PRELIMINARY

Subject

to

Revision

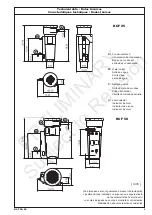

KCF 25, 50

4

The waste water destined for indirect discharge must not exceed

a hydrocarbon concentration of 20 ppm.

Please note that the national legal limit values for indirect dis-

charge may vary regionally.

Please check if your KCF type corresponds to

these instructions.

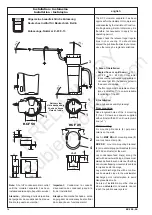

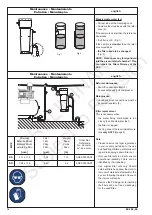

Application:

The KCF unit is designed for the treatment of demulsifiable

compressor condensates in compliance with legal require-

ments. Your local “lower-level water authority” needs to

be notified about the operation of the oil-water separator.

•

KFC 25

: Media / ambient temperature: 41...140 °F

KFC 50

: Media temperature:

41...140 °F

Ambient temperature:

23...140 °F

•

KFC only suitable for stationary application

• KCF is not suitable for use in hazardous areas

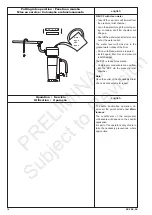

Danger!

Compressed air!

Contact with quickly or suddenly escaping compressed air

or with bursting plant components carries a risk of serious

injury or death.

Caution!

Oil-contaminated condensate!

Oil-contaminated condensate contains substances that

are hazardous both to health and the environment. These

substances may cause irritation or damage to the skin, eyes

and mucous linings. Oil-contaminated condensate must

not be allowed to get into the sewer system, water bodies

or the soil. Contaminated objects have to be cleaned or

disposed of according to the legal regulations.

•

Non-observance can result in injuries or damage to de-

vices! For the installation, the national regulations and

safety instructions in force also need to be observed!

• Only transport the KCF unit when it is empty!

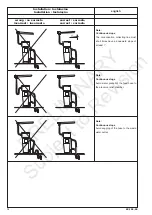

• Do not install the KCF outdoors!

Safety rules:

• It is absolutely essential to observe the present Instructions

for Installation and Operation.

Only use pressure-resistant installation material!

Ensure that condensate cannot squirt or splash onto

persons or objects.

• Protect the KCF against direct exposure to sunlight!

• KCF 50: in the case of installation in a room where there

is a danger of frost, a heating system has to be employed

onl(optional)!

•

Take measures to ensure that

oil or untreated condensate

cannot enter the sewer system in the event of damage!

•

Do not fill any

foreign liquid

or substances into the prese-

paration tank / KCF since this may impair the filter function!

• Only use original replacement filter sets!

In the event of significant differences compared with the

speci fications of the general technical approval, e.g. the

employment of non-original filters, the approval no longer cov

-

ers the usability of the KCF product. In such cases, individual

approval of the responsible local authority will be required.

Moreover, there will be no entitlement to the remedy of

defects within a 2-year period!

The operator’s duty of care includes the following:

Installation, siting, maintenance, repair or cleaning:

These tasks have to be carried out by a specialist firm, as

required by law, unless the operator himself possesses the

necessary qualifications and entitlements.

It should further be realised that the statutory limits for indirect

clean-water discharge into the sewer system may be subject

to regional variations.

This work has to be documented in the operating manual.

The operating manual and maintenance reports must be

filed and presented to the responsible local authority if

requested.

Supervision:

The operator must ensure through constant monitoring

that the KCF oil-water separator is in a leaktight condition

and functioning correctly.

• Check the oil-water separator for leaks regularly!

•

Check the outflowing clean water every week using the refer

-

ence test kit!

•

Always keep a spare filter set!

Caution!

Oil-contaminated condensate!

Oil-contaminated condensate contains substances that

are hazardous both to health and the environment. These

substances may cause irritation or damage to the skin, eyes

and mucous linings. Oil-contaminated condensate must

not be allowed to get into the sewer system, water bodies

or the soil. Contaminated objects have to be cleaned or

disposed of according to the legal regulations.