-13-

2.The Show Status of Computer Board

1.Computer Board

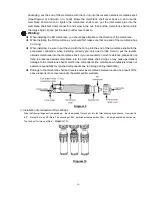

As (diagram12) show

Diagram 12

①

The work status of the indicator show

A.

Working status

;

B.

First cartridge replacement alarming

;

C.

Second cartridge replacement alarming

D .

Third cartridge replacement alarming

E.

Fifth cartridge replacement alarming

Working

:

The machine start working after 3 seconds when turn on the power

,

A~E display in turn.

Standby

:

A keep light and the pump stop working.

Shortage of water

:

A will flash and alarm 30 seconds when lack of water

,

the pump stop working

45 minutes protection

:

A light flash45 minutes and alarm 30 seconds when the machine continuelly

working 45 minutes , then stop working

,

the machine will work automatically after 45 minutes (cut off power

and restart don’t influence the function).

Filter cartridge replacement alarming:

It will be alarming when the first,and second filter cartridge used

after 80 hours accumulatively, the third,and fifth filter cartridge used after 100 hours accumulatively

,

the

corresponding indicator lights flashing 15 seconds and alarm 15 seconds when the filter cartridge need to be

replaced.

②

Reset after replacement of the filter cartridge

Open the cover, have No.1 and No.2 hole on the computer from left to right

,

No.1 is reset button

,

No. 2 is shift button.A stay

light under standby mode, , press no. 2 to choose the cartridge need to be reset

,

then press No.1 to reset.

3. Filter Replacement Method

①

Replacing the 1

st

and 3

rd

stage PP filters

First close the inlet water ball valve, using the filter cartridge wrench unscrew the 1

st

and 3

rd

stage

filter cartridges, remove the old filters, then take the new filters out of the packaging, finally place the

filters in the filter cartridges (Note: place the 5 micron PP filter in the 1

st

stage filter cartridge, the 1

micron PP filter in the 3

rd

stage filter cartridge), using the filter wrench, tighten the filter cover.

②

Replacing the 2

nd

stage granular activated carbon filter

First close the inlet water ball valve, using the filter cartridge wrench unscrew the 2

nd

stage filter,

remove the old filter, then take the new filter out of its packaging (the rubber pad on the filter does not

need to be taken off), finally place the filter inside the filter cartridge (note: the direction of the

granular activated carbon filter should be with the rubber pad end up towards the filter covers), use

the wrench to tighten the filter cover.

③

For replacement of membrane elements please see “RO Membrane Installation” (Page 8).

4. Notes

①

RO membrane water production volume

The RO membrane component water volume is influenced by the inlet water pressure and water

temperature, this machine’s stated volume of

8

00GPD

is

tested with

net

pressure

of

0.5MPa

and

inlet water temperature of 25

℃

, if the net pressure is less than 0.5MPa

or

if

the

inlet

water temperature is less than 25

℃

,

the

RO

membrane

element

water

production will be

less than

8

00GPD.

②

Disposal of old filters

A

B

D

C

E