Troubleshooting Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to cooktop before servicing, unless

testing requires power.

10

16023537

©2004 Maytag Services

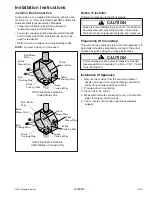

CAUTION

!

• Verify proper grounding before checking for trouble.

• Be careful of the high voltage circuit.

•

Do not touch any part of the circuit on the printed circuit board, since static electric discharge may damage the

control panel. Always touch yourself to ground while working on this panel to discharge any static charge built

up on your body.

Electronic Touch Control Troubleshooting

Symptom Possible

Cause Correction

No element operation (power

board disables power to

elements)

Communication failure.....................................

(power board disables power to elements

after 10 second communication loss

between control board and power board)

•

Verify power to unit.

•

Verify power to power board.

•

Check connection between power

and control board.

LOCKED

LED illuminated,

electronic control locked when

power applied (dual, triple or

bridge elements not selected),

no audible alarm

Checksum failure (control board) ....................

•

Replace control board.

No LEDs, electronic control

locked, 1 audible beep

ON

LED failure (control board) ........................

•

Replace control board.

2 LEDs flash, (user must lock

cooktop to evoke this display),

no element operation, no

audible alarm

Hardware watchdog error (power board).........

•

Replace power board.

3 LEDs flash, electronic control

locked, 1 audible beep

Redundant

OFF

key input line is not

operating properly (control board) ...................

•

Replace control board.

6 LEDs flash, electronic control

locked, no audible alarm

A/D failure (control board) ...............................

•

Replace control board.

7 LEDs flash, electronic control

locked, no audible alarm

Shorted temperature probe (power board) ......

Shorted input (power board)............................

•

Verify sensor resistance and

connections.

•

If symptoms persist, replace

power board.

8 LEDs flash, electronic control

locked, no audible alarm

Open temperature probe or open input

(power board) ..................................................

•

Verify sensor resistance.

•

If symptoms persist, replace

power board.

9 LEDs flash, electronic control

locked, no audible alarm

A/D failure (power board) ................................

•

Replace power board.

10 LEDs flash, electronic control

locked, no audible alarm

RAM test failure (power board)........................

•

Replace power board.

11 LEDs flash, electronic control

locked, no audible alarm

Checksum failure (power board) .....................

•

Replace power board.

12 LEDs flash, electronic control

locked, no audible alarm

Communication failure (control board

*

) ...........

•

Verify connections.

•

If symptoms persist, replace

control board.

All LEDs flash, no element

operation, 3 short audible beeps

(continuous

**

)

Over temperature indication ............................

Multiple keys detected (control board),

shorted key ......................................................

•

Verify sensor resistance.

•

If symptoms persist, replace

control board.

*Control Board resets the Power Board every 15 seconds.

**Audible alarm (beeps) will not occur if all elements are turned off.

Содержание JEC0530ADB

Страница 17: ...2004 Maytag Services 16023537 A 1 Appendix A...

Страница 21: ...2004 Maytag Services 16023537 B 1 Appendix B...