26

6.

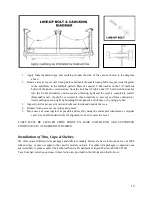

Suction and liquid lines should never be taped or soldered together. Adequate heat exchanger is

provided in the case. Kysor/Warren recommends use of heat exchanger in all medium and

low temperature cases that are not mechanically sub-cooled for proper operation.

7.

Refrigeration lines should never be placed in the ground unless they are protected against

moisture and electrolysis attack.

8.

Always slope suction lines down toward the compressor, 2" each 10’. Do not leave dips in the

line that could trap oil.

9.

Provide P traps at the bottom of suction line risers that are 4 feet or longer. Use a double P trap

for each 20 feet of risers. P traps should be the same size as the horizontal line. Consult the

technical manual or legend sheet for proper size risers.

10.

Use long radius ells and avoid 45 degree ells.

11.

Provide expansion loops in suction lines on systems on hot gas defrost. An expansion loop is

required for each 100’ of straight run.

12.

Strap and support tubing to prevent excessive line vibration and noise.

13.

Brazing of copper-to-copper should be with a minimum of 10% silver. Copper to brass or copper

to steel should be with 45% silver.

14.

Do not use bullhead tees in suction lines. Example: when suction gas enters both ends of the tee

and exits the center. This can cause a substantial increase in pressure drop in the suction lines.

15.

When connecting more than one suction line to a main trunk line, connect each branch with an

inverted trap.

16.

Suction Lines

a.

Should be pitched in the direction of flow.

b.

Should enter at the top of the branch line.

c.

May be reduced by one size at 1/3 of case run load and after 2/3 of case run load. DO

NOT reduce below the case suction line size.

Expansion Valve and Superheat

Expansion valves are supplied for the refrigerant specified on the original sales order.

CAUTION

: During service of this equipment, precautions should be taken to prevent loss of

refrigerant to the atmosphere. Always install the expansion valve stem cap after making valve

adjustments.

The expansion valve furnished with your case has been sized for maximum coil efficiency. To adjust

superheat, perform the following:

1.

Place a thermocouple near the expansion valve bulb. Read the suction line pressure as near coil as

possible. (If at the condensing case, estimate suction line loss at 2 PSIG).

2.

Convert coil suction pressure to temperature. The difference between coil temperature and the

thermocouple temperature is superheat. (Use average superheat when expansion valve is

hunting).

3.

Do not set Superheat until cases have been pulled down to operating temperature. Never open or

close the valve over ¼ turn between adjustments. Allow 10 minutes or more between

adjustments.

4.

Superheat should be set to 6-8°F.

5.

After the initial setting, the superheat should be rechecked when product is stocked and at desired

temperature.

Содержание QILG 06

Страница 2: ...2 ...

Страница 7: ...7 Plan View and Cross Sections QILG Cross Section ...

Страница 8: ...8 QILG Plan View ...

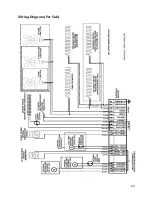

Страница 23: ...23 Wiring Diagram Per Side ...

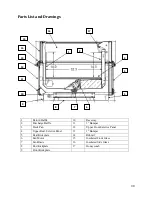

Страница 34: ...34 ...

Страница 35: ...35 ...