15.0 REGULAR MAINTENANCE

User should check oil level at least once every two weeks. A

change in oil level would be an indication of oil leaks in the lines

or in the hydraulic cylinder and should be checked.

1. Inspect all superstructure fasteners. Tighten if necessary.

2. Inspect cables for fraying. If fraying is evident, DO NOT USE THE LIFT.

Replace cables.

3. Grease swivel arm rub bars.

4. Inspect arms for overload drooping from stretched or loosened arm bolts.

Have loose bolts tightened and stretched bolts replaced.

5. Inspect the height adapters for damage and replace if necessary.

6. Use a spray can of silicon lubricant on piston surfaces.

NOTE:

Clean and

wipe down pistons with a clean dry cloth before applying the silicon

lubricant.

23

Содержание 40HP210ES

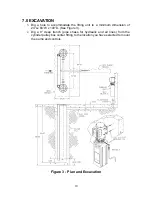

Страница 9: ...Figure 1 Bay Layout Option A 8 ...

Страница 10: ...Figure 2 Bay Layout Option B 9 ...

Страница 12: ...Figure 4 Elevation 11 ...

Страница 14: ...Figure 5 Cable Routing 13 ...

Страница 15: ...Figure 6 Hydraulic and Air Connections 14 ...

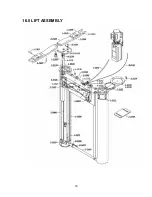

Страница 25: ...16 0 LIFT ASSEMBLY 24 ...

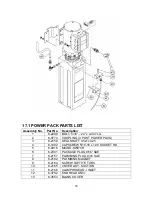

Страница 27: ...3 1026 1 Pump Stand Bolt Down Standard Not shown in figure 26 ...

Страница 28: ...17 0 POWER PACK ASSEMBLY 27 ...

Страница 31: ...18 0 AVAILABLE ACCESSORIES Figure 10 Truck Height Extension Adapter Part No 3 1028 Set of 4 30 ...