15.3

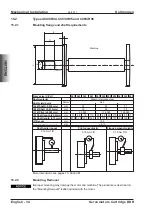

Types C09/CH09 and C13/CH13

15.3.1

Mounting flange and shaft requirements

Frame size (C/CH)

091

092

093

131

132

133

Shaft material

Cold-rolled steel with 0.3% carbon content

Shaft yield point

N/mm²

380

(A) Ø Shaft (-0.012mm)

mm

60

70

(B) Ø Shaft (-0.012mm)

mm

70

80

(C) Ø Pilot (±0.02mm)

mm

232.94

333.96

(D) Shaft length (±0.13mm)

mm

43.94

88.14

124.71

40.39

83.82

118.62

(E) Shaft length (±1.5mm)

mm

89.92

134.11

170.69

114.05

167.89

253.49

(F) Recess

mm

13.5

17.8

Axial shaft movement

mm

static ±1.5 / dynamic ±0.05

Shaft radial runout

Pilot concentricity

Flange perpendicularity

0.038 mm TIR

0.051 mm TIR

0.051 mm TIR

More dimensions see pages 82 and 83.

15.3.2

Mounting, Removal

Improper mounting may damage the motor and machine.The procedure is described in

the "Mounting/Removal" leaflet included with the motor.

Servomotors Cartridge DDR

English - 35

Kollmorgen

04/2017

Mechanical Installation

ENGLISH

B

C

E

A

F

Machine