3

GENERAL SAFETY RULES

ELECTRICAL

EXTENSION CORDS

Use only 3-wire extension cords that have 3-prong grounding

plugs and 3-pole receptacles that accept the tool’s plug.

When using a power tool at a considerable distance from the

power source, use an extension cord heavy enough to carry

the current that the tool will draw. An undersized extension

cord will cause a drop in line voltage, resulting in a loss of

power and causing the motor to overheat. Use the chart

provided below to determine the minimum wire size required

in an extension cord. Only round jacketed cords listed by

Underwriter’s Laboratories (UL) should be used.

When working with the tool outdoors, use an extension cord

that is designed for outside use. This is indicated by the

letters “W-A” or “W” on the cord’s jacket.

Before using an extension cord, inspect it for loose or

exposed wires and cut or worn insulation.

WARNING

Keep the extension cord clear of the

working area. Position the cord so that it will not get

caught on lumber, tools or other obstructions while

you are working with a power tool. Failure to do so

can result in serious personal injury.

•

NEVER START A TOOL WHEN ANY ROTATING

COMPONENT IS IN CONTACT WITH THE WORKPIECE

.

•

DO NOT OPERATE A TOOL WHILE UNDER THE

INFLUENCE OF DRUGS, ALCOHOL, OR ANY

MEDICATION

.

•

WHEN SERVICING

use only identical replacement parts.

Use of any other parts may create a hazard or cause

product damage.

•

FIRMLY CLAMP OR BOLT

your tool to a workbench or

table at approximately hip height.

•

NEVER

stand or have any part of your body in line with

the path of the workpiece.

•

PLAN YOUR WORK TO REDUCE THE RISK OF

THROWBACKS

(when the workpiece catches the sanding

drum and is torn from your hands).

•

MAKE SURE THERE’S NO DEBRIS

between the

workpiece and its supports.

•

WHEN SANDING IRREGULARLY SHAPES

WORKPIECES

, plan your work support so it will not slip

and be pulled from your hands.

•

USE EXTRA CAUTION WITH LARGE

, very small or

awkward workpieces.

•

NEVER USE THIS TOOL

to finish pieces too small to

hold by hand.

•

USE EXTRA SUPPORTS (TABLES, SAW HORSES,

BLOCKS, ETC.)

for any workpieces large enough to tip

when not secured to the work surface.

•

NEVER

sand more than one piece at a time. DO NOT STACK

more than one workpiece on the sander table at a time.

•

ALWAYS FEED WORKPIECE FROM LEFT TO RIGHT

against the direction the drum sleeve is rotating.

•

DO NOT USE DRUMS

, sanding sleeves or belts which

show visual signs of wear such as grooves, tears or rips.

•

ALWAYS STAY ALERT!

Do not allow familiarity (gained

from frequent use of your sander) to cause a careless

mistake. ALWAYS REMEMBER that a careless fraction

of a second is sufficient to inflict severe injury.

•

USE ONLY RECOMMENDED ACCESSORIES

listed

in this manual or addendums. Use of accessories that

are not listed may cause the risk of personal injury.

Instructions for safe use of accessories are included

with the accessory.

•

DOUBLE CHECK ALL SETUPS

. Make sure the spindle

or sanding belt assembly is tight and not making contact

with sander or workpiece before connecting to

power supply.

SPECIFIC SAFETY RULES

•

MAKE SURE THE WORK AREA HAS AMPLE LIGHTING

to see the work and that no obstructions will interfere with

safe operation BEFORE performing any work using your

tool.

•

ALWAYS TURN OFF THE SANDER

before disconnecting

it to avoid accidental starting when reconnecting to power

supply. NEVER leave the tool unattended while connected

to a power source.

•

SUPPORT WORKPIECE

with miter gauge, work rest, or

worktable.

•

MAINTAIN 1/16 in.

clearance between worktable and

sanding belt or disc.

•

AVOID KICKBACK

by sanding in accordance with

directional arrows.

•

IF THE POWER SUPPLY CORD IS DAMAGED

, it must

be replaced only by the manufacturer or by an authorized

service center to avoid risk.

•

THIS TOOL

should have the following markings:

a) Wear eye protection.

b) Support workpiece with miter gauge, backstop

(work support), or worktable.

c) Maintain 1/16 in. maximum clearance between

work table and sanding belt or disc.

d) Do not perform any operation freehand.

e) Avoid kickback by sanding in accordance with

directional arrows.

•

SAVE THESE INSTRUCTIONS

. Refer to them frequently

and use them to instruct others who may use this tool. If you

loan someone this tool, loan them these instructions also.

25’ 16 16 16 16 14 14

50’ 16 16 16 14 14 12

100’ 16 16 14 12 10 -

**Ampere rating (on tool data plate)

0-2.0 2.1-3.4 3.5-5.0 5.1-7.0 7.1-12.0 12.1-16.0

Cord Length Wire Size (A.W.G.)

**Used on 12 gauge - 20 amp circuit. NOTE: AWG = American Wire Gauge

WARNING

Check extension cords before each use.

If damaged replace immediately. Never use tool with

a damaged cord since touching the damaged area

could cause electrical shock resulting in serious injury.

Содержание KN BD-46B

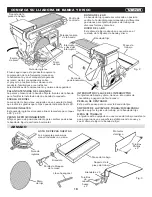

Страница 1: ...KN BD 46B Belt and disc sander 4 x6 101 6 mm 914 4 mm Lijadora de banda y disco ...

Страница 14: ...Belt and disc sander 4 x6 101 6 mm 914 4 mm Lijadora de banda y disco KN BD 46B SCHEMATIC VIEW 13 ...

Страница 28: ...VISTA ESQUEMATICA 27 Belt and disc sander 4 x6 101 6 mm 914 4 mm Lijadora de banda y disco KN BD 46B ...

Страница 29: ...www knova com mx ...