Chlorinator C 2700

BW 2 03 01 / 7

Operating and Maintenance Instructions

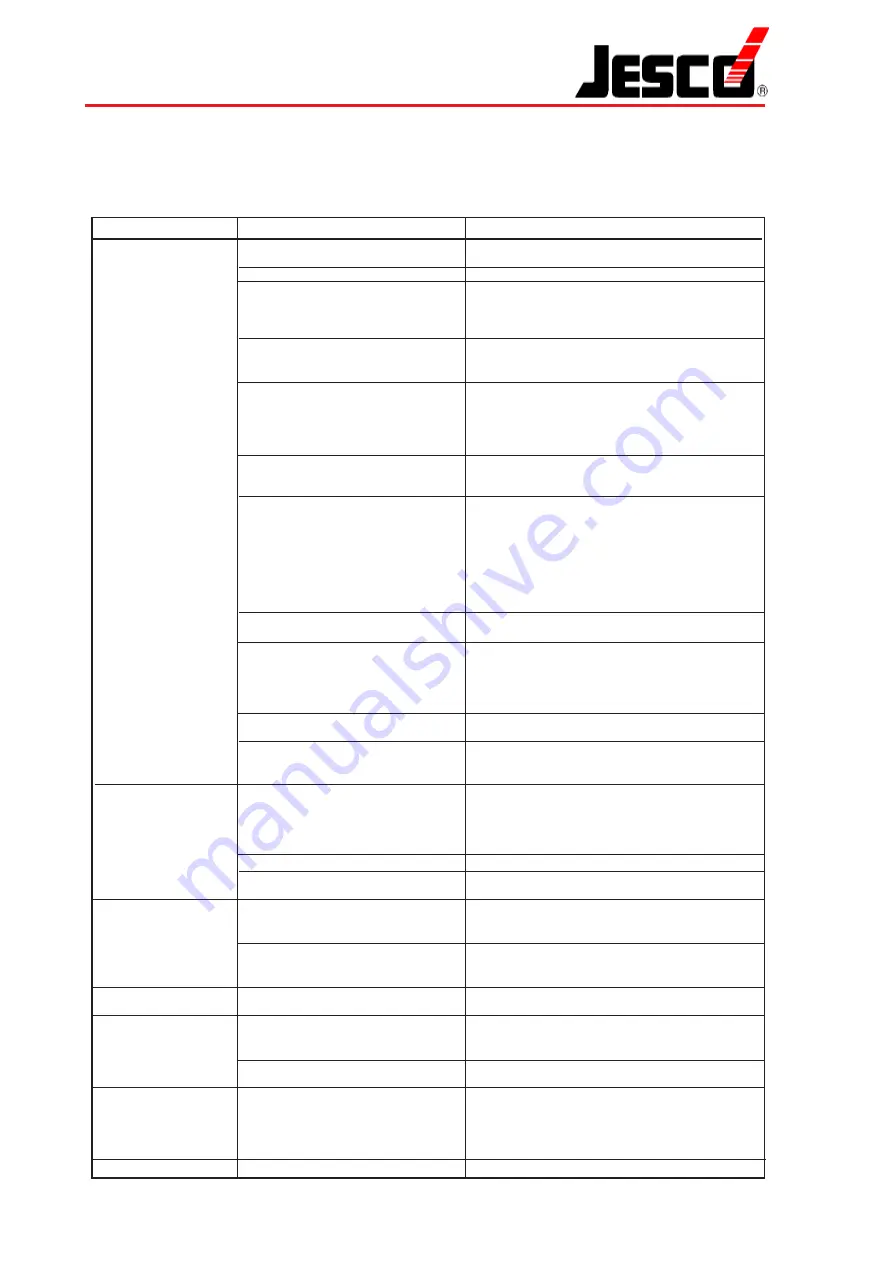

Type of fault

Possible cause

Remedy

No display or

Chlorine barrel empty, indicated by

Connect new barrel.

insufficient display

low chlorine gas pressure.

on flow meter

Connecting valve closed.

Open valve.

Chlorine gas line bent or blocked.

Close chlorine barrel,

drain off line and device,

stop motive water supply, dismantle chlorine

gas line and clean or replace it.

Blocked filter before inlet valve,

Clean or replace filter.

indicated by low chlorine volume

despite high vacuum.

Motive water pressure too low.

Compare ejector characteristics sheet with

acutal pressure values, install booster pump,

if necessary.

Open reducing valve.

Back pressure too high.

Excessive pressure drop in dirt trap

Remove dirt trap from reducing valve

of motive water.

and clean filter.

Also flush water lines.

Ejector blocked, contaminated or

Remove ejector, clean PVC inlet nozzle and outlet

encrusted by deposits (possibly caused

borehole using hypochloric acid and rinse well in

by decarbonization in the diffusor).

water. If possible, apply higher concentration of

chlorine (1...2g/m

3

) in the solution to obtain more

HCL. Set motive pressure before ejector as low as

possible but make sure that the maximum chlorine

still be metered.

Block solution injection fitting.

Remove and clean solution injection fitting and

check if the valve is fully open.

Excessive back pressure caused by bent

Lay line with sufficiently large bends: PVC

or blocked solution line. Excessive

lines may have restricted cross-sections due to

pressure losses due to friction in pipes

wrong gluing.

or fittings.

Check joints.

Float stuck in flow meter glass.

Clean flow meter as described under

Maintenance.

Components under vacuum prime

Check the joints of the suction line, the ejector

external air.

non-return valve and the flow meter glass holder.

Metered volume

Inlet valve blocked.

Remove inlet valve as described under

does not increase

Maintenance.

when adjusting screw

is opened.

Vacuum primed by the ejector is too low.

See above.

Float stuck in the flow meter glass.

Clean the flow meter glass as described under

Maintenance.

Chlorine odor in the

Gas lines leak.

Close barrel connecting valve immediately and drain

room.

off lines using the ejector. Leakage test as described

under Startup.

Safety valve integrated in device blows

Remove and clean inlet valve as described under

off. Inlet valve is dirty or damaged.

Maintenance. Replace damaged parts.

Vent line primes

Diaphragm suspension leaking or

Dismantle device and check all parts.

constantly air.

diaphragm torn.

Reassemble very carefully.

Water in the device.

Ejector non-return valve defective.

Remove and dismantle non-return valve.

Clean it and replace defective parts. Install

motor ball cock (see flow diagram, item 12).

End of vent line not protected

Lay vent line correctly. Line end must show down.

against entry of water.

Re-liquefied chlorine

Temperature in eqiupment room too low

Increase temperature in the equipment room.

indicated by yellow

in comparison to chlorine storage room.

Install heating block or pressure reducing valve.

liquid in measuring

Install drop separator.

glass and decomposed

PVC parts.

Icing.

Chlorine consumption too high.

Connect more chlorine barrels.

Troubleshooting

Lutz-Jesco GmbH

Improved changes are always reserved without notice.