Installation

Page 44

•

Be sure to use two spanners and proper torque to

fasten the nut, too large torque will damage the

bellmouthing, and too small torque may cause

leakage. Refer the following table for different pipe

connection.

Pipe Diameter

Torque

Sketch map

N.

m(lb.ft)

1/4" (6.35)

18~20

(13.3~14.8)

3/8" (9.52)

32~39

(23.6~28.8)

1/2" (12.7)

49~59

(36.1~43.5)

5/8" (15.9)

57~71

(42~52.4)

3/4" (19)

67~101

(49.4~74.5)

7/8" (22)

85-110

(62.7-81.1)

7. Vacuum Drying and Leakage

Checking

7.1 Purpose of vacuum drying

•

Eliminating moisture in system to prevent the phe-

nomena of ice-blockage and copper oxidation

.

Ice-blockage shall cause abnormal operation of

system, while copper oxide shall damage

compressor.

•

Eliminating the non-condensable gas (air) in system

to prevent the components oxidizing, pressure fluc-

tuation and bad heat exchange during the operation

of system.

7.2 Selection of vacuum pump

•

The ultimate vacuum degree of vacuum pump shall

be -756mmHg or above.

•

Precision of vacuum pump shall reach 0.02mmHg or

above.

7.3 Operation procedure for vacuum

drying

Due to different construction environment, two kinds of

vacuum drying ways could be chosen, namely ordinary

vacuum drying and special vacuum drying.

7.3.1 Ordinary vacuum drying

1.

When conduct first vacuum drying, connect pressure

gauge to the infusing mouth of gas pipe and liquid pipe,

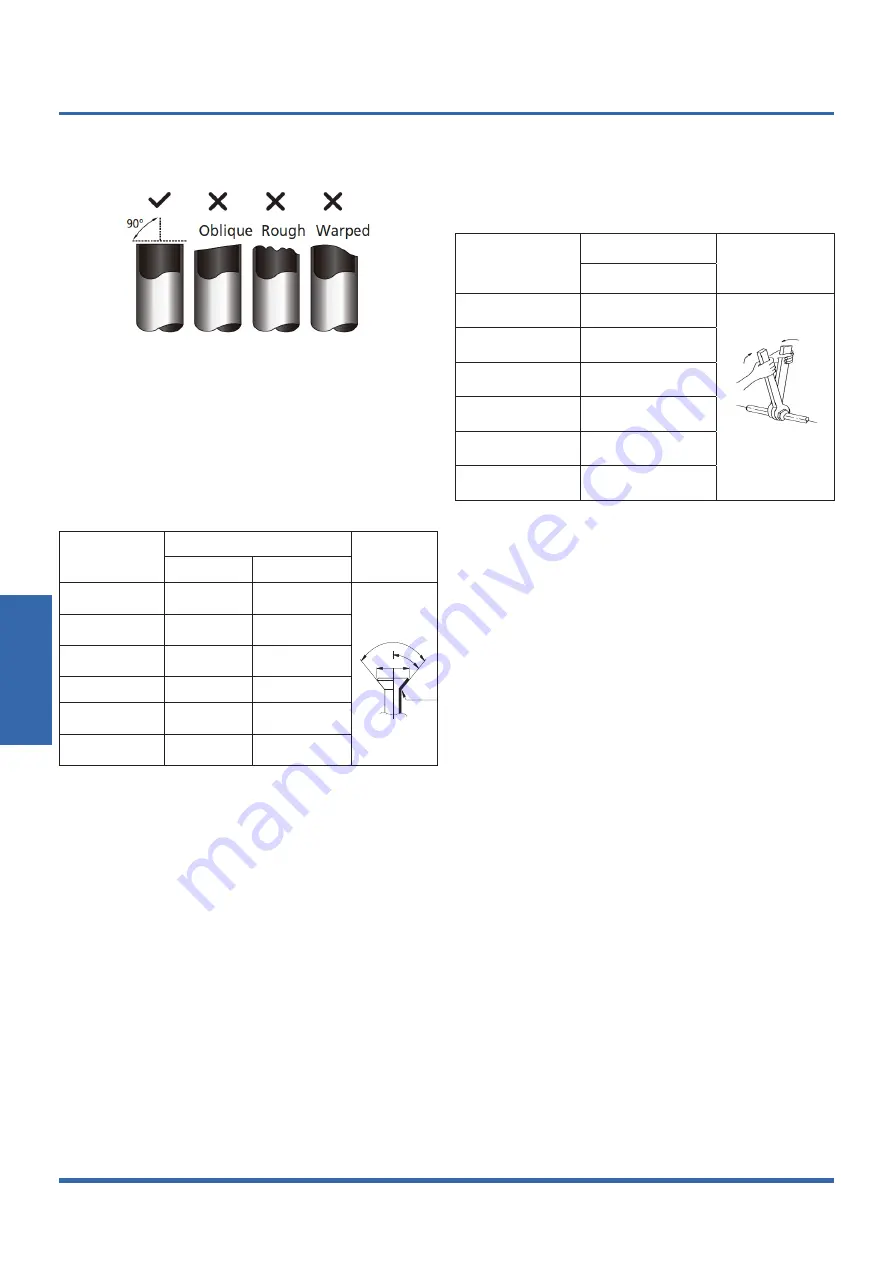

4.Cut the selected pipe with pipe cutter

•

Make the section flat and smooth.

5. Insulate the copper pipe

•

Before test operation, the joint parts should not be

heat insulated.

6. Flare the pipe

•

Insert a flare nut into the pipe before flaring the

pipe

•

According to the following table to flare the pipe.

Pipe diameter

(inch(mm))

Flare dimension A (mm/inch)

Flare shape

Min

Max

1/4" (6.35)

8.4/0.33

8.7/0.34

R0.4~0.8

45

2

90

4

A

3/8" (9.52)

13.2/0.52

13.5/0.53

1/2" (12.7)

16.2/0.64

16.5/0.65

5/8" (15.9)

19.2/0.76

19.7/0.78

3/4" (19)

23.2/0.91

23.7/0.93

7/8" (22)

26.4/1.04

26.9/1.06

•

After flared the pipe, the opening part must be seal

by end cover or adhesive tape to avoid duct or exog-

enous impurity come into the pipe.

7. Drill holes if the pipes need to pass the wall.

8. According to the field condition to bend the pipes so

that it can pass the wall smoothly.

9. Bind and wrap the wire together with the insulated pipe

if necessary.

10. Set the wall conduit

11. Set the supporter for the pipe.

12. Locate the pipe and fix it by supporter

•

For horizontal refrigerant pipe, the distance be-

tween supporters should not be exceed 1m.

•

For vertical refrigerant pipe, the distance between

supporters should not be exceed 1.5m.

13. Connect the pipe to indoor unit and outdoor unit by

using two spanners.

Содержание KSDA-35 DVR14

Страница 7: ...Specifications Page 7 3 Dimensional Drawings 3 1 Indoor Unit...

Страница 8: ...Specifications Page 8 3 2 Outdoor Unit KUE 35 DVR13...

Страница 9: ...Specifications Page 9 KUE 52 DVR13...

Страница 10: ...Specifications Page 10 4 Centre of Gravity KUE 35 DVR13 KUE 52 DVR13...

Страница 14: ...Specifications Page 14 KUE 35 DVR13 KUE 52 DVR13...

Страница 49: ......