73

72

!

!

!

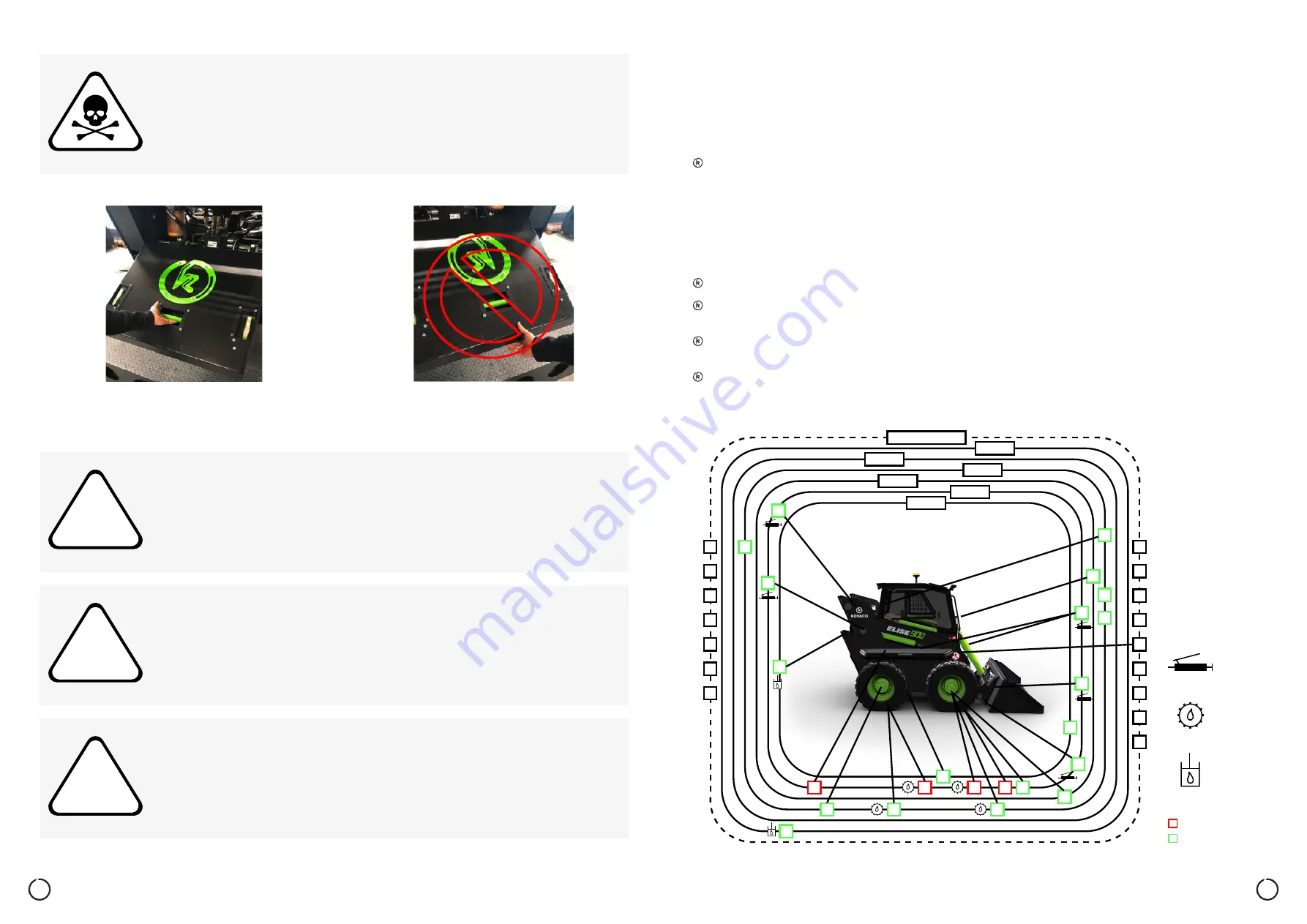

Correct grip of the machine bottom cover when handling.

Incorrect grip of the machine bottom cover when handling.

Picture 62

Picture 63

Danger

The battery may only be replaced by trained personnel. Replace on a paved and flat surface with

a maximum inclination of 1 ° (tarmac, concrete).

Warning

Do not secure the covers with any object!

Warning

Improper handling of the bottom cover can result in amputation of limbs!

Warning

If the machine top and bottom do not hold properly in their place by themselves, service is need-

ed, or the fault to be reported to service center!

Picture 64

17. PREVENTIVE MAINTENANCE

Maintenance is important and is the best protection against premature wear of the unit assemblies. Perform the prescribed

works to prevent possible malfunctions. In regular checks and inspections, it is possible to detect wear and malfunction,

and failures can be prevented by cleaning and lubricating, or tightening loose connections, removing leaks, etc.

Maintenance includes the following works:

Cleaning and care, recharging the battery, topping up lubricating greases, changing oils, checking all units, adjusting

clearances, checking mechanical joints and their tightening, etc.

For a better overview, we have included all maintenance works in tables according to the number of operating hours

worked. Read the number of operating hours on the control panel located in the cabin. Keep a record of the maintenance

works carried out in the machine’s warranty book. Maintenance is divided according to the inspection and maintenance

schedule.

The following common rules apply to all disassembly and assembly procedures:

Use the most suitable tools that do not damage the nuts or bolt heads.

Components that move relative to each other when assembled are not mounted dry. They need to be lubricated

with a designated lubricant for the respective component in service.

When assembling preserved components, the preservative grease must be removed and replaced with operating

lubricant.

Replace defective components only with original parts!

17.1 INSPECTION AND MAINTENANCE SCHEDULE

10 Mh

1

3

3

2

15

8

4

86

11

6

3

3

3

16

14

5

10

1

78

8

9

15

8

9

10

11

12

13

14

15

16

2

3

4

5

6

7

50 Mh

250 Mh

500 Mh

1000 Mh

1500 Mh

AS NEEDED

GREASE

GEAR OIL

HYDRAULIC OIL

FIRST-TIME MAINTENANCE

AT REGULAR MAINTENANCE INTERVALS

Содержание Elise900

Страница 1: ...Elise900 User Manual for Operation and Maintenance ...

Страница 2: ...KOVACO Electric a s 1st edition 2020 ...

Страница 44: ...Elise900 Manual for the Kovaco Application ...

Страница 50: ...NOTES NOTES ...

Страница 51: ...COPYRIGHT KOVACO Electric a s All rights reserved ...