14

3)

Coupling

1.

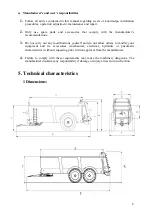

See chapter 5, Technical characteristics, page 8.

2.

Hitching the machine to the tractor must only be carried out using the tractor’s rear

coupling points provided for this purpose.

3.

Check the compatibility of the machine with the tractor (minimum engine power, type

of coupling, tractor PTO characteristics, etc.). Keep clear of the area between the tractor

and the machine until you have stopped the tractor’s engine and removed the starter key.

4.

Keep clear of the area between the tractor and the machine during any lifting manoeuvre

of the tractor.

5.

When manoeuvring, select the lowest possible tractor gear ratio. When coupling, attach

the equipment’s electric control unit in the tractor cab, ensuring that it cannot move

during operations.

6.

Once the equipment has been coupled up, the hitch must be locked. Check the coupling

is correctly locked and in good condition before any movement.

7.

Check that the equipment’s coupling does not create either an overload or poor weight

distribution on the tractor that might compromise stability:

- Do not exceed the maximum allowed loading for the tractor and equipment

attachment points.

- Where necessary, fit ballast weights to the mounts provided for this purpose in

accordance with the tractor manufacturer’s recommendations.

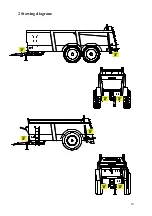

Couple the equipment to a tractor whose linkage is equipped with lateral and vertical

locking devices.

8.

To drive on roads, respect the coupling height specified in the instruction manual.

4)

PTO (power take-off) / Drive shaft

1.

Read and learn the manufacturer’s instructions for the drive shaft, attached to the

transmission.

2.

Check that the PTO guards are in place and in a good condition. Replace them

immediately if damaged.

3.

Adjust the length between the tractor and the machine, retaining maximum engagement.

4.

The minimum engagement length is

250mm

. See white instruction stickers placed on

the front of the unit, n° 892 640 (page 12).

Before each operation, check that the drive shaft is in good condition and that it is fitted

and locked correctly.

5.

Only use the drive shaft provided with the equipment or recommended by the

manufacturer.

6.

Check before each use that the speed and direction of rotation of the tractor PTO are

compatible with the planned usage of the equipment.