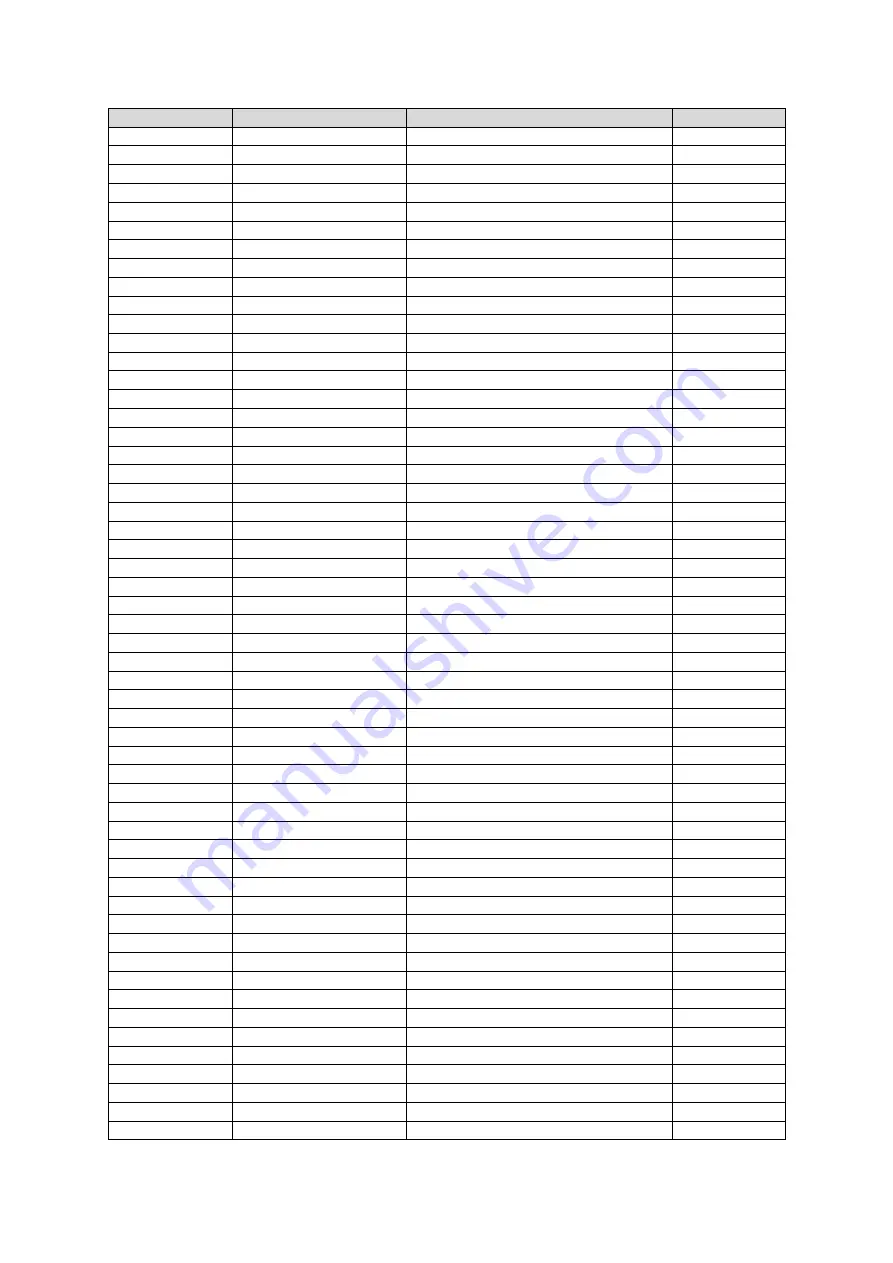

Page 17 of 20

Reference

Part Number

Part Description

Quantity

53

56

Blade

1

54

57

Bevel plate

1

55

58

6201ZZ Ball bearing

2

56

59

32mm Retaining ring

1

57

60

Rear blade wheel

1

58

61

M8X12mm Flat head screw

1

59

62

4X4X20mm Key

1

60

63

Front blade wheel

1

61

64

Flat washer

1

62

65

M6X12mm Flat head screw

1

63

66

Frame

1

64

67

Spring washer

8

65

68

Blade tension knob

1

66

69

Cord clamp

2

67

70

M5X 8mm Pan head screw

2

68

71

M6X8mm Set screw

69

72

Lock handle

1

70

73

6mm Flat washer

1

71

74

M6 Nut

4

72

75

6mm Lock washer

4

73

76

6mm Flat washer

4

74

77

Rear blade guide block

1

75

78

625ZZ Ball bearing

2

76

79

5mm Flat washer

4

77

80

5x24mm Pin

1

78

81

M6X25 Socket head screw

1

79

82

6mm Lock washer

1

80

83

Blade guard

1

81

84

6mm Flat washer

4

82

85

607ZZ Ball bearing

8

83

86

Shaft

4

84

87

6mm Flat washer

2

85

88

6mm Lock washer

2

86

89

M6X25mm Socket head screw

2

87

90

M5X10mm Socket head screw

1

88

91

5mm Flat washer

1

89

92

Guard plate

1

90

93

5X35mm Pin

1

91

94

Front blade guide block

1

92

95

M6 Nut

1

93

96

M6X25mm Socket head screw

1

94

97

M16-1.5mm Nut

1

95

98

Center shaft

1

96

99

Torsion spring

1

97

100

Lock handle

1

98

101

10mm Flat washer

1

99

102

Swivel support

1

100

103

12mm Flat washer

1

101

104

M12 Nut

1

102

105

M6X25mm Hex head bolt

1

103

106

M6 Nut

1

104

107

M6X35mm Socket head screw

1

105

108

6mm Flat washer

1

106

109

M5X10mm Socket head screw

2

Содержание 101670

Страница 15: ...Page 15 of 20 Parts Diagram...