the main flame pattern on all burners.

There should be minimal pulsing, unstable or lifting

flame patterns. For any abnormal flame, check gas

pressures and orifice alignment. If the gas pressures

and orifice alignments are good, then the air shutter

needs to be adjusted.

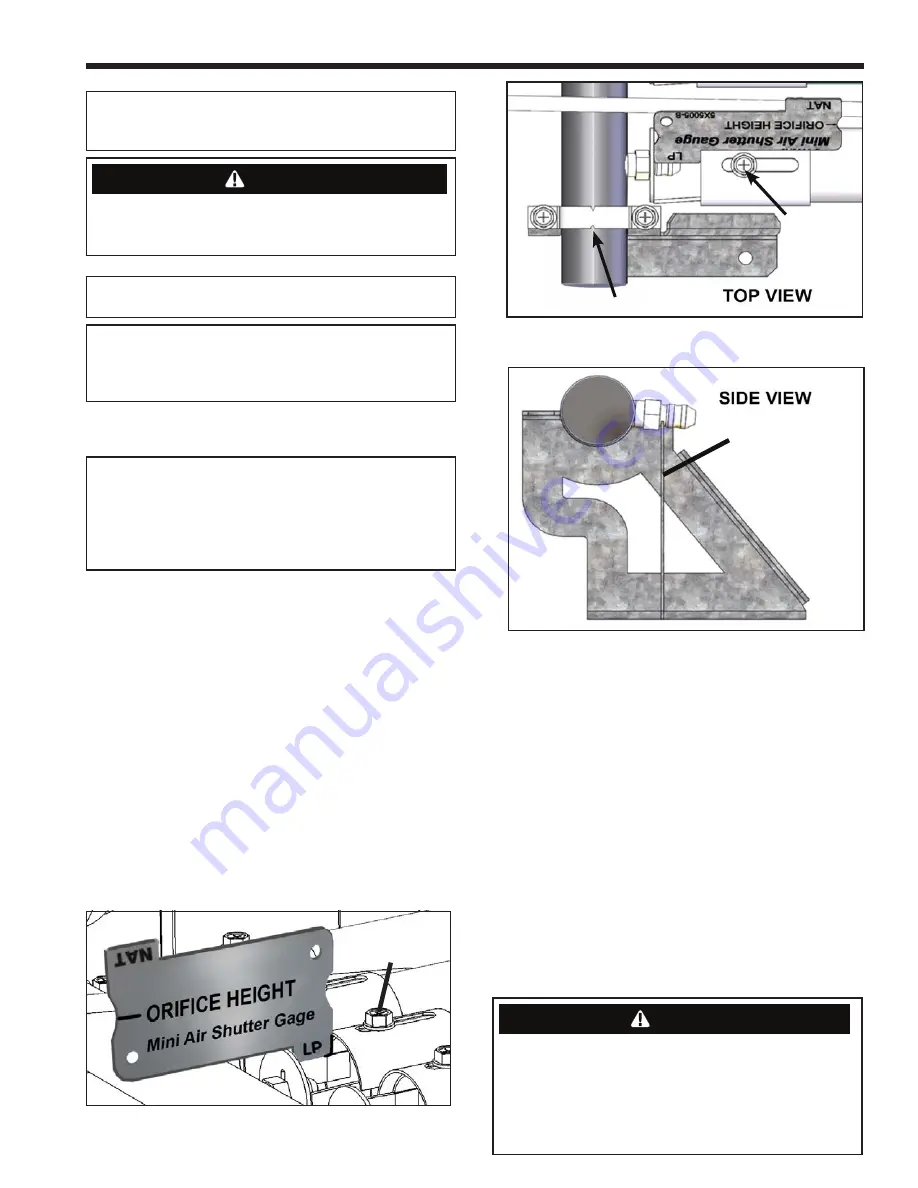

On all burners exhibiting an abnormal flame, use a

5/16 inch wrench to loosen (do not remove) the air

shutter locking screw. Slowly close or open the air

shutter until a normal flame is observed then re-

tighten its associated locking screw. If returning to

factory setting is desired, measure one of two ways.

1-Measure. Factory setting is .75” from shutter to

burner orifice mounting plate. 2-Use the Mini-Gauge

to set to factory starting point. See Figure 40 and

Figure 41.

9. After the startup, the ignition system safety device

must be tested. To test, close the manual gas valve

and verify that the burner flame is extinguished and

the boiler continues to try to restart (continuous retry

of pilot). You can then allow the boiler to restart by

opening the manual gas valve.

10. Allow the boiler to operate until the target

temperature or high temperature set point is

reached. The yellow TARGET LED or the yellow

HI-TEMP LED will light. The main burner and pilot

flame will turn off. The FLAME LED will turn off.

11. The damper will begin to close and the V-PWR,

V-SW and LIMITS LEDs will turn off.

12. Lower the room thermostat temperature to remove

the call for heat. The third decimal, lower right of

the control display will turn off

WARNING

Fire, explosion, or carbon monoxide hazard. Water

damage can lead to unreliable operation or cause

the control to malfunction which could lead to severe

personal injury or death. Do not install the control

module where it can get wet. Always replace the control

if it gets wet or if it has any signs of water residue.

Figure 39. The Mini-Gauge (included with the

installation kit) for Orifice Adjustment

Mini-Gauge

stands vertically

for Orifice Angle

Adjustment

Air shutter

locking screw

Air shutter

locking

screw

Align with Mark

Figure 40. The Mini-Gauge for Shutter Adjustment

Figure 41. The Mini-Gauge for Orifice Adjustment

NOTE Always test for a complete electrical system

ground. High voltage ignition can cause electrical

interference if not properly grounded.

WARNING

Electrical shock hazard. The ignition circuit of the

control can produce over 10,000 volts which can

cause severe injury or death.

M

INI-

T

HERM

JX

Residential Boilers

®