PNEUMATIC LEVEL CONTROLLER

PNEUMATIC LEVEL CONTROLLER

MODEL: GEN 3

Installation, Operation & Maintenance Guide

MODEL: GEN 3

Installation, Operation & Maintenance Guide

9

www.kimray.com

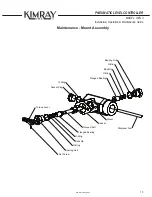

Paraffin Cleanout Port

The Gen 3 is equipped with an access port to give the

ability to inspect and clean out the area inside the Mount,

without having to remove the unit from the vessel.

This can help if there are paraffins or other solids that

build up over time inside the Mount, restricting movement

of the Displacer Rod.

WARNING:

Make sure all pressure is released

from the vessel before loosening the cleanout port plug.

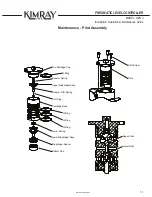

Repair Kit Replacements

Repair kits contain all seals and wear components

recommended to be replaced during scheduled

maintenance intervals for the entire unit, including

Pilot, Well-Wetted, and Adjustment Spring Assembly

Components. The following sections instruct how

to replace these components. A list of repair kit

components can be found in the kit sheet RK:F001.

Other Replacements

If any other components that were inspected need to be

replaced, use the Technical Specs document 08:05.1 to

determine which part number(s) are needed and contact

your local Kimray authorized store or distributor to order.

WARNING:

A leaking controller is an indication that service is

required. Failure to take controller out of service

immediately may cause a hazardous condition.

WARNING:

Before beginning repair, Block & Bleed valve. Make sure

all pressure is released from vessel, and confirm no

pressure remains in supply gas/instrument air lines.

To locate an authorized Kimray repair facility or to find

your local Kimray authorized Distributor visit Kimray.com.

When conducting repairs, only use genuine Kimray repair

kits and replacement parts. Repair kits and detailed

repair instructions & videos are available at Kimray.com

Perform maintenance on a regular basis. An initial

inspection interval of 6 months is recommended.

Depending on the service conditions and the condition of

the controller, the inspection interval may be decreased

or increased.

The pilot can be repaired without removing the controller

from the vessel as long as the supply air/gas pressure

has been bled down and fully released.

Maintenance

Содержание GEN 3

Страница 1: ...PNEUMATIC LEVEL CONTROLLER GEN 3...

Страница 20: ...2018 Kimray Inc RM 0021 Issued 3 21 Kimray com...