MDX [en-US]

32

Mount the bearing housing adjustment nut with adjusting screw onto the bottom of the housing. When placing the

bearing assembly onto the pedestal, ensure that the slotted tab on the pedestal fits into the slot of the adjusting screw.

The pedestal and bearing housing saddles should be clean, dry, and free from oil or grease. If corrosion of the saddles

is a problem, apply a thin film of preservative. Special care must then be taken in the axial adjustment procedure to

ensure that no movement may occur.

The bearing housing hold down bolts should now be installed, but should remain slightly loose until the axial adjustment

of the bearing housing is complete.

The assembly design locates the bearing assembly in machined ways and uses hex head cap screws to clamp the

housing down against the pedestal surface. An adjusting bolt is used to set the impeller nose clearance. This bolt

should not be considered as part of the locking mechanism.

All mating surfaces must be clean and dry. This means removing any paint, dirt, rust or lubricants from both the housing

and the pedestal to provide solid metal to metal contact.

Use a heavy hex nut that meets or exceeds the requirements of ASTM A194-2H. When properly torqued, these

fasteners will provide the clamping force required to hold the housing in place. Never replace any fastener with one of

a lesser grade.

Never replace any fastener with one of a lesser grade.

Fastener preparation and proper torque are most important. Clean the bolt and nut, and check the threads. Replace

any parts that show signs of damage, wear or galling.

Thread lubrication is crucial for obtaining the correct torque, and there are different values for various lubricants. GIW

recommends coating the threads with either copper or nickel based anti-seize. This provides thread lubrication for

correct clamp load at a lower applied torque and assists in routine fastener removal for future maintenance. If an

alternate lubricant such as heavy oil is used, torque values must be adjusted accordingly. Moly lube is not

recommended, since bolts can easily be over torqued.

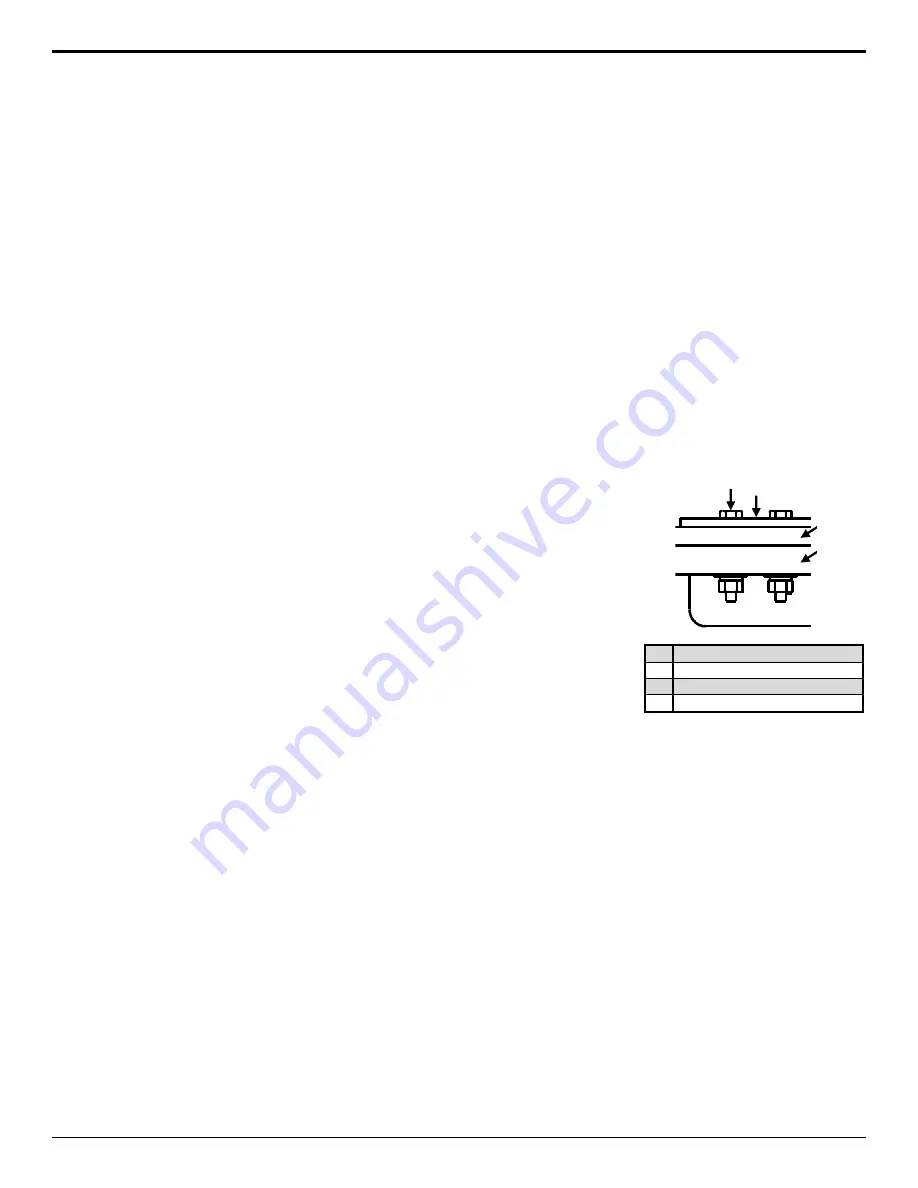

The bearing assembly hold down bolts are typically installed from the top. While

this is not ideal for torque, it makes assembly much easier. The flat strap is used

to help distribute the bolt forces along the cast bearing housing. Make sure that

this junction also has clean metal to metal contact. Flat washers and lock

washers are used under the nut distribute load. The nut should be held with a

box wrench while the bolt is tightened. As with any high torque bolted joint, the

fasteners should be brought up to the required specification in two or three

stages.

Verify the size of the bolts and use the following chart to determine the

tightening torque. Bolts should be SAE Grade 8 or Metric Class 10.9.

Fastener torque must be accurately measured to achieve the proper clamping

force. Air impact wrenches rarely deliver the correct torque due to variations in

air pressure and tool condition. These can be used to tighten the bolts, but the

final torque values should be achieved with a calibrated torque wrench. The use

of a Hydraulic Torque Wrench is recommended for larger fasteners, and these

tools can be calibrated to produce the necessary accuracy.

1 Bolt

2 Strap

3 Bearing Housing

4 Pedestal

1 2

3

4

Содержание GIW MDX

Страница 53: ...MDX en US 53 14 Notes...