.

MAINTENANCE

SERVICE PROCEDURE

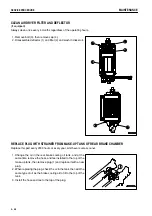

REPLACE FUEL FILTER CARTRIDGE

WARNING

Each part is at high temperature after the engine has been operated, so never change the filter immediately after finishing

operations. Wait for each part to cool down before changing it.

Do not bring fire or sparks near the fuel.

Prepare a filter wrench

1. Close supply valve (1) of the fuel tank.

2. Set the container to catch the fuel under the filter cartridge.

3. Using a filter wrench, turn filter cartridge (2) counterclockwise

to remove it.

4. Clean the filter holder, fill a new filter cartridge with clean fuel,

coat the packing surface with engine oil, then install it to the

filter holder.

5. When installing, tighten until the packing surface contacts the

seal surface of the filter holder, then tighten a further 1/2 to

3/4 turns.

If the filter cartridge is tightened too far, the packing will be

damaged and this will lead to leakage of fuel. If the filter is too

loose, fuel will also leak from the packing, so always tighten the

correct amount.

6. After replacing filter cartridge (2), loosen air bleed plug (3), and

open supply valve (1).

7. Loosen knob (4) (one each on left and right) of the feed pump,

and move it up and down to make the fuel overflow until no

more bubbles come out from air bleed plug (3).

8. Tighten air bleed plug (3), then push in knob (4) (one each on

left and right) of the feed pump, and tighten it.

9. After replacing the filter cartridge, start the engine and check

that there is no leakage of fuel from the filter seal surface. If

there is any leakage of fuel, check the tightening of the filter

cartridge. If there is still leakage of fuel, follow Step 2 and 3 to

remove the filter cartridge, then check the packing surface for

damage or foreign material. If any damage or foreign material

is found in the packing, replace the cartridge with a new part,

then repeat Steps 4 to 9 to install the filter cartridge.

When the engine is started after stopping because fuel is used up, if misfirming or black exhaust emission occur,

bleed air from the fuel line according to the following procedure.

10. Loosen the air bleed plugs of both injection pumps, bleed air by operating both feed pumps as explained in Steps

6 - 8 above.

Be sure to use both priming pumps to bleed air.

If any air remains in the fuel line, it can cause a problem in the fuel system.

4 - 55

Содержание HD785-5

Страница 2: ... 1 1 ...

Страница 4: ... FOREWORD FOREWORD 1 3 ...

Страница 5: ... FOREWORD FOREWORD 1 4 ...

Страница 15: ... 2 1 ...

Страница 19: ... SAFETY SAFETY LABELS POSITION FOR ATTACHING SAFETY LABELS 2 5 ...

Страница 47: ... 3 1 ...

Страница 132: ... OPERATION OPERATION Brake performance Downhill distace Continuous Tire size 27 00R49 3 86 ...

Страница 166: ... 4 1 ...

Страница 237: ... 5 1 ...

Страница 239: ... SPECIFICATIONS SPECIFICATIONS 5 3 ...

Страница 240: ... 6 1 ...

Страница 299: ... 7 1 ...

Страница 307: ... HD785 5 DUMP TRUCK Form No PEN00042 03 2006 KOMATSU All Rights Reserved Printed in Japan 04 06 ...