EHP4230

3

Instruction Manual

GB

HE.12929_E © 05/2011

8.2 Hole making

As indicated prior the knockout sizes are adjusted by the

speed adjustment button. The punch must be turned onto

the draw stud until there is a

fi

rm contact with the sheet

metal. The knockout cycle is started by actuating the sa-

fety foot switch. Just before or shortly after completing the

knockout the pump switches into the creep speed. The

user gains a signi

fi

cant amount of time to release the foot

switch, respectively end the knockout cycle in order to

avoid a fatal contact between punch and die.

8.3 Bending

Operating the pump with the Bus Bar Tool Center (BBTC)

the approach switch with the hand trigger must be con-

nected to the pump via the socket (pic. 1.2) as well as

the hydraulic hose. The user can now decide with which

speed he prefers to operate the piston of the Bus Bar Tool

Center (BBTC). The speed can be adjusted via the speed

adjustment button (pic. 1.3). The retraction stop mode

allows the operator to slowly approach the required ben-

ding radius.

8.4 Cutting

A cutting cycle is usually performed in the normal mode,

which means that the cutting cycle is terminated automa-

tically after the max. operating pressure is reached or ter-

minated manually when the cable is cut.

8.5 Crimping

When crimping cable lugs and connectors the retraction

mode allows a better positioning or clamping function

which assists in producing perfect crimps. Actuating the

safety foot switch respectively the two hand safety con-

trol starts the crimping cycle. In the retraction mode when

releasing the safety foot switch or two hand control the

piston remains in its position and does not retract.

Attention

In case of an handling error the piston can be re-

tracted by a very brief actuation or by stepping

down the actuator of the safety foot switch also

in the retraction mode.

The crimping cycle continues when actuating the safety

foot switch again from the very position in which it was

interrupted. The crimping cycle runs automatically and

does not switch off before the max. operating pressure

is reached. In the retraction mode the retraction of the

piston can be stopped by actuating the foot switch.

Attention

The working process can be interrupted at any

moment by releasing or stepping down the ac-

tuator of the safety foot switch.

Once the three step safety foot switch has been stepped

down, it can only be reactivated by pushing the reset but-

ton of the foot switch. This reset button (pic. 1.10) is loca-

ted on the top of the foot switch.

Attention

Before changing the dies, respectively

blades of the tools attached to the pump

unit switch off the power to avoid uninten-

ded operation.

4.2 Explanation of the application range

The electro-hydraulic pump unit type EHP4 can be con-

nected to all punching, crimping and cutting heads, res-

pectively with all remote heads, of our product range.

Attention

Do not punch, crimp on or cut or operate

this unit on live lines.

Before starting to work on electric lines the user must

make sure that none of the parts in the working area of

the operator is live.

The units are not designed for continued operation. After

approximately 100 crimps respectively 80-50 cuts conse-

cutively a short break of at least 15 minutes is necessary

to let the unit cool down.

Attention

Too intensive use can cause heat damages to

the tool

Attention

During the operation of electric engines sparks

can occur which might ignite highly infl ammab-

le or explosive liquids and materials

Attention

Electro-hydraulic crimping/cutting tools should

not be operated in pouring rain or under water.

The unit can be operated in a temperature range from

-20°C to +40°C indoors and outdoors.

Before connecting the device to the public mains network

supply, the local power distribution supplier need to be

informed.

4.3 Service and maintenance instruction

The electro-hydraulic unit must be cleaned and dried after

each use. The pump is basically maintenance free, only

the oil level must be checked regularly and the pump has

to be inspected for possible damages and wear.

The EHP4 is equipped with an oil level control glass (pic.

1.5) which enables the operator the check the oil level of

the pump.

The oil level should be 10 mm below the top of the control

glass. If the oil level is too low please

fi

ll up the oil ac-

cordingly.

The following hydraulic oils are suitable for a temperature

range -20°C to +40°C:

Hydraulic oils based on Ester:

Rivolta S.B.H. 11, Shell

Naturell HF-E 15

Mineral oils:

Shell Tellus T 15, AVIA HVI 15, Mobil DTE 11,

NUTO H 15, Rando HD - Z15, Agip OSO 15, BP Energol

HLP 15.

