Kendrion Binder Magnete GmbH

Operating Instructions 76 ..P..B00

Last updated: 30 Dec. 2009

Page 19

Deep groove ball bearing (18):

When performing maintenance and repair work, check that the deep groove ball bearing (18) rotates

smoothly. If the bearing (18) needs to be replaced, proceed as described above under "Brake removal from

the machine (e.g. motor)" and "Opening the solenoid housing (1.1)". After having removed the friction disc

(5), remove the circlips (14 and 15). Push the hub (17) and deep groove ball bearing (18) out of the solenoid

housing (1.1) and remove the bearing (18) from the hub (17). Before reassembling the spring-applied brake,

all components (except for the friction disc (5)) must be cleaned with grease-free cleaners. In order to

assemble the individual components, proceed in reverse order of removal. When fine adjusting the M

2

rated

torque, make sure that the machine screws (32) project from the flange (3) by the length x

nom

(approximate

value – see Table 17/1) marked on the flange (3). The self-locking nuts (31) (to ISO 10511-04-A2F; 140°C)

must be replaced before adjusting the screws.

Attention!

When the spring-applied single-disc brake is mounted to the machine, it is crucial that the fixing screws (10)

be tightened applying the M

A

tightening torque specified in Table 7/1. The machine screws (20) on the cover

(7) and the machine screws (22) must be tightened to the M

A

torque specified in Table 13/1. The O-ring (24),

spring washer (21 and 28) and flat seal (9) must be installed as shown in Fig. 6/1.

Attention!

Depending on its operating condition, it may no longer be possible to release the spring-applied single-disc

brake when the maximum air gap s

max

(see "Technical specifications") has been exceeded. In this case, the

braking effect cannot be neutralised.

Warning!

If a hand release lever (29) is fitted to the brake and the maximum air gap s

max

(see "Technical

specifications") has been exceeded (especially in case of a reduced M

2

rated torque), the hand release lever

(29) may limit the axial movement of the armature (2). This would cause the torque to be reduced down to

zero. Whenever carrying out maintenance work, check the degree of wear of the friction disc (5) and the air

gap 's' and replace the friction disc (5) well before the maximum air gap s

max

(see "Technical specifications")

is reached.

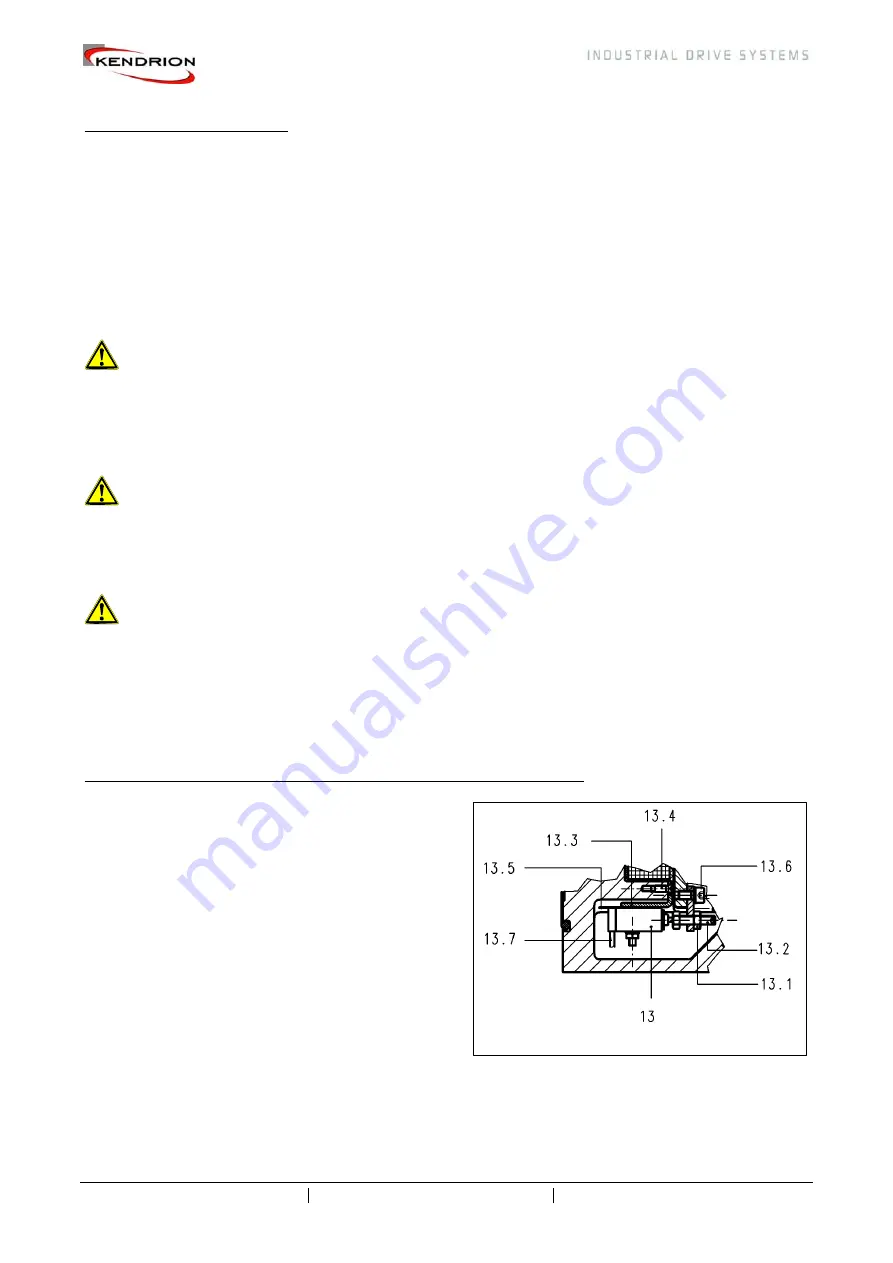

Microswitch (13) adjustment or replacement (only brakes with microswitch):

The spring-applied single-disc brake must be released

electrically to allow the microswitch (13) to be adjusted.

Loosen the machine screws (20) provided on the cover

(7) and remove the cover (7). Unscrew the locknut

(13.1) and turn the set screw (13.2) clockwise until the

microswitch (13) switches (slight audible click or contact

closure between contacts 5 and 6 (see Section 3.3). If

the microswitch (13) is in ON position, it must be turned

anticlockwise to OFF. After the changeover position has

been reached, continue to turn the set screw (13.2) by

60° to 90°. Tighten the locknut (13.1). Make sure the set

screw (13.2) position remains unchanged when

tightening the locknut. Switch the brake on and off to

check that the microswitch is in perfect working order. If

the microswitch (13) needs to be replaced (e.g. when

the maximum service life (switching operations) has been reached) (see "Technical specifications"), such

work must be carried out by the manufacturer or by an authorised repair shop due to the difficult installation

of the microswitch with the four thermoswitches (11 and 12).

Fig. 19/1: Microswitch adjustment