Rev. Date: 12/14/10

Page 17

MODEL #5200-P

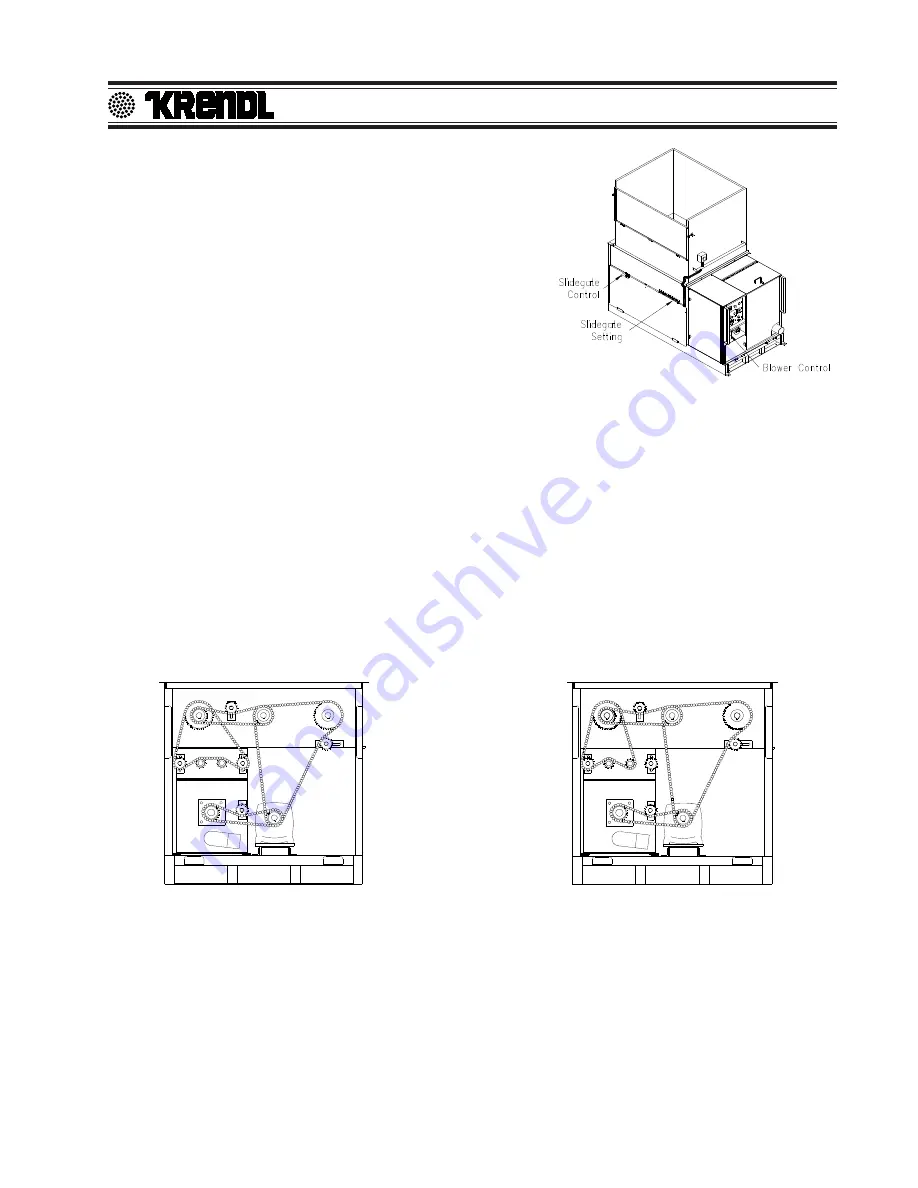

The blower and slidegate controls

working together

affect the distance fiber can be blown through a hose without

plugging. These controls also affect the accurate blowing of

fibers for spraying applications.

These settings control the following:

•

Density

of fiber blown in application.

•

Velocity

of material impact when spraying.

•

Dust

on open blow.

• Material

spread rate

or coverage.

•

Production

rate (lbs. per hour blown).

General Blower Control and Slidegate Settings for Open Blow:

With the

slidegate

closed and blower control valve on low (valve open), turn

agitator-feed and

blower on

. Fill hopper with insulation and adjust

blower valve

and

slidegate.

Move controls

proportional to each other. (i.e. If

blower valve

is half open,

slidegate

should be half open.) As hose

length is increased, air pressure/volume is increased by closing off the

blower valve

while closing the

slidegate proportionally. This will increase the distance fiber can be blown through the hose, while

decreasing the blowing production rate (lbs. per hour blown). (See illustration 7)

Shredder Assembly:

This unit is supplied with a shredder assembly; airlock/agitator speeds are preset at the factory.

No

further sprocket setting speeds are needed, as this system will accommodate most fibers and

applications. However, the shredder and agitator

direction

can be adjusted as described below.

Shredder & Agitator Adjustment:

Illustration 7

Unidirectional Rotation

(See illustration 8) is preferred as an all-around setting for a combination of

materials and applications. This setting provides the greatest

coverage

and

best control

for internal

wetting (stabilized) and open blow applications.

Center-Down Rotation

(See illustration 9) force feeds the fiber into the airlock at a faster rate. This

direction provides the greatest

production

for cellulose fibers in an open attic blow application

although coverage may decrease.

Illustration 8

Illustration 9

Содержание 5200-P

Страница 28: ...Rev Date 12 14 10 Page25 MODEL 5200 P PARTS LIST 5200 Exploded Parts View Unidirectional Center Down ...

Страница 29: ...Rev Date 12 14 10 Page26 MODEL 5200 P 5200 Exploded Parts View ...

Страница 30: ...Rev Date 12 14 10 Page27 MODEL 5200 P 5200 Exploded Parts View ...

Страница 36: ...Rev Date 12 14 10 Page33 MODEL 5200 P SERVICE RECORD DATE MAINTENANCE PERFORMED COMPONENTS REQUIRED ...