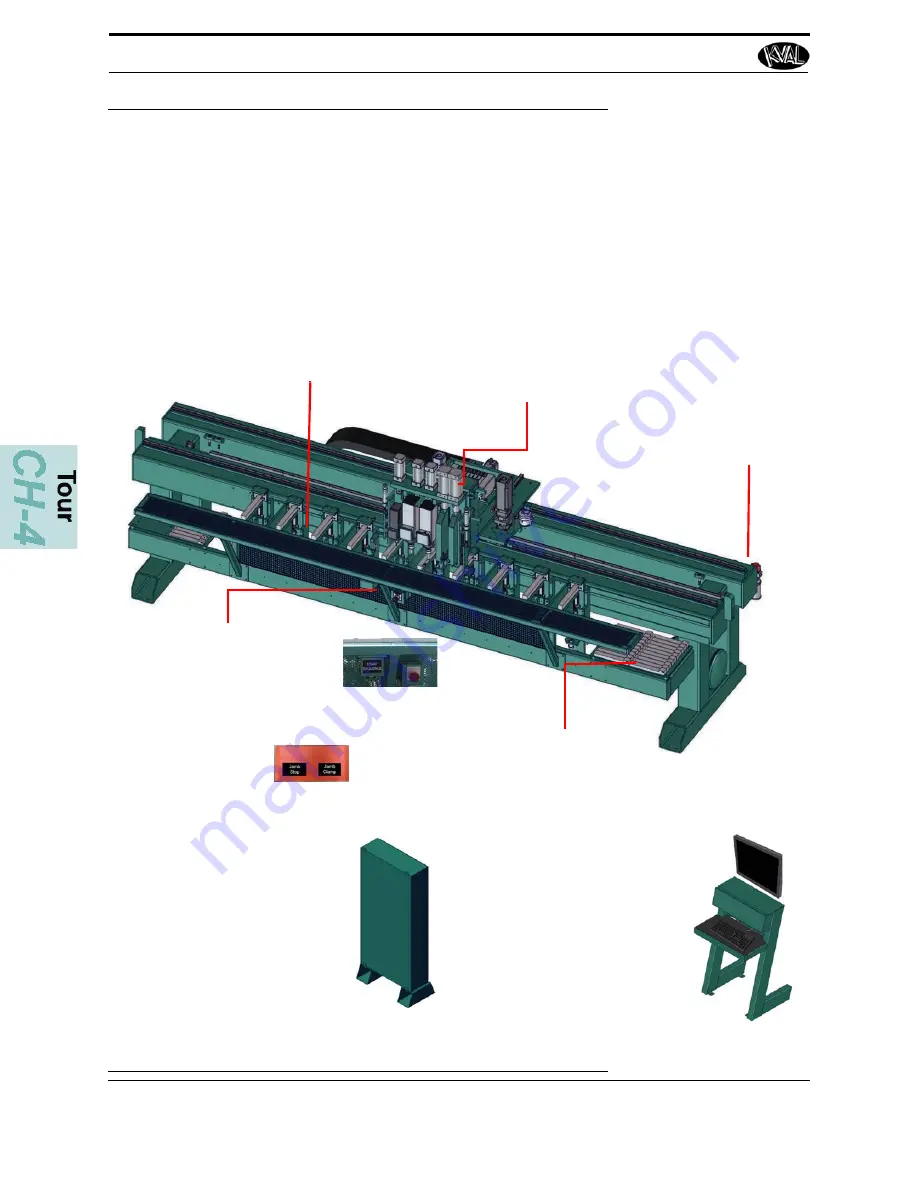

Front View of the 965X

4-2

965X Operation Manual

Front View of the 965X

At the front of the machine, the operator controls the jamb through the process. This includes

loading templates of the cut to be performed, controlling the path of the jamb, positioning the

jamb, and feeding the jamb thorough to the next machine. The

Figure below

identifies major

assemblies and controls.

FIGURE 4- 1.

Tour of Front of the Machine

Carriage Head:

Work Horse. Servo driven Tool Carriage to

rout and drill the face of a jamb.

Includes Left-Hand and Right-Hand Stops

to align with the top of the jamb

See “Assemblies on the Carriage Head” on

page 4-6 .

Jamb Clamps (x10):

The Jamb Clamps secure and align the jamb horizontally

and vertically. The clamps hold the jamb in a repeatable

reference to process the jamb. Also includes the Reference

Blocks on the Vertical Clamp.

See “Assemblies on the Carriage Head” on page 4-6 .

Operator Station:

The Operator’s Station includes a

touch screen, keyboard to run the

program that operates the

Contains mechanical Machine

Controls.

page 4-3 .

Foot Pedal Controls:

Jamb Clamp

Jamb Stop

See “Foot Pedal Control” on page 4-5 .

Electrical Panel:

Located behind the machine. Sup

-

plies voltages, control signals, and

contain s the machine computer.

See “Operator’s Station and Con

trols on the 965X” on page 4-3 .

Block Storage(x2):

Store Jamb Support Blocks and

catch trimmed excess of

jamb.

Air System:

Start Sequence and E-Stop:

Controls to start the cutting

process and Emergency Stop

the machine

See “Front Section Controls” on page 4-4 .

Содержание 965X

Страница 29: ...How to Download the Service Application 1 21 965X Operation Manual Page Intentionally Left Blank ...

Страница 103: ......