7

A7 MIG Welder

© Kemppi Oy 2020

2002

INTEGRA

TION GUIDE

3.3 Power source

Place the machine on a sturdy, level surface that is dry

and will not allow dust or other impurities to enter the

machine’s cooling air flow. Preferably, situate the machine

in a suitable carriage unit so that it is above floor level.

• The surface inclination may not exceed 15

degrees.

• Ensure the free circulation of cooling air. There

must be at least 20 cm of free space in front

of and behind the machine for cooling-air

circulation.

• Protect the machine against heavy rain and direct

sunshine.

Do not operate the machine in the rain.

Never aim the spray of sparks from a grinding machine

toward the equipment.

The power plug

The power source comes without a plug for connection

to the electrical grid. Attach a plug suitable for your

power-supply standard to the power cable. Check the

connections, attach the plug to a socket, and switch the

electrical power on from the welding power source to

verify that the machine works properly.

Switch the machine off, and unplug it from the power

socket before continuing to further steps in the hardware

installation.

If local or national regulations specify that an

alternative power cable is required, the cable must be

replaced in conformity with the regulations. Connection

and installation of the power cable and plug should be

carried out only by a suitably qualified person.

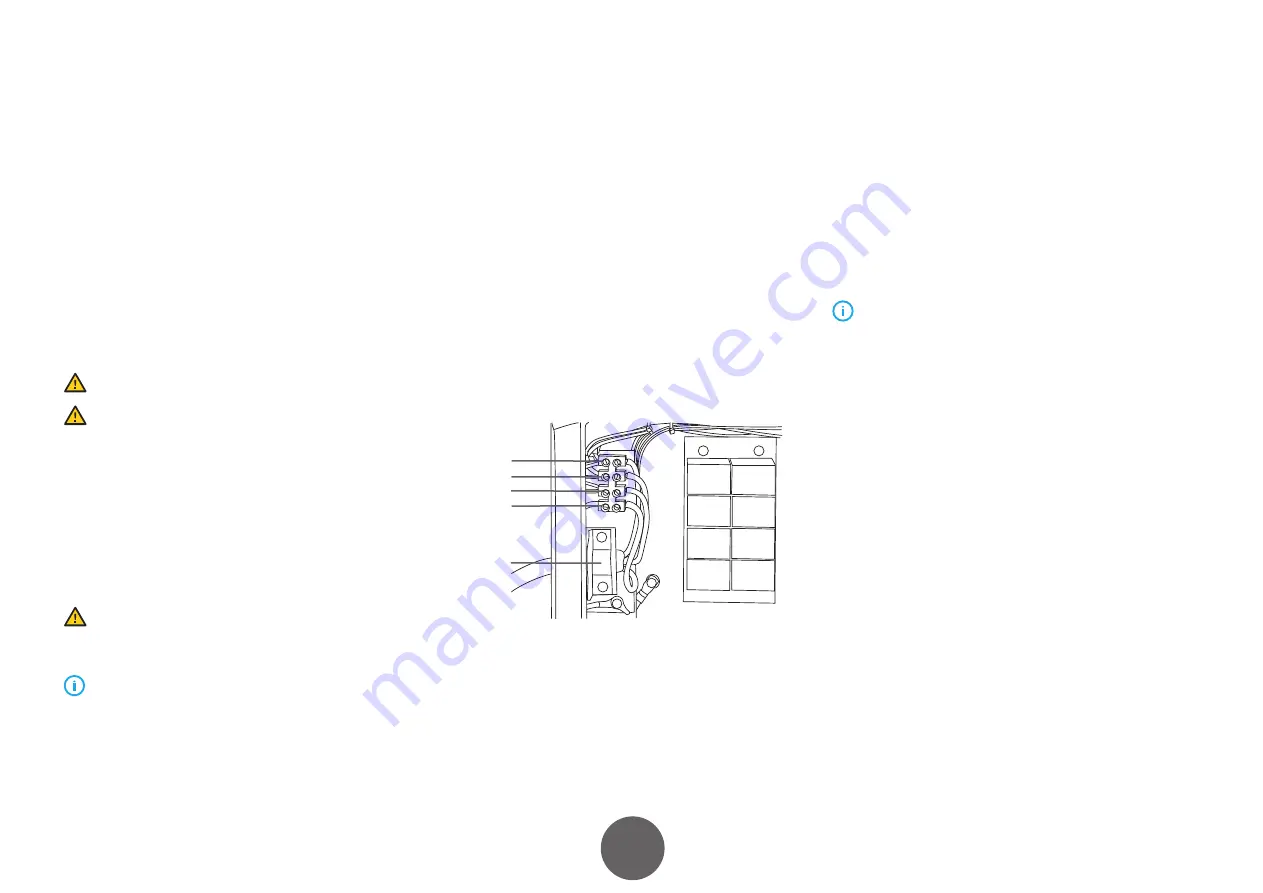

Remove the machine’s left-hand cover plate to enable

attachment of an electrical cable. The power source unit

can be connected to a 400 V, 3~ power supply.

If changing the power cable, take the following facts

into consideration:

• The cable enters the machine through the inlet

ring on the rear panel and is fastened in place

with a cable clamp (05).

• The phase conductors of the cable are coupled to

connectors L1, L2, and L3.

• The protective ground line, colored green and

yellow, is coupled to the marked connector.

• If you are using five-lead cable, do not connect

the neutral conductor.

05

*

L3

L2

L1

*

In S-type cables there is a protective grounding conductor,

green-and-yellow striped.

3.4 Cooling unit

If you use a water-cooled welding torch, you need a

cooling unit installed as part of the welder system. Attach

the cooling unit to the power source. See the detailed

installation instructions in the operating manual delivered

with the cooling unit package.

The cooling hose connections are described in

Subsection

3.8.5, “Cooling hoses.”

The wire feeder has no connectors for cooling hoses.

Use a special adapter to connect the cooling hoses to the

welding torch cooling connectors.

3.5 Wire feeder

Use a two-part mounting bracket to mount the wire

feeder securely on the robot arm. Fasten the upper part of

the bracket to the bottom of the wire feeder and the lower

part to the robot arm. Finish the installation by putting the

bracket parts together and fixing them in place with bolts.

See the illustrated instructions included in the product

delivery package.

Mounting brackets are available for the most commonly

used welding robots. See the complete list at

www.kemppi.com

.

The wire feeder connections are described in

Section 3.8,

“Interconnection cable set.”

Содержание A7 350

Страница 1: ...350 450 1920310 2002 A7 MIG Welder A7 MIG Welder EN INTEGRATION GUIDE...

Страница 60: ...And you know...