Other equivalent hydraulic oils can also be used.The hy-

draulic hose (pic. 1.9) and the armature must be checked

for damage and leakage.

4.4 Oil changing and maintenance cycles

It is advisable to have the pump serviced by a specialist

during regular intervals to safeguard a technically proper

state before use.

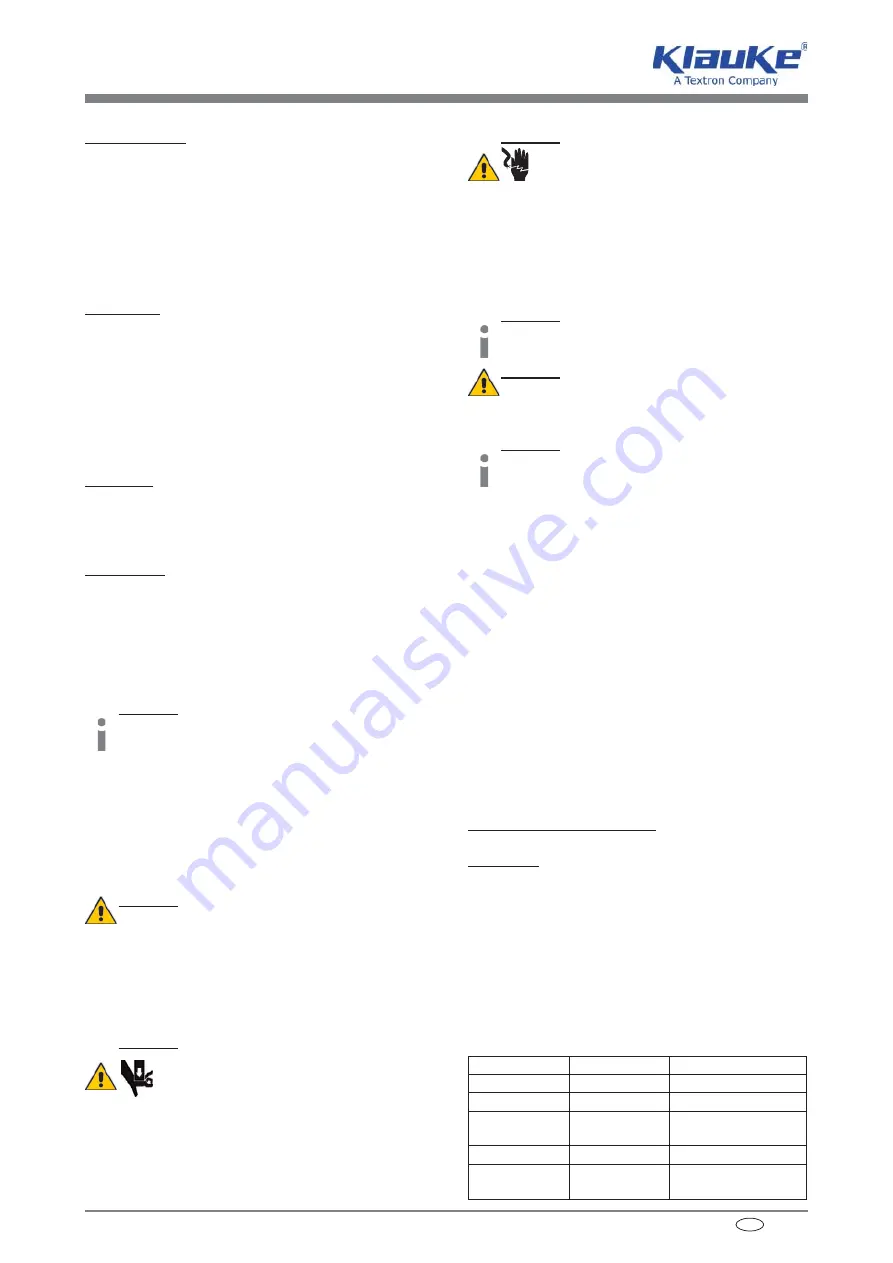

Table 2 - Service schedule

What

When

Who

Cleaning

after each use Service personnel

Check oil level weekly

Service personnel

Check high

pressure hose

weekly

Specialist

Proper state

quarterly

Electric specialist

Change

hydraulic oil

annually

Manufacturer/

Specialist