Model LJ Pool and Spa Heater

Page 11

4.2. Special Precautions for Propane Gas

Liquefied petroleum (LP) gas is heavier than air.

Therefore, do not install pool heaters using LP gas in

pits or locations where gas might collect. Locate

heaters a safe distance from LP gas storage and filling

equipment. Consult local codes and fire protection

authorities about specific installation restrictions.

SECTION 5.

Water Connections

5.1 Water Piping

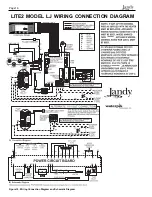

Figure 6 illustrates typical piping for pool equip-

ment in pool/spa combination pools.

The heater must be protected from back-

siphoning of water, which can result in dry starts. If

there is any chance of back-siphoning, provide a check

valve between the pool and the filter pump inlet.

Arrangement of pool system components other

than as illustrated in these diagrams can affect the

operation of the heaters water pressure switch.

Location of the heater above or below the pool water

surface can also affect operation of the switch. In

general, the pressure switch can be adjusted to

accommodate this effect if the heater water connec-

tions are no more than six feet below the pool water

surface and no more than 15 feet above it. See

instructions for pressure switch adjustment (Section

7.2) in the heater start-up section of this manual for

more information about this.

Note that when pool equipment is located below

the pool surface a leak can result in large scale water

loss or flooding. Water Pik Technologies cannot be

responsible for such water loss or flooding or the

damage caused by either occurrence.

5.2 Check Valve Installation

For normal installations, do not install a shutoff

valve or any kind of variable restriction in the water

piping between the heater outlet and the pool/spa.

Install a check valve if there is any chance of

back-siphoning when the pump stops. Do not install any

other valve in the piping between the heater outlet and

the pool, unless it is being used as a diverter valve. For

special installations such as water connections below

the water level of the pool, or for other questions

contact the Jandy Technical Service department at

(707) 776-8200 ext. 260.

5.3 Automatic Flow Control Valve

The inlet/outlet header of the Lite2 comes

equipped with an automatic flow control valve. The

automatic flow control valve maintains the proper flow

through the heater at rates up to approximately 125

Gallons Per Minute (GPM) (475 liters per minute

[LPM]). If the filter system flow rate is higher than

approximately 125 GPM (475 LPM), install a manual

bypass valve (see Figure 6), then perform a tempera-

ture rise test (see Section 7.7) and adjust the flow

using the bypass valve until the proper temperature

rise is obtained.

5.4 Reversible Water Connections

Water Pik Technologies ships the Lite2 heater

with the water connections on the right side. The Lite2

heater can be installed with the water connections on

either side. It could be necessary, or helpful, to switch

the connections to the left side to improve access for

installation and service. Perform this modification

before installing the heater using the following proce-

dures:

1.

Remove heater door.

2.

Remove all 8 hex-head screws fastening the top

and lift the top assembly straight up (see Figure

7).

Figure 7. Heat exchanger reversal.