How to Enter Calibration Data

3-6

965X Operation Manual

How

to Enter Calibration Data

Adjustment menus are located in the setup screens. In these menus, you can add negative or posi

-

tive adjustments to move a servo to desired positions to compensate (calibrate) for any deviation’s

from the expected cut. The calibration can then be saved.

Note:

Maximum offset is 0.50 inches. If more than 0.50 inches of adjustment is

needed, there is a high probability that another issue may be causing a problem.

If issues can not be resolved, contact the

Kval Service Center

(1-800-553-5825).

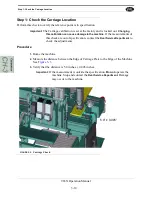

About The Calibration Box

Below are general instructions to perform a calibration.

1.

Check for deviations between the expected machining and the actual machining.

Determine the offset.

2.

Enter a positive or negative offset in the

Offset

box to adjust the servos in the X, Y,

and Z directions.

Note:

Select the

Combine Button

to keep track of the offsets during the process.

3.

After every calibration change, select the

Save

button to store the calibration. Run a

test jamb again to verify the offset correction was successful.

4.

Keep running a test jamb and adjusting the offset until satisfied with the result.

Total: Is the running

total of the Base and

the Offset

Combine: Merges the

offset number to the

base.

Base: Is the result of

the Combine selec

-

tion. (The merge of

the Offset and the

Base)

Offset: Enter the

desired offset to bring

into calibration.

Save Button: Select to store the calibration.

Содержание 965X

Страница 29: ...How to Download the Service Application 1 21 965X Operation Manual Page Intentionally Left Blank ...

Страница 103: ......