– 56 –

Indication

Level

Functions

Setting range

Remarks

S

XY feed forward / back speed

100~4000pps

500

(Setting possible in the unit of 10pps)

S

When the power supply is turned on, 0: Normal

0

oautomatic preparation is possible 1: Automatic preparation is

without pressing the READY key.

operated when the power

supply is ON.

S

While the needle stays in an upper 0: Holding disabled

0

position, a current is maintained in 1: Holding enabled

the main motor to make the needle

hard to down.

U

Method of XY enlargement/reduction 0: % setting

0

Displayed only for the IP200

scale rate setting (IP200 only)

1: Size setting

operation panel.

U

The origin is moved toward the

0: Standard

0

This setting is needed when

front by 5mm.

1: 5mm closer to the front

using the LK1904 presser foot

and patterns.

S

No. of pulses for work clamp foot

30~60

45

interlock wiper operation

S

The head falling detector switch

0: Normal

0

can be disabled.

1: Head falling detector switch

disabled

U

This function sets whether or not

0: Calling inoperative

Setting dep- Standard pattern Nos. 1 to 64

the calling of the pattern data is

1: Calling operative

ends on the can be individually set

operative.

model used. (Standard operation panel)

S

Initialization of model’s specifications

0:LK1900ASS

Setting

Contents of the memory switches

is executed.

1:LK1900AHS

values are are initialized to the state when

2:LK1900AFS

specified

delivered.

3:LK1900AMS

at left

The thread tension of each standard

4:LK1901ASS

according pattern is initialized to the state

5:LK1902ASS

to models. when delivered.

6:LK1902AHS

All the registrations patterns

7:LK1903ASS-301

and cycles are deleted.

8:LK1903ASS-302

9:LK1903ASS-311/BR35

10:LK1903ASS-312/BR35

11:LK1900AWS

U

Grease-up error

The number of stitches is

Only clearing possible with the

counted based on drive,

RESET key.

sewing machine.

Clearing should be done after

the completion of grease-up action.

U

Pattern registration is carried out.

U

Cycle sewing registration is carried out.

S

Test mode is assumed.

State when

delivered

Содержание LK-1900A

Страница 20: ... 16 10 Hook adjustment Standard Adjustment 0mm 0mm 7 5mm 0 05 0 1mm For DPX5 For DPX17 ...

Страница 87: ... 83 Grease Grease 3 Thread tension area 4 Thread trimmer area Grease Juki Grease A Grease Grease Juki Grease A ...

Страница 88: ... 84 Grease Grease Grease Templex N2 Grease Templex N2 Grease Grease Grease Grease Grease 5 Feed area ...

Страница 90: ... 86 Grease Grease Grease Grease Grease 8 Needle thread clamp mechanism area ...

Страница 91: ... 87 Grease Grease A Grease Grease Grease Grease 9 LK 1901A relations ...

Страница 92: ... 88 10 LK 1903A relations Grease Grease ...

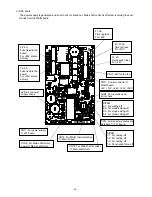

Страница 114: ... 111 12 Circuit diagrams 1 Block diagram A ...

Страница 115: ... 112 2 Power supply circuit diagram A ...

Страница 116: ... 113 3 Power supply circuit diagram B ...

Страница 117: ... 114 4 Power supply circuit diagram C ...

Страница 118: ... 115 5 Servo motor circuit diagram ...

Страница 119: ... 116 6 Sensor pedal VR circuit diagram ...

Страница 120: ... 117 7 MAIN PANEL board circuit diagram ...

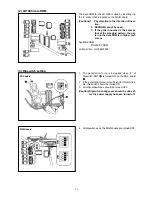

Страница 121: ... 118 8 Motor solenoid circuit diagram Thread trimmer Lifting the work clamp foot motor ...