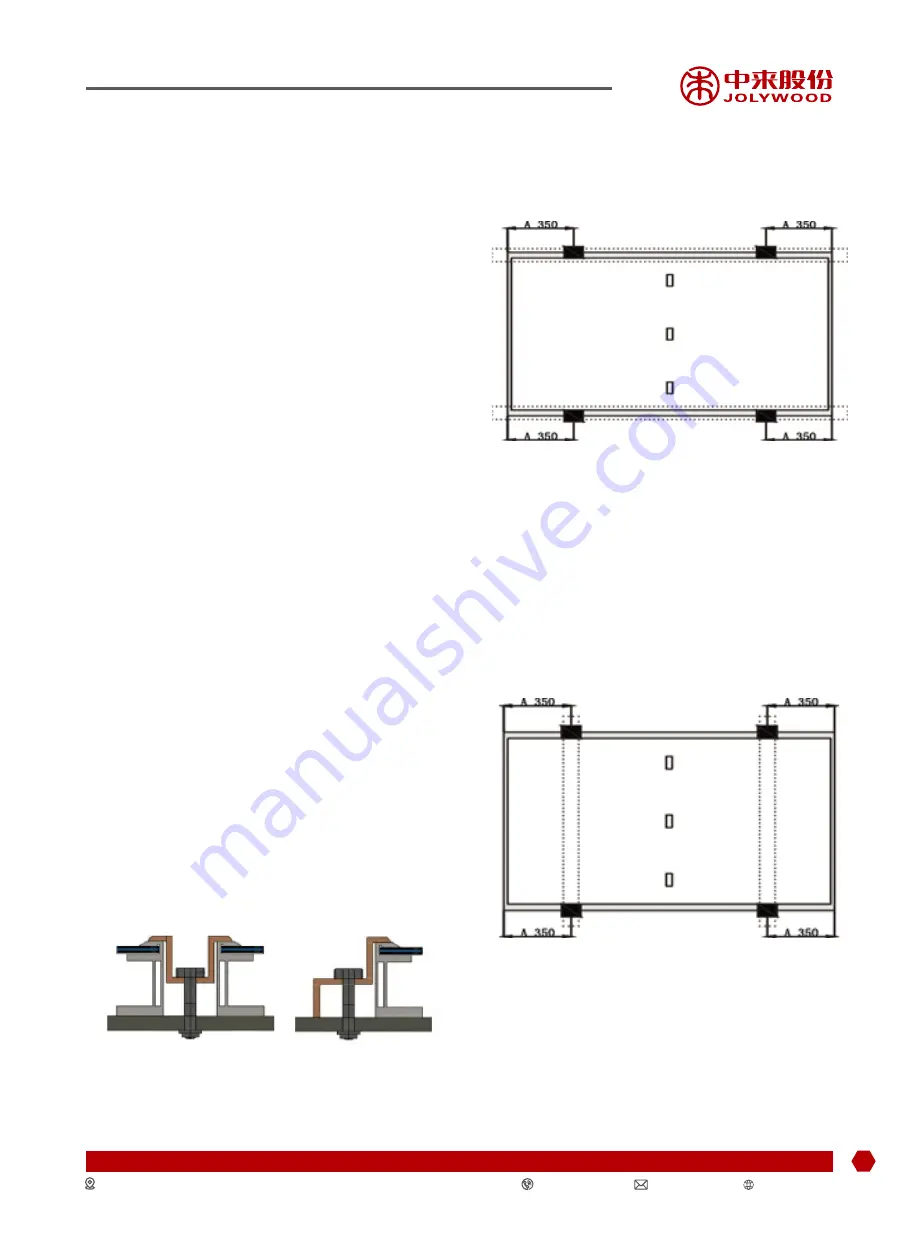

Fixture installation meth:

①frame ②clip ③ M8 bolt ④mounting rail

④

②

③

①

5.2 Mechanical installation and

precautions

5.3 Framed Bifacial Double-Glass

Modules (installation with clamps)

Modules could be mounted with clamps

or bezels. Modules Installation must be

carried out according to the following

examples and recommendations. If the

installation method is d i ff e r e n t f r o m

below methods, please consult Jolywood

local technical support or after-sales, to

obtain the consent of Jolywood, otherwise

when the modules is damaged, the limit

warranty would be invalid.

The mechanical load of the module

(including snow and wind loads) depends

o n t h e w a y o f m o d u l e i n sta l l e d . T h e

mechanical load should be calculated

by the professional s y st e m d e s i g n e r

b a s e d o n a c t u a l c o n d i t i o n s a n d en-

v i r o n m e n t a l . M o r e o v e r, i t d o e s n o t

withstand the excessive force generated

by the thermal expansion of the support

structure. The drain hole should not be

blocked under any conditions during

installation or use.

Edge Clamp& Middle Clamp:

9

Jolywood (Taizhou) Solar Technology Co.,Ltd.

Kaiyang Rd., Jiangyan Economic Development zone, Taizhou City, Jiangsu Province, P. R. China

www.jolywood.cn

+86-523-8061 2361

Mounted with 4 clamps along the long frame.

A=350mm±30mm.

C-shaped steel parallel to the long frame.

Clamp: height=30mm,width=40-50mm.

Maximum load: front ≤2400pa back ≤2400pa.

Mounted with 4 clamps along the long frame.

A=350mm±30mm.

C-shaped steel perpendicular to the long frame.

Clamp: height=30mm,width=40-50mm.

Maximum load: front ≤5400pa back ≤2400pa.

Installation Manual

- Jolywood N-type Mono-crystalline Double Glass Module

①

③

④

②