RXB PLUS ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

070.101-IOM (JAN 13)

Page 37

1.

.If.a.single.oil.filter.is.installed,.push.

[STOP]

key.to.shutdown.

the.unit...Open.disconnect.switches.for.the.compressor.and.

(if.applicable).oil.pump.motor.starters.

2.

.Close.discharge.service.valve..SLOWLY.vent.the.sepa-

rator.to.low-side.system.pressure.using.the.suction.check.

valve.bypass..Close.suction.valve.and.suction.check.valve.

bypass..

NOTE: Recover or transfer all refrigerant vapor,

in accordance with local ordinances, before opening to

atmosphere. The oil filter cartridge MUST be equalized

to atmospheric pressure before opening.

Oil-entrained refrigerant may vapor-

ize, causing a pressure increase.

Repeat venting and recovery pro-

cedure, if necessary.

3.

Remove. the. plug. from. the. bottom. of. the. filter. canister.

and.drain.the.oil..Remove.the.canister.cover.and.discard.the.

gasket..Remove.the.screws.securing.the.filter.assembly..Pull.

the.filter.assembly.from.the.canister.and.discard.the.gasket.

and.the.element.

4.

Flush.the.canister.with.clean.Frick.refrigeration.oil;.wipe.

dry.with.a.clean,.lint-free.cloth;.and.replace.the.plug.

5.

.Install.a.new.element.and.tighten.the.nut.on.the.end.plate.

to.10.ft-lb.torque..Then,.while.holding.the.nut.with.a.wrench,.

apply.a.second.nut.to.act.as.a.lock.nut..Replace.the.gasket.

and.reinstall.the.filter.assembly.into.canister,.securing.with.

screws.tightened.to.7.ft-lb.torque...Fill.the.canister.with.new.

Frick.refrigeration.oil..Replace.the.gasket.and.reinstall.the.

canister.cover..Torque.cover.bolts.first.to.finger.tight,.then.65.

ft-lb,.then.130.ft-lb.

6.

Isolate.the.low.pressure.transducer,.PE-4,.to.prevent.dam-

age.during.pressurization.and.leak.test.

7.

Pressurize.and.leak.test..Evacuate.the.unit.to.29.88".hg.

(1000.microns).

8.

Open.suction.and.discharge.the.service.valves,.and.the.

low.pressure.transducer..Readjust.suction.check.valve.by-

pass..Close.disconnect.switches.for.the.compressor.and.(if.

applicable).the.oil.pump.motor.starters..Start.the.unit.

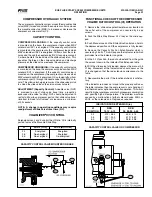

OIL FILTER(s) - DUAL

RXB

.compressor.units.are.furnished.with.one.main.oil.filter..

A.second.filter.is.installed.as.optional.equip.ment.to.minimize.

down.time.and.reduce.refrigerant.loss.

1.

If.dual.oil.filters.are.furnished,.open.the.inlet.and.then.the.

outlet.service.valves.of.the.standby.filter.

Open outlet and inlet service valves

SLOWLY to prevent a sudden pres-

sure drop which could cause an oil

filter differential cutout.

2.

.Close.the.outlet.and.then.the.inlet.service.valves.of.the.filter.

being.serviced..Open.the.bleed.valve.on.the.filter.canister.

and.

SLOWLY

.purge.to.atmospheric.pressure.

3.

. Follow. instructions. 3,. 4,. and. 5. under. “OIL. FILTER. -.

SINGLE.”

4.

.Place.the.unit.back.into.service.

OIL RETURN STRAINER

The.unit.must.be.shut.down.and.equalized.to.atmospheric.

pressure...

NOTE: Recover or transfer all refrigerant vapor

in accordance with local ordinances before opening to

atmosphere.

1.

.Remove.the.large.plug.from.the.bottom.of.the.strainer,.

remove.the.element.from.the.strainer.

2.

.Wash.the.element.in.solvent.and.blow.it.clean.with.air.

3.

.Replace.the.element.and.the.large.plug.

4.

.Open.the.valves.closed.in.Step.1.and.check.for.leak.age..

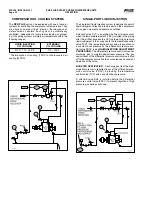

OIL PUMP STRAINER (Optional)

To.clean.the.full-lube.oil.pump.strainer,.the.unit.must.be.shut.

down..The.proce.dure.is.as.follows:

1.

. Shut. .down. the. unit. and. open. the. discon.nect. switches.

for.the.compressor.and.(if.applicable).the.oil.pump.motor.

starters..Isolate.and.equalize.unit.to.atmospheric.pressure.

(See. General. Instructions. for. Replacing. Compressor. Unit.

Components).

2.

.Close.the.inlet.service.valve.

3.

.Open.the.drain.valve.located.in.the.strainer.cover.and.drain.

the.oil.into.a.container.

4.

.Remove.the.capscrews.securing.the.strainer.cover,.strainer.

cover.gasket,.and.element..Retain.the.gasket.

5.

.Wash.the.element.in.solvent.and.blow.it.clean.with.air.

6.

.Wipe.the.strainer.body.cavity.clean.with.a.lint-free.clean.

cloth.

7.

.Replace.the.cleaned.element.and.gasket,.then.reattach.

the.cover.using.the.retained.capscrews.

8.

.Close.the.drain.valve.and.open.the.strainer.inlet.service.

valve.

9.

.Check.for.leakage.

10.

.Open.suction.and.discharge.valves.and.readjust.suc-

tion.check.valve.bypass.(if.required)..Close.the.disconnect.

switches.for.the.compressor.and.(if.applicable).the.oil.pump.

motor.starters.

11.

.Start.the.unit.

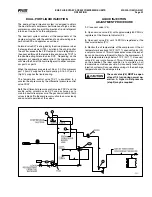

LIQUID INJECTION STRAINER

To.clean.the.liquid.injection.strainer,.the.unit.must.be.shut.

down..The.procedure.is.as.follows:

1.

.Shut..down.unit.and.open.the.discon.nect.switches.for.the.

compressor.and.(if.applicable).oil.pump.motor.starters..Iso-

late.and.equalize.unit.to.atmospheric.pressure.(See.General.

Instructions.for.Replacing.Compressor.Unit.Components).

2.

.Close.the.liquid.supply.service.valve.located.before.the.

liquid.solenoid.

3. Immediately screw in the manual solenoid valve stem

to relieve liquid refrigerant pres sure trapped between

the solenoid and the service valve.

Содержание Frick RXB Plus 12

Страница 65: ...RXB PLUS ROTARY SCREW COMPRESSOR UNITS MAINTENANCE 070 101 IOM JAN 13 Page 65 OPERATING LOG SHEET ...

Страница 66: ......

Страница 67: ......