MIM-

MIM 01/0419

page

7

7. Mechanical connection

7.1 Check operating conditions

flow rate

max. operating pressure

max. operating temperature

In general, MIM is subjected to the same loads as the piping into which it is

installed. The MIM should therefore be kept away from extreme loads, such as

pressure surges with strong, dynamic pipe movements, vibrations in the proximity

of centrifugal pumps, high temperature media, flooding etc.

7.2 Installation

Remove all packing materials and transport retainers and ensure that no such

materials remain in the device.

It can be installed in vertical, horizontal or rising pipes. Flow in direction of the

arrow.

Avoid pressure and tensile load.

Mechanically secure the inlet and outlet pipe at a distance of 50 mm from the

connections.

Avoid valves or large reduction on the inlet section (this increases the

inaccuracy of measurements).

Check the leak tightness of the connections.

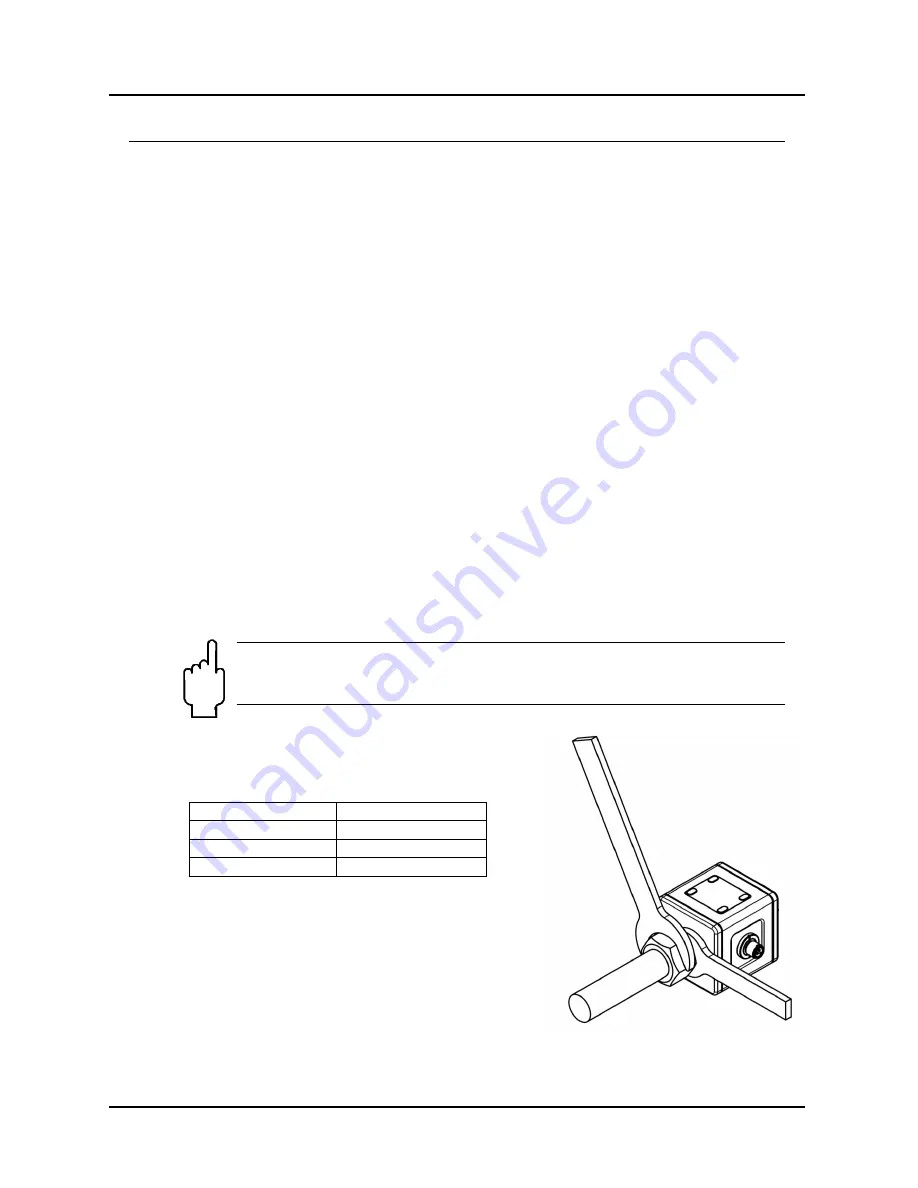

While mounting MIM hold the flowmeter from fitting surface (not

from the housing) with a wrench.

Take into account the tightening torque.

Nominal size

Tightening torque

½“

22 to 24 Nm

¾“

28 to 30 Nm

1“

28 to 30 Nm