Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to cooktop before servicing, unless

testing requires power.

©2004 Maytag Services

16023537

13

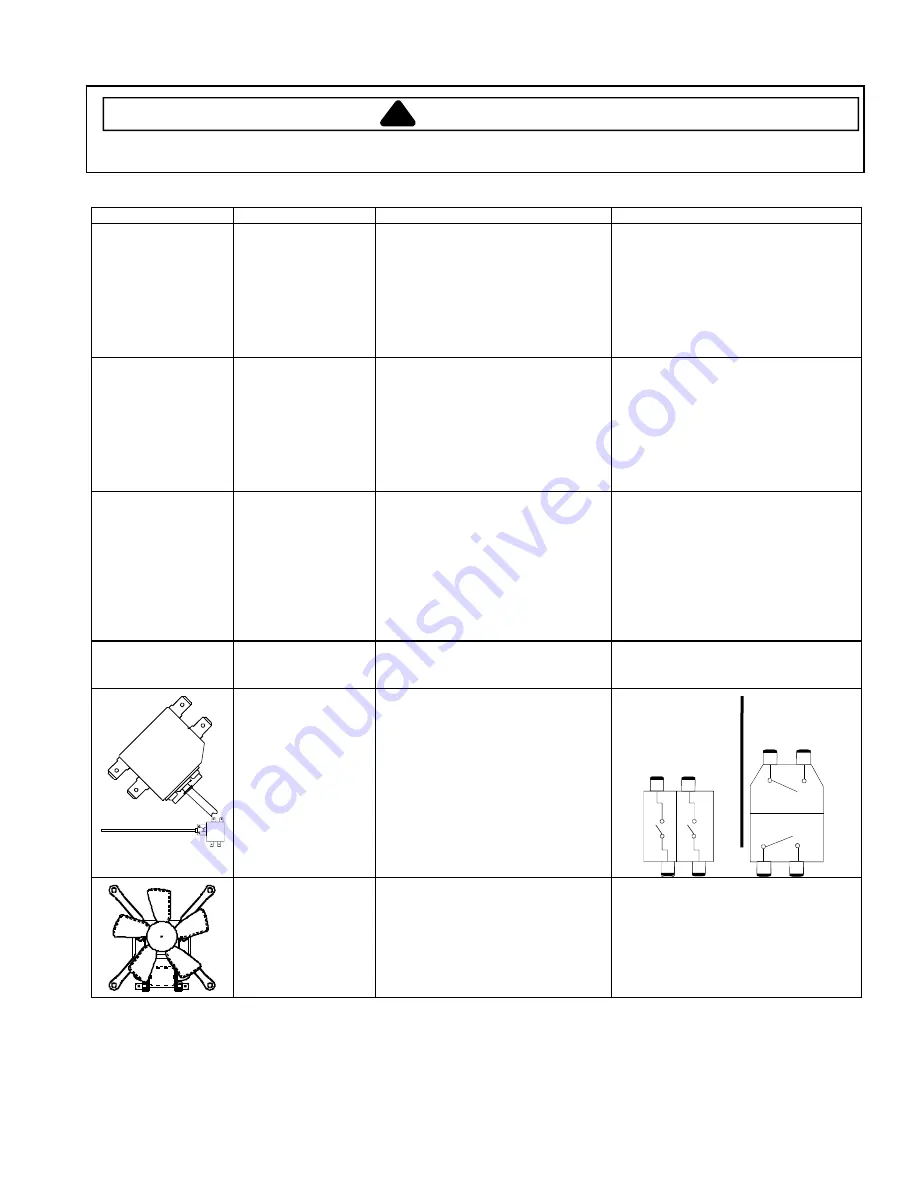

Component Testing

Illustration Component

Test

Procedure

Results

Power supply

Disconnect power from cooktop and

verify circuit breakers/fuses are not

tripped. Check fuse rating. Check

terminals at terminal block for

tightness. Verify cooktop service wires

are properly connected, and are in

good condition. Check for proper

voltage with a voltmeter .........................

Refer to schematic diagram for correct

voltage measurements

Internal wiring

Disconnect power from cooktop, place

one ohmmeter lead at the terminal

block, the other lead at the line terminal

of the malfunctioning part. Use the

appropriate wiring diagram to repeat this

procedure from the output of the control

to the component, until each section is

checked. A visual check of the wiring

will often determine the fault location .....

Continuity

1200 W

−

6”

1800 W

−

7”

2000 W

−

8”

3000 W

−

9/6”

(Dual element)

3000 W

−

12/9/6”

(Triple element)

Ribbon radiant

elements

Remove one wire lead from element

and measure resistance of element .......

Dual element

−

1400 + 1600 = 3000 W....

Triple element

−

1050/2200/2700 W ........

Continuity (approximately), if not replace.

6”

−

1200W: 44 to 49

Ω

7”

−

1800W: 29 to 33

Ω

8”

−

2000W: 26 to 30

Ω

3000W: 1400 W Inner 53 to 59

Ω

1600 W Outer 38 to 42

Ω

Triple:

1050 W: 52 to 57

Ω

2200 W 24 to 28

Ω

2700 W 19 to 24

Ω

100 W

Warming element

Remove one wire lead from element

and measure resistance of element .......

Continuity, if not replace

6”

−

100W:

35 to 39

Ω

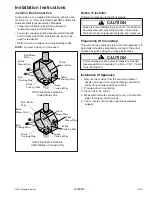

Approx

Ribbon surface

thermal limiter/hot

light switch

Turn surface element on and test for

voltage. See wiring diagram and

schematic ..............................................

1a

−

2a 240

VAC

1b

−

2b 120

VAC

Disconnect leads and measure

resistance on the following:

1a

−

2a room

temperature

−

continuity

1b

−

2b room

temperature

−

infinite

240 VAC

Electrovac

1b

1a

2a

2b

Hot light

Heater

circuit

circuit

Therm-O-Disc (TOD)

1b

2b

2a

1a

Hot light

Heater

circuit

circuit

Cooling fan

Remove wire leads from terminals and

measure resistance of the motor............

Verify voltage to cooling fan terminals....

Should indicate resistance. If infinite

ohms, replace cooling fan

120 VAC See Wiring Diagram/Schematic

for terminal identification

RPM: 2100 ± 400

Содержание JEC0530ADB

Страница 17: ...2004 Maytag Services 16023537 A 1 Appendix A...

Страница 21: ...2004 Maytag Services 16023537 B 1 Appendix B...