Page 16 of 20

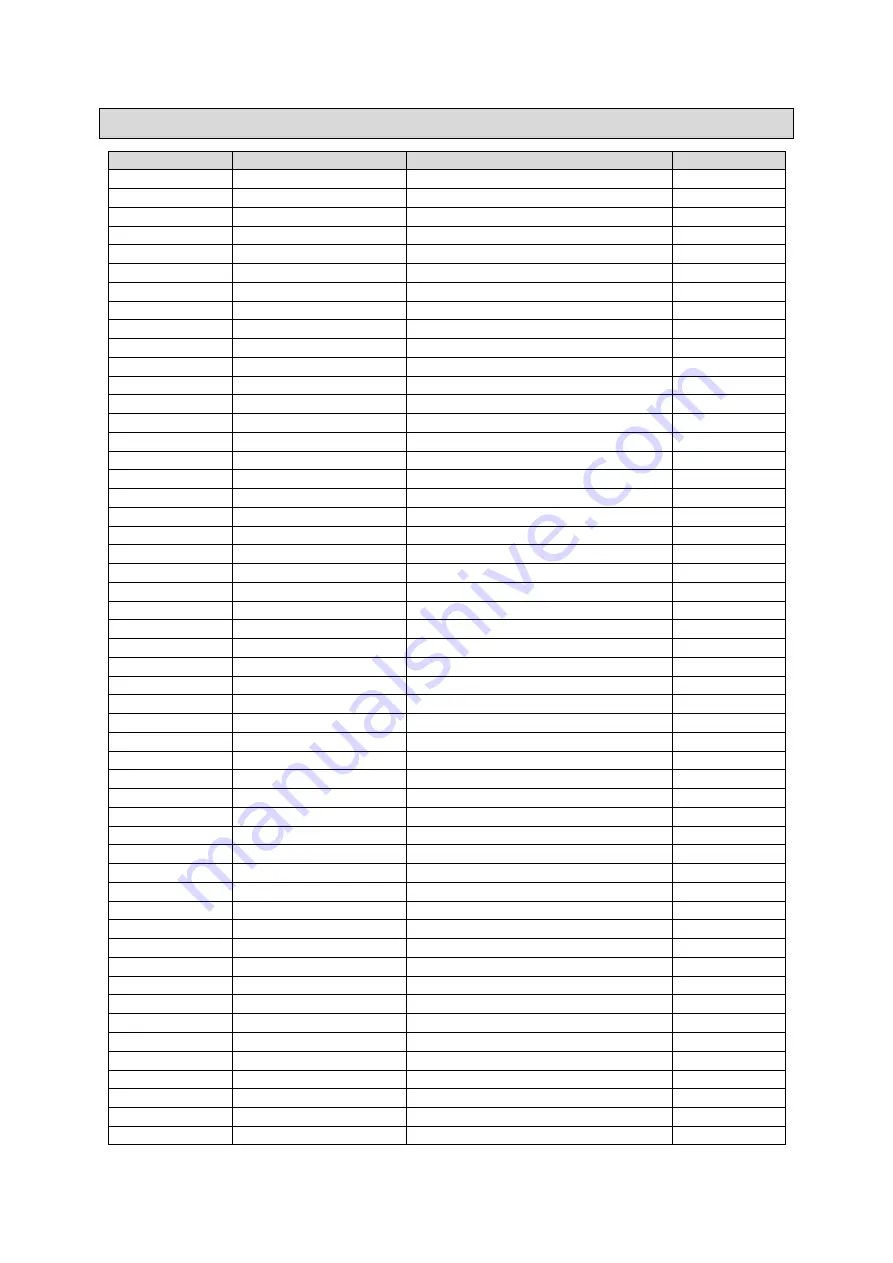

Parts List

Reference

Part Number

Part Description

Quantity

1

1

Speed adjusting knob

1

2

2

Circuit breaker

1

3

3

Motor housing

1

4

4

2.9-1X13mm Thread forming screw

2

5

5

Motor driver

1

6

6

M4X8mm Pan head screw

3

7

7

M4X8mm Pan head screw

1

8

8

4mm Serrated washer

1

9

9

Motor assembly

1

10

10

M5X10mm Socket head screw

4

11

12

Strain relief

1

12

13

Switch

1

13

14

2.9-1X9.5mm Thread forming screw

2

14

15

Switch box

1

15

16

Indicator light

1

16

17

4mm Flat washer

2

17

18

2.9-1X16mmThread forming screw

2

18

19

Power cord

1

19

20

Inner line

1

20

21

Front wheel shaft

1

21

22

5x5x10mm Key

1

22

23

15mm Retaining ring

1

23

24

50T Gear

1

24

25

6202ZZ Ball bearing

2

25

26

35mm Retaining ring

2

26

28

607ZZ Ball bearing

2

27

29

11mm Retaining ring

1

28

30

43T Gear

1

29

31

4x4x6mm Key

1

30

32

Pinion gear

1

31

34

M8X25mm Socket head screw

4

32

35

8mm Flat washer

4

33

36

Gear box

1

34

37

Frame cover

1

35

38

M5X8mm Pan head screw

6

36

39

5mm Flat washer

6

37

40

Left handle part

1

38

41

Button

1

39

42

Spring

1

40

43

Operating switch

1

41

44

Cord clamp

5

42

45

M5X10mm Pan head screw

5

43

46

Right handle part

1

44

47

2.9-1X9.5mm Thread forming screw

3

45

48

M4X8mm Flat head screw

4

46

49

Tube

1

47

50

Guide plate

2

48

51

M5X10mm Socket head screw

4

49

52

M8X25mm Socket head screw

2

50

53

8mm Lock washer

2

51

54

M8X10mm Set screw

1

52

55

Sliding block

1

Содержание 101670

Страница 15: ...Page 15 of 20 Parts Diagram...