7

5.5 Connecting the piping

Never use the pump itself as an anchorage point

for the piping.

The pump must not be subjected to any pipeline forces and

moments (for example by torsion, thermal expansion).

Suction lift lines shall be laid with a rising slope towards the

pump and suction head lines with a downward slope towards

the pump. The pipelines shall be anchored in close proximity

to the pump and connected without transmitting any stresses

or strains.

With short pipelines, the nominal diameters should be at least

equal to the nominal diameters of the pump nozzles. For long

pipelines, the most economical nominal diameter has to be

determined from case to case.

Adapters to larger diameters should have a diffuser angle of

approx. 8 in order to avoid any increase in pressure losses.

It is recommended to install check and shut-off elements in

the system, depending on the type of plant and pump.

Thermal expansions of the pipelines must be compensated by

appropriate measures so as not to impose any extra loads on

the pump exceeding the permissible pipeline forces and

moments.

An excessive, impermissible increase in the pipeline

forces may cause leaks on the pump where the medium

handled can escape into the atmosphere.

Danger of life when hot media are handled!

The flange covers on the pump suction and discharge nozzles

must be removed prior to installation in the piping.

Before commissioning new installations thoroughly clean,

flush and blow through all vessels, pipelines and connec-

tions.Often welding beads, scale and other impurities only

come off after a certain period of operation. Fit a strainer in the

suction line to prevent them from entering the pump. The total

cross-section of the holes in the strainer shall be three times

the cross-section of the pipeline in order to avoid excessive

pressure loss across the strainer due to clogging. Conical

strainers with laid-in wire mesh having a mesh width of 0.5

mm and a wire diameter of 0.25 mm, of corrosion-resistant

material, shall be used.

1 Strainer housing

2 Fine screen

3 Perforated plate

4 Pump suction nozzle

5 Differential pressure gauge

Fig. 5.5-1 Conical strainer for the suction line

5.5.1 Auxiliary connections

The dimensions and location of the auxiliary connection (drain

line) are indicated on the general arrangement drawing or pip-

ing layout.

5.5.2 Vacuum balance line

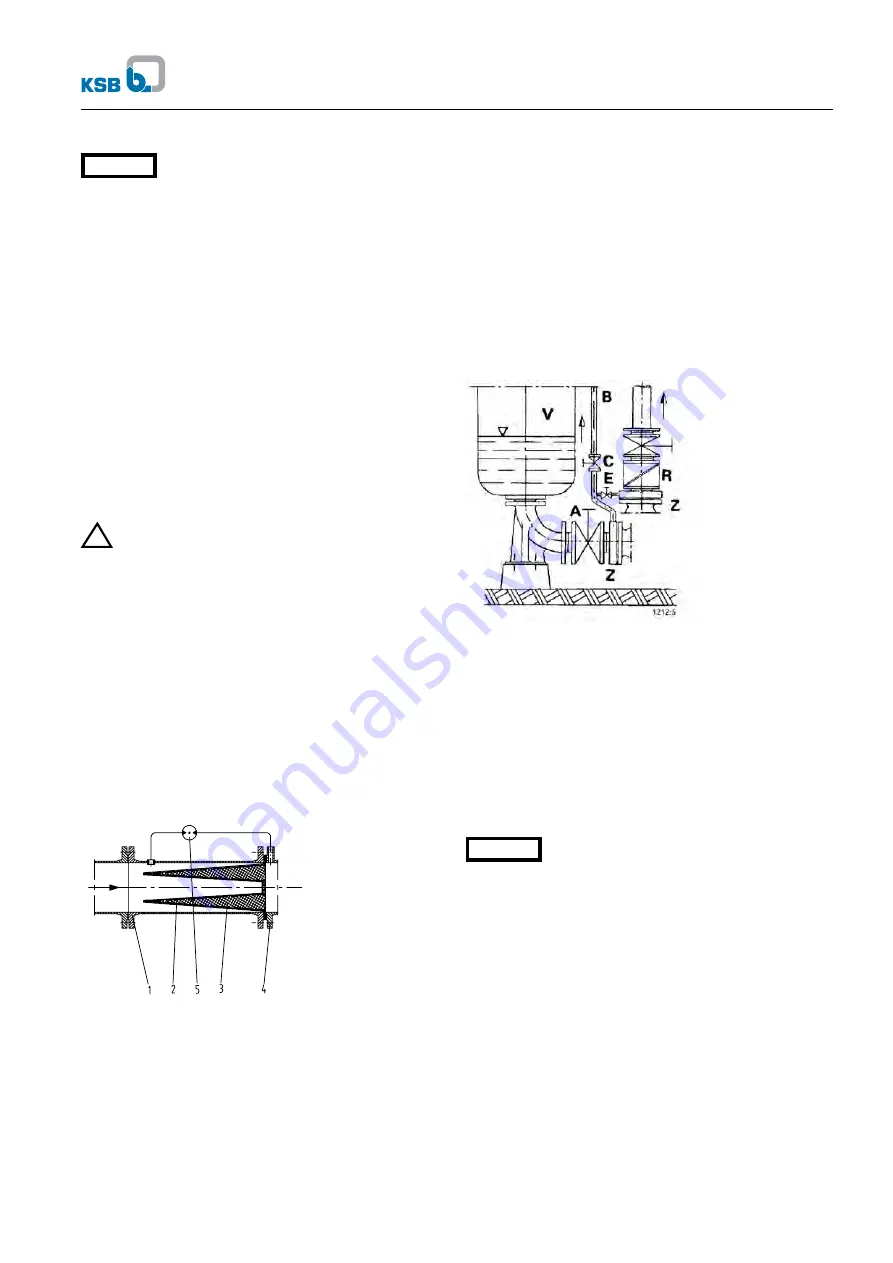

Where liquid has to be pumped out of a vessel under vacuum,

it is advisable to install a vacuum balance line. This line shall

have a nominal diameter of at least 25 mm and must be

arranged to lead into the vessel at a point above the highest

permissible liquid level.

An additional pipeline fitted with a shut-off valve – from the

pump discharge nozzle to the balance line – facilitates venting

of the pump before start-up.

A Main shut-off valve

B Vacuum balance line

C Shut-off valve

E Vacuum-tight shut-off valve

R Swing check valve

V Vessel under vacuum

Z Intermediate flange

Fig. 5.5-2 Suction line and vacuum balance line

5.6 Final check

Check the integrity and proper functioning of all

connections.

5.7 Connection to power supply

Connection to the power supply must be effected by a trained

electrician only.

The applicable DIN VDE regulations 0100 and, for explosion-

proof units, 0165 must be complied with.

Check available mains voltage against the data on the motor

rating plate and select appropriate start-up method.

All connections shall be effected in accordance with the

technical specifications issued by the local energy sup-

ply company.

We strongly recommend to use a motor protection device. DIN

VDE 0170/0171 stipulates that explosion-proof motors, type of

protection IP 54, increased safety Ex EEx, temperature class

T3, must always be connected via a motor protection switch.

121

1:

19/

4

Etabloc

!

Caution

Caution

Содержание Etabloc

Страница 1: ...Operating Instructions Close coupled Pumps Etabloc...

Страница 2: ......

Страница 19: ......

Страница 20: ...Etabloc Gartone Press Tel 011 440 6126 29 6 2004 Subject to technical modification without prior notice